Device and method for recovering sulfuric acid from waste sulfuric acid generated in process of producing perylene series pigment

A waste sulfuric acid, a series of technologies, applied in the field of sulfuric acid devices, can solve the problems of difficult separation and decomposition, complex and stable structure, large molecular weight, etc., and achieve the effects of good energy saving effect, simple process and quick effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

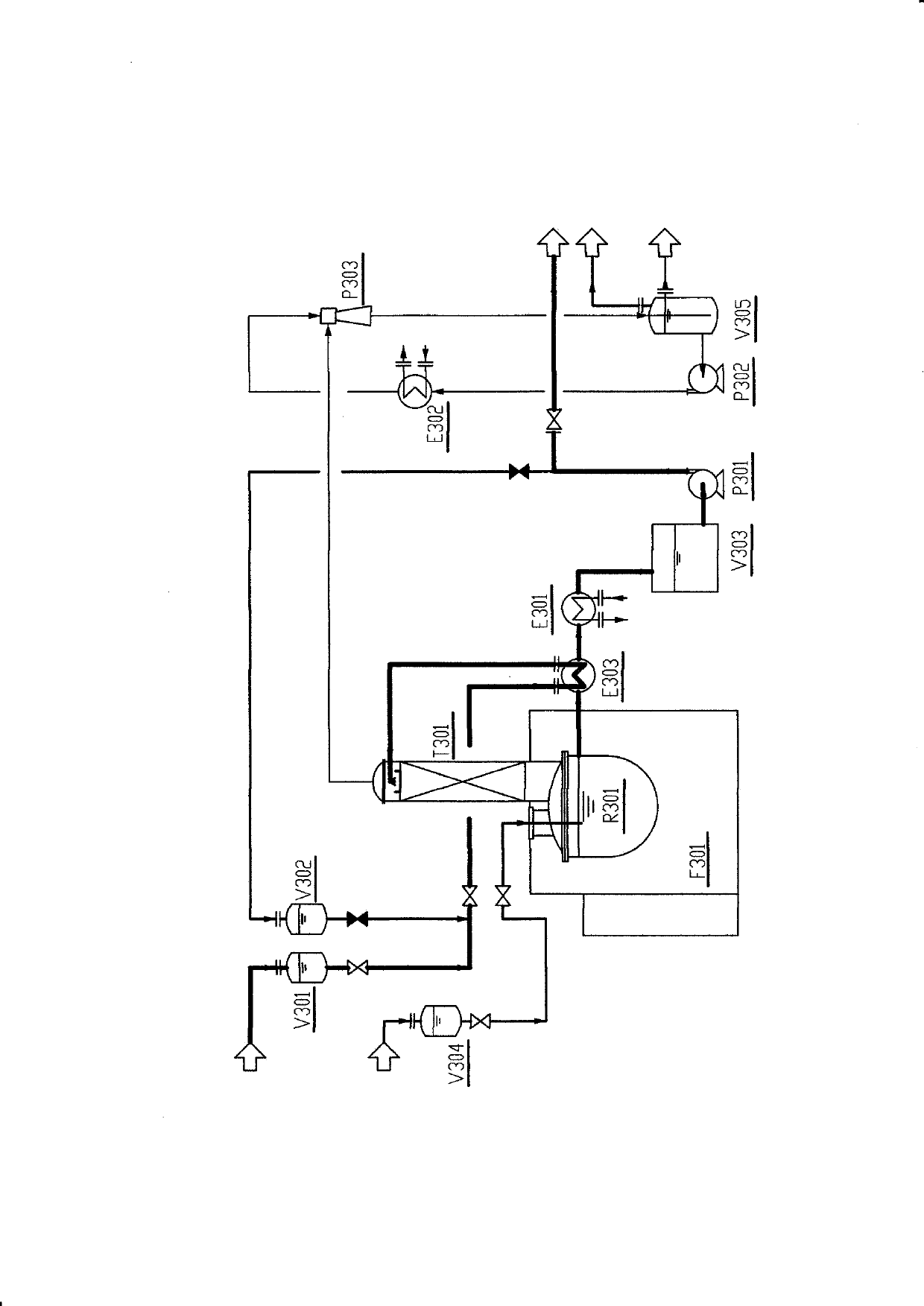

[0016] With reference to the accompanying drawings, the described device for recovering sulfuric acid in waste sulfuric acid includes a concentration furnace F301, a concentration pot R301 is installed on the concentration furnace F301, a pot cover is arranged on the top of the concentration pot R301, a fractionation tower T301 is arranged on the pot cover, and a fractionation tower T301 is installed in the fractionation tower. There are fillers, the fillers can be high silicon cast iron or glass or fluoroplastics, the bottom of the fractionation tower is connected to the concentration pot, the tube side of the dilute sulfuric acid preheater E303 is connected to the feed port of the fractionation tower T301 through pipelines, and the shell side of the dilute sulfuric acid preheater There is a pipeline connected to the shell-side inlet of the concentrated sulfuric acid cooler E301. The concentrated sulfuric acid cooler has a cooling water inlet and outlet for connection with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com