A kind of ammonia removal agent for rubber and plastic foam products and preparation method thereof

A technology of rubber and plastic foaming and ammonia removal agent, which is applied in the field of rubber and plastic processing. It can solve the problems of expensive OBSH foaming agent, residual formamide, and inability to compare foamed products, and achieves the effect of wide application and convenient addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

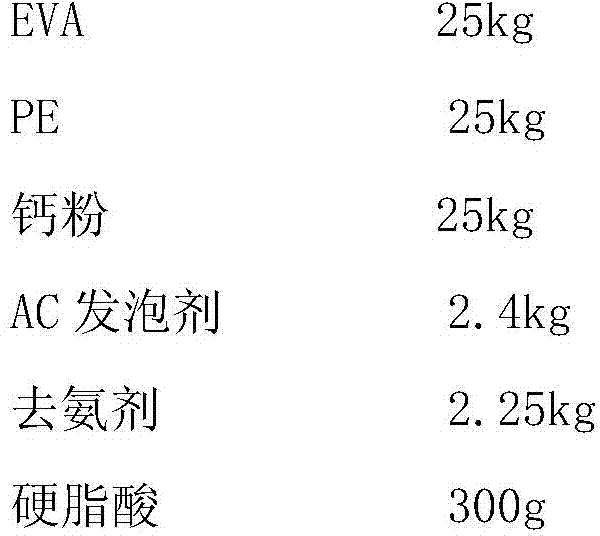

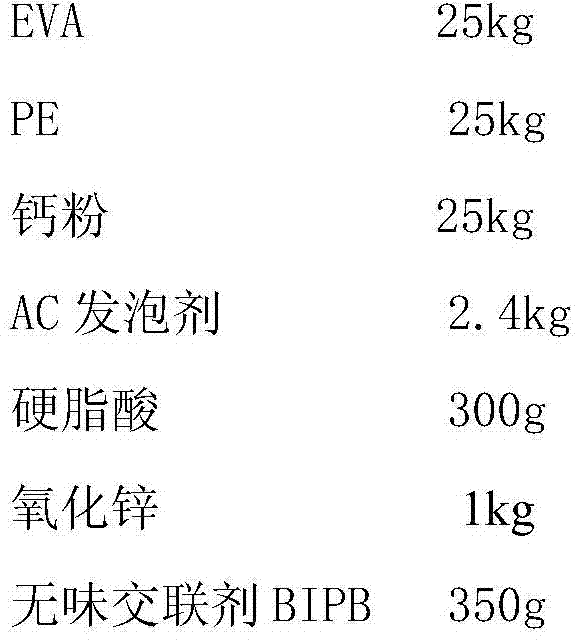

Image

Examples

Embodiment 1

[0026] Embodiment 1 The preparation of ammonia removal agent

[0027] (1) Add 1kg sodium stearate, 1kg stearic acid and 35kg white oil into the container and stir;

[0028] (2) Add 60kg of anhydrous aluminum sulfate in the stirring process until it dissolves into a uniform paste to obtain the ammonia removal agent, which is then packaged.

Embodiment 2

[0029] Embodiment 2 Preparation of ammonia removal agent

[0030] (1) Add 1.5kg sodium stearate, 1kg stearic acid and 37kg white oil into the container, stir;

[0031] (2) Add 65 kg of anhydrous aluminum sulfate in the stirring process until it dissolves into a uniform paste to obtain the ammonia removal agent and pack it separately.

Embodiment 3

[0032] Embodiment 3 The preparation of ammonia removal agent predispersed masterbatch

[0033] (1) Add 1kg sodium stearate, 1kg stearic acid and 35kg white oil into the container and stir;

[0034] (2) add 60kg of anhydrous aluminum sulfate again in stirring process, until dissolving becomes uniform paste, obtains ammonia agent;

[0035] (3) Mix the obtained ammonia removal agent with EVA at a mass ratio of 3:1, put them into an internal mixer and banbury until both are melted and evenly dispersed together;

[0036] (4) Put the mixed dough into a plastic granulator for granulation, and cool to obtain the pre-dispersed masterbatch of ammonia removal agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com