A Casting Method of Single Crystal Superalloy Blade with Precise Control of Three-dimensional Crystal Orientation

A technology of crystal orientation and high temperature alloy, applied in the field of precision casting, can solve the problems of uncontrollable secondary crystallographic orientation, single crystal blade performance and qualification rate cannot be in line with international standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Casting technical scheme design:

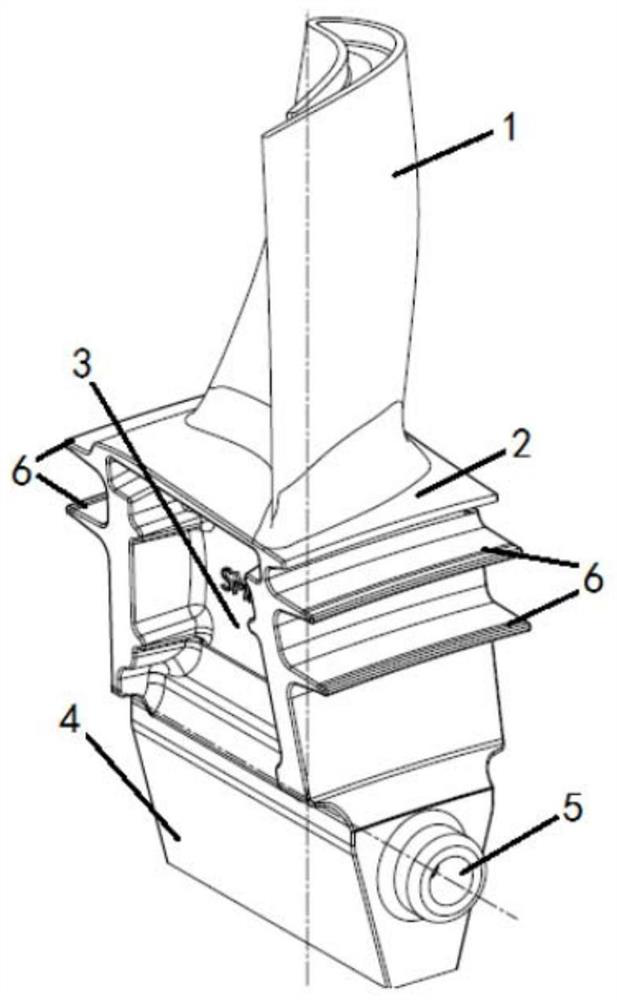

[0036] Single crystal turbine blades such as image 3 As shown, it specifically includes blade body 1, inner side of mounting plate 2, extension section 3, tenon 4, thimble boss 5 and sealing plate 6.

[0037] The precision casting method is to manufacture a set of precision casting modules, such as Figure 4 , the investment casting module includes a formwork and a chassis 12 arranged in sequence from top to bottom, the formwork includes a sprue cup 7, a subgroup tree structure 8, a gating system 9, a pillar 13 and an upper sprue 15, and the sprue cup 7. The upper runner 15 and the gating system 9 can be designed according to the specific size, weight and geometric shape of the blade. The subgroup tree structure 8 consists of three parts: the blade 14, the single crystal movable blade selector 10, and the seed crystal segment 11. In the wax module combination stage, the seed crystal segment 11 is directly inserted into the positioni...

Embodiment 2

[0055] Casting technical scheme design:

[0056] Single crystal turbine blades such as image 3 As shown, it specifically includes blade body 1, inner side of mounting plate 2, extension section 3, tenon 4, thimble boss 5 and sealing plate 6.

[0057] The precision casting method is to manufacture a set of precision casting modules, which include a mold shell and a chassis 12 arranged in sequence from top to bottom, and the mold shell includes a sprue cup 7, a subgroup tree structure 8, and a gating system 9 , pillar 13 and upper runner 15, sprue cup 7, upper runner 15 and gating system 9 can be designed according to the specific size, weight and geometric shape of the blade. The subgroup tree structure 8 consists of three parts: the blade 14, the single crystal movable blade selector 10, and the seed crystal segment 11. In the wax module combination stage, the seed crystal segment 11 is directly inserted into the positioning groove of the single crystal movable blade selecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com