Material modification device, system and method based on dielectric barrier discharge plasma

A dielectric barrier discharge and plasma technology, which is applied in the field of plasma material modification devices, can solve the problems of limited processing uniformity, limited processing range, and inability to change the discharge gas atmosphere, so as to reduce randomness and dispersion, improve Material performance, effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

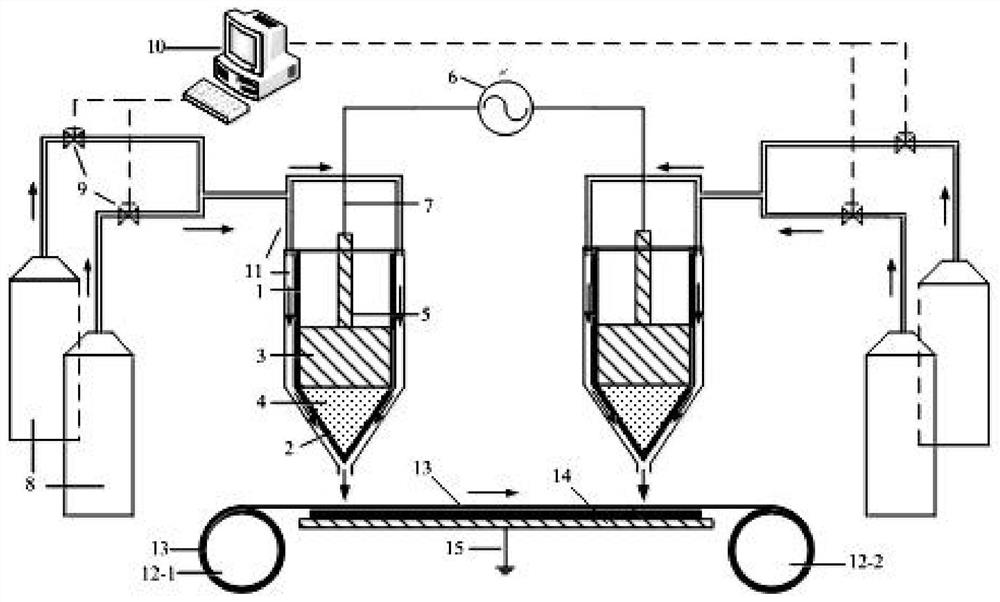

[0040] The technical solutions of the present disclosure will be described in further detail below in conjunction with specific embodiments and accompanying drawings. The embodiments are only partial embodiments and are not intended to limit the present disclosure.

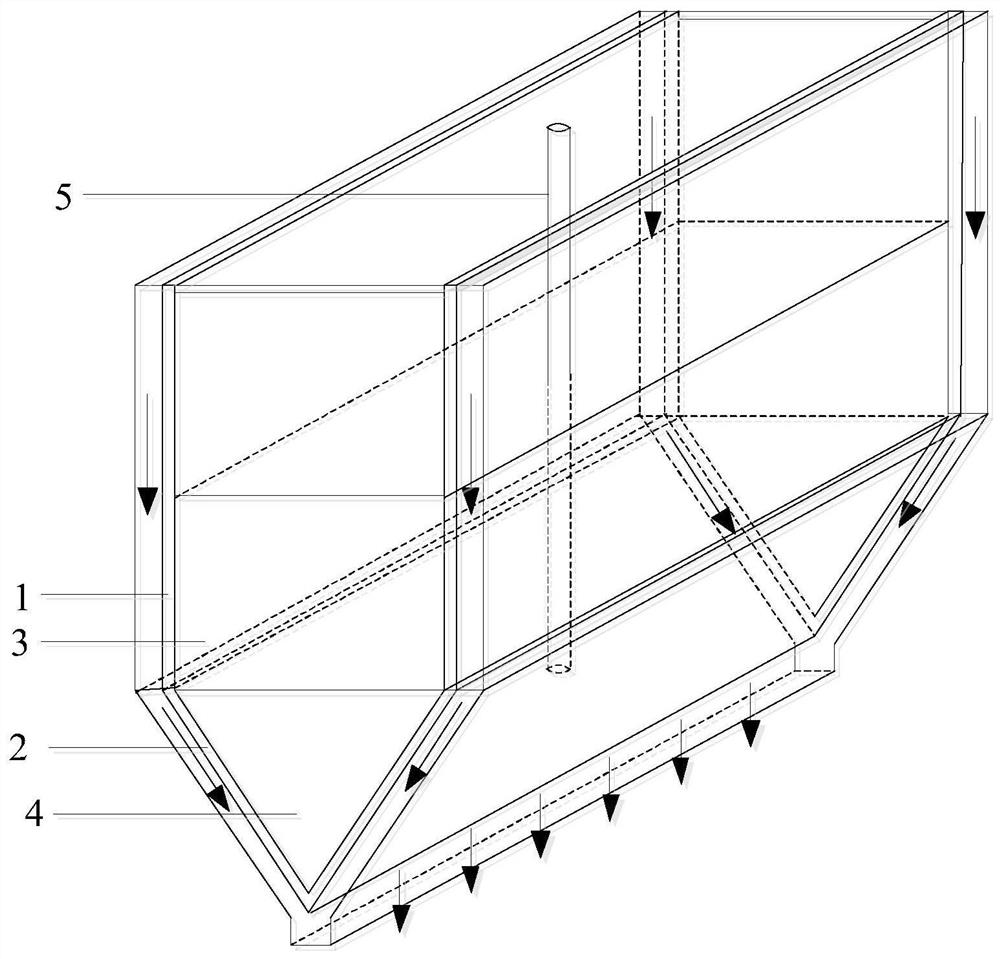

[0041] In one embodiment, such as figure 1 As shown, a material modification device based on dielectric barrier discharge plasma includes: a device body, the device body includes an upper part 1 of the device body and a lower part 2 of the device body; wherein,

[0042] The upper part 1 of the device main body is a cuboid;

[0043] The lower part 2 of the main body of the device is a cone, which is used to generate a discharge with a high degree of uniformity;

[0044] A copper plate 3 is provided at the connection between the upper part 1 of the device main body and the lower part 2 of the device main body;

[0045] The central position of the copper plate 3 is provided with an inner screw hole, and a copper sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com