A kind of high-performance ultra-thin polypropylene capacitor film and its manufacturing method

A technology of polypropylene capacitors and polypropylene, which is applied in the field of high-performance ultra-thin polypropylene capacitor film and its manufacturing, can solve the problems of difficult miniaturization of high-power capacitors, differences in mechanical strength, obvious bow effect, etc., to reduce heat Effect of shrinkage, low shrinkage, and improvement of thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The polypropylene raw material whose isotacticity is greater than 98%, the ash content is less than 20ppm, and the melt index (MFI) is 2.6g / 10min is used. The raw materials are melted and plasticized at 260°C, processed through a filter, and extruded into a T-shaped die with a die temperature of 250°C to form thin sheets. The filter adopts a pleated filter core, and the filter is heated by oil vapor.

[0033] The above sheet is cooled and shaped by chilling roll and high-pressure air knife, wherein the air knife pressure is 110mbar; the chilling roll adopts a spiral groove flow channel, and the temperature of the air knife and chilling roll is 100°C. The thickness of the cast sheet obtained by shaping is 48 times the thickness of the designed product. Thick sheets are sequentially stretched through four sets of preheating rollers, and stretched synchronously under the condition that the stretching ratio is 6 times in the longitudinal direction and 8 times in the transv...

Embodiment 2

[0035] Adopt the same embodiment as Example 1, but the cast sheet thickness is 45 times of the design product thickness, and the draw ratio is 5 times in the longitudinal direction and 9 times in the transverse direction. The temperature of the preheating zone along the feeding direction gradually increases to 123°C, 133°C and 145°C; the temperature of the stretching zone is 150°C, 155°C, 160°C, 165°C; the temperature of the heat setting zone is 160°C, 155°C °C, 145 °C. The thickness of the finally obtained polypropylene capacitor film is 2.5 μm.

Embodiment 3

[0037] Adopt the same embodiment as Example 1, but the extrusion temperature is 250°C, the cast sheet thickness is 40 times the design product thickness, and the stretch ratio is 5 times in the longitudinal direction and 8 times in the transverse direction. The temperature of the preheating zone along the feeding direction gradually increases to 120°C, 130°C and 145°C; the temperature of the stretching zone is 148°C, 152°C, 158°C, 162°C; the heat setting zone is 160°C, 155°C, 145°C. The thickness of the finally obtained polypropylene capacitor film is 4.0 μm.

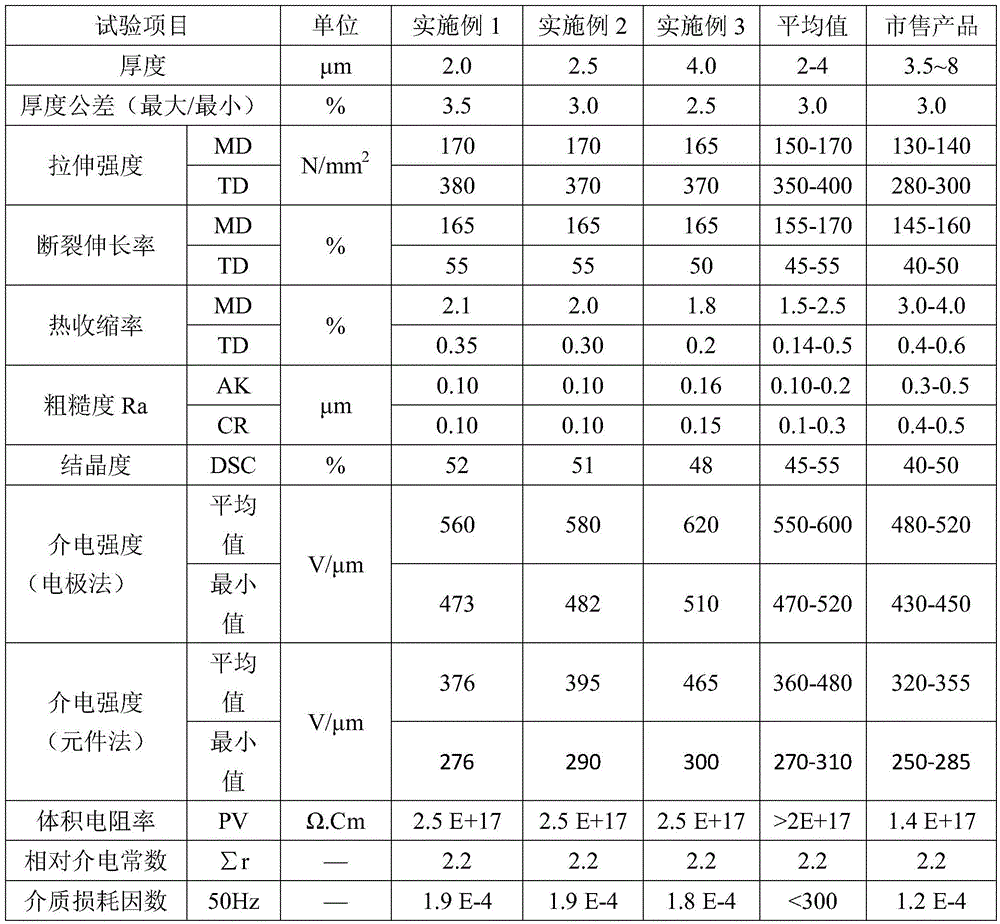

[0038] The main test method is GB / T12802, and the results are shown in Table 1.

[0039] Table 1

[0040]

[0041] From the examples and test results, the present invention selects high-purity electrical-grade polypropylene raw material and adopts the 2-4 μm ultra-thin biaxially stretched film polypropylene film prepared by a bidirectional simultaneous stretching process, and its heat resistance, dielectric strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com