Method for producing lubricating oil basic oil from hydrogenated tail oil

A technology of lubricating base oil and hydrocracking tail oil, which is applied in the direction of lubricating composition, hydrotreating process, base material, etc., can solve the problems of complex production process and high cost, and achieve improved activity, low investment and good synergy catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

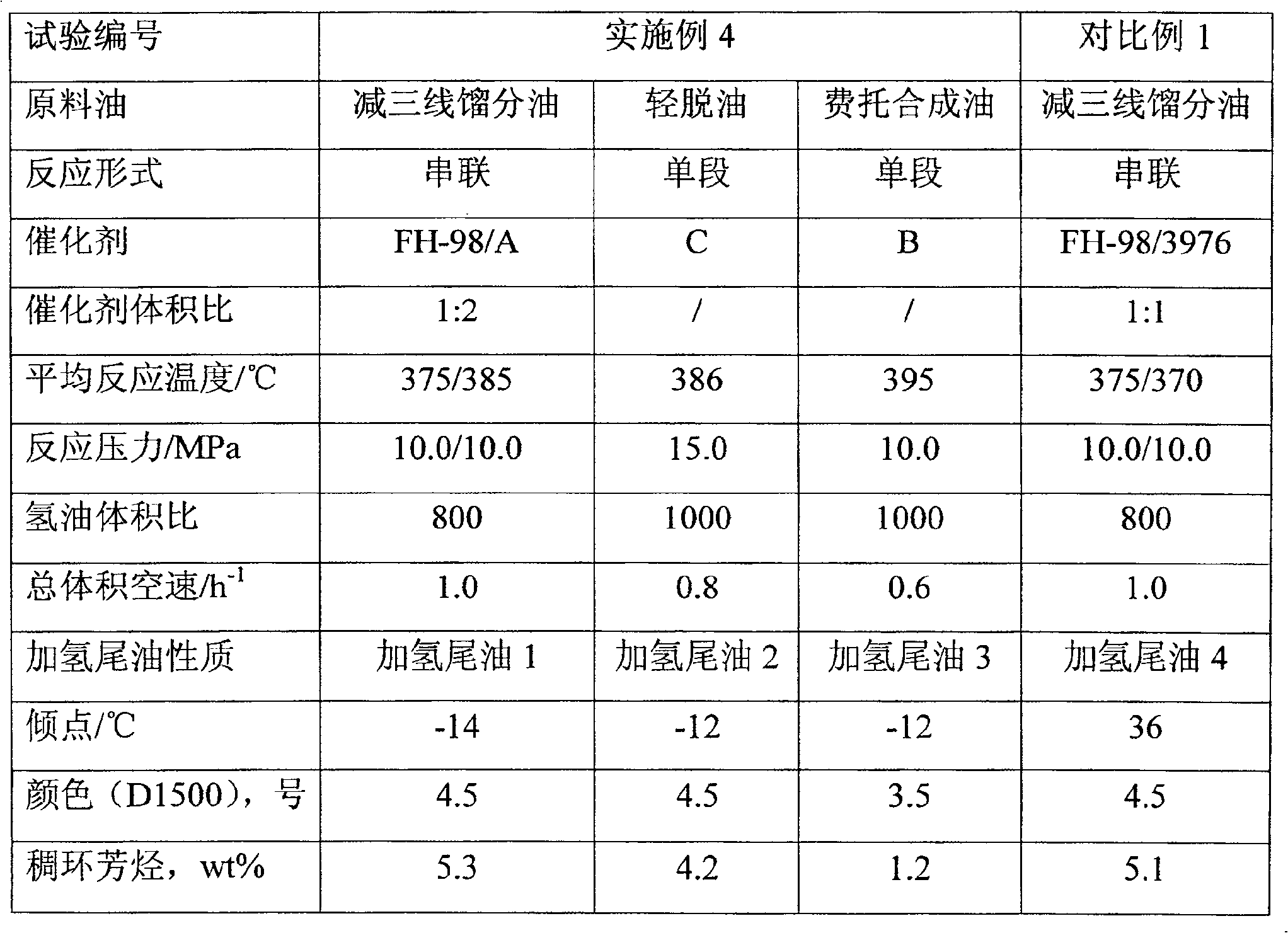

Examples

Embodiment 1

[0027] 227.1 g of amorphous silica-alumina (SiO 2 The content is 45wt%, the pore volume is 0.75ml / g, and the specific surface area is 390m 2 / g), 18.8 grams of modified β molecular sieves, 65.8 grams of macroporous alumina (the pore volume is 1.0ml / g, and the specific surface area is 460m 2 / g) into the roller compactor, mixed for 30 minutes, then add 288.5 grams of binder (with a pore volume of 0.4ml / g and a specific surface area of 280m 2 / g of small-pore alumina 107.1g, HNO 3 Molar ratio to alumina is 0.3), rolling for 30 minutes, then add 60 ml of water, continue rolling until the paste can be extruded, extruded, and dried at 110°C for 6 hours. The dried strips were heated up to 580° C. and calcined for 4 hours to obtain the carrier. The carrier was impregnated with an impregnating solution containing tungsten and nickel for 2 hours at room temperature, dried at 120°C for 6 hours, and calcined at a programmed temperature of 480°C for 4 hours to obtain a hydrocracking ...

Embodiment 2

[0030] 252.8 grams of amorphous silicon aluminum (SiO 2 The content is 65wt%, the pore volume is 0.58ml / g, and the specific surface area is 340m 2 / g), 9.4 grams of modified β molecular sieves, 41.1 grams of macroporous alumina (pore volume is 0.75ml / g, specific surface area is 360m 2 / g) put into the roller compactor and mix for 20 minutes, then add 323.1 grams of binder (with a pore volume of 0.45ml / g and a specific surface area of 300m 2 / g small pore alumina 120.0g, HPO 3 The molar ratio to alumina is 0.2), continue rolling for 40 minutes, then add 55 ml of water, roll until the paste can be extruded, extrude, and dry the extruded strips at 140°C for 3 hours. The drying strip was heated to 530° C. and calcined for 5 hours to obtain the carrier. The carrier was impregnated with an impregnation solution containing tungsten and nickel at room temperature for 4 hours, dried at 130°C for 3 hours, and then calcined at 460°C for 5 hours to obtain catalyst B. The physical an...

Embodiment 3

[0033] 201.4 g of amorphous silica-alumina (SiO 2 The content is 30wt%, the pore volume is 0.89ml / g, and the specific surface area is 460m 2 / g), 40.5 grams of modified β molecular sieves, 82.8 grams of macroporous alumina (same as Example 1) were put into the roller compactor and mixed for 40 minutes, then added 265.4 grams of binding agent (same as Example 1), and continued Roll for 25 minutes, then add 30 milliliters of water, roll to extrude paste, extrude, and extrude at 130°C for 4 hours. The drying strip was heated up to 680° C. and calcined for 2.5 hours to obtain the carrier. The carrier was impregnated with an impregnation solution containing tungsten and nickel at room temperature for 8 hours, dried at 130°C for 4 hours, and calcined at 530°C for 3 hours to obtain catalyst C. The physical and chemical properties are shown in Table 1.

[0034] The properties of the modified β molecular sieve are: molecular sieve SiO 2 / Al 2 o 3 Weight ratio 85, specific surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com