Combined technique for garbage filter liquor treatment

A landfill leachate and combined process technology, applied in the field of waste liquid treatment process, can solve the problems of high investment and treatment cost per ton of water, large area, abnormal system operation, etc. Small, solve the effect of high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

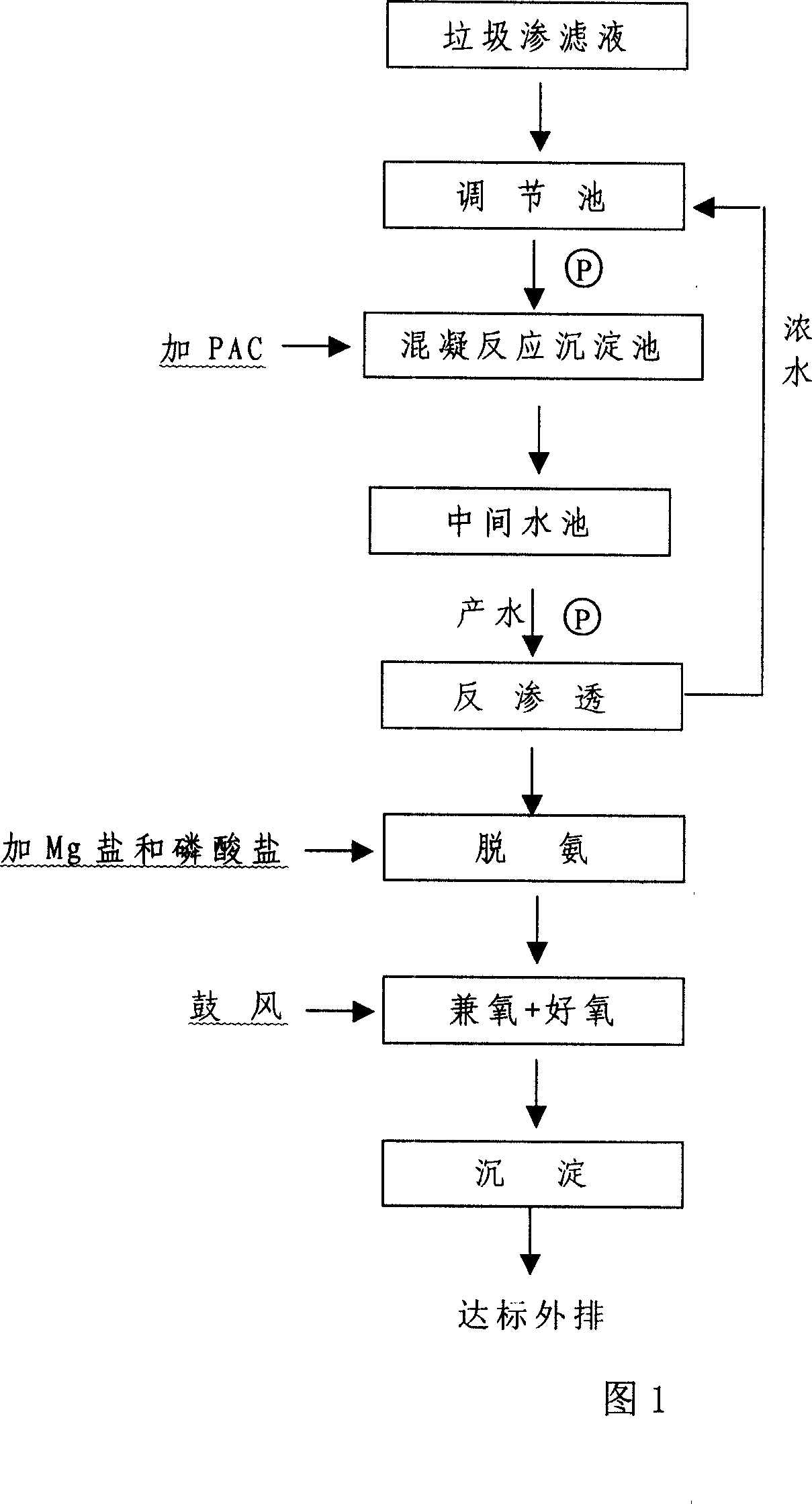

[0021] Referring to accompanying drawing 1, a combined landfill leachate treatment process collects the leachate from the landfill and flows into the adjustment tank, and installs a perforated aeration tube in the adjustment tank to fully aerate and mix, enhance the adjustment function, and prevent suspended solids from entering the adjustment tank. Sedimentation, uniform water quality and water volume, according to the design specifications, the air volume is 5.0m when the adjustment tank is aerated with perforated tubes for stirring 3 / (h·m 2 ).

[0022] The wastewater is pumped into the coagulation reaction sedimentation tank through the submersible pump, and an appropriate amount of flocculant PAC and coagulant PAM is added to the coagulation sedimentation tank. The weight ratio of PAC is generally between 0.05-0.5%, such as 0.2 % or 0.35%, the weight ratio of PAC to PAM is more suitable between 100:1-5, such as 100:2 or 100:4; the pH of the wastewater is controlled betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com