A Fischer-Tropsch synthetic oil production api Ⅲ + Hydrogenation method of base oil

A technology of Fischer-Tropsch synthetic oil and lubricating base oil, which is applied in the direction of hydrocarbon oil treatment products, hydroprocessing process, and hydrocarbon oil treatment, which can solve the problems of Fischer-Tropsch synthetic oil, etc., and achieve increased processing capacity and cracking Good effect, reduce load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

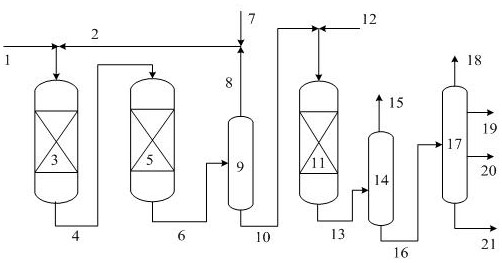

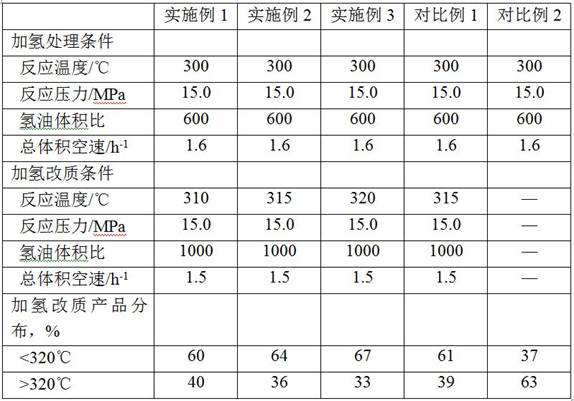

[0040] like figure 1 As shown in the process, the existing commercial catalysts are selected, the hydrotreating catalyst FF-26 is used in the hydrotreating reaction zone, the hydro-upgrading catalyst FC-14 is used in the hydro-upgrading reaction zone, and the iso-iso-dewaxing reaction zone is used in the isomerization and dewaxing reaction zone. Dewaxing catalyst FIW-12. The hydrogenation process conditions and results are shown in Table 2-3.

Embodiment 2

[0042] Process such as figure 1 shown. Adjust the process parameters, adjust the hydrogenation reforming conversion rate, and see Table 2-3 for the hydrogenation process conditions and results.

Embodiment 3

[0044] Process such as figure 1 shown. Adjust the process parameters, adjust the hydrogenation reforming conversion rate, and see Table 2-3 for the hydrogenation process conditions and results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com