A kind of combined hydrotreating method

A technology of hydroprocessing and hydrogenation reaction, which is applied in the fields of combined hydroprocessing of diesel oil hydroprocessing, wax oil hydroprocessing and gasoline hydroprocessing, and can solve the problems of unobvious necessity, high operating cost, and total investment cost. High-level problems, to avoid coking of the furnace tube, meet the reaction requirements, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

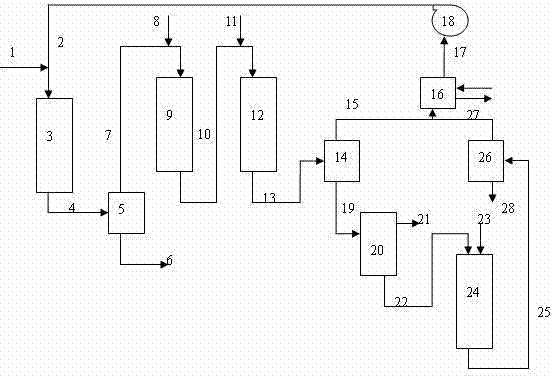

[0040] The technical process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] Such as figure 1 As shown, the wax oil raw material 1 is mixed with hydrogen 2 and enters the first reaction zone 3 to obtain a hydrotreated stream 4 with low content of impurities such as sulfur and nitrogen. The hydrotreated stream 4 is separated in the hot high-pressure separator 5, and the obtained hydrogenated wax oil 6 is directly discharged from the device, and the separated gas phase (including hydrogen and light distillate oil) 7 is mixed with coker gasoline raw material 8, and then enters the second In the second reaction zone 9, the hydrogenation reaction is carried out in the presence of the gasoline hydrofinishing catalyst, and the reaction effluent 10 is mixed with the diesel feedstock 11 and enters the third reaction zone 12, where the hydrogenation reaction is carried out in the presence of the diesel hydrofinishing cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com