Preparation method for ultrathin boron nitride nanosheets and dispersion liquid thereof

A technology of boron nitride and nanosheets, which is applied in the field of nanomaterials, can solve problems affecting the growth of hexagonal boron nitride crystals, strong corrosiveness of chemicals, and difficult transfer, and achieve shortened preparation time, low cost, and operating costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

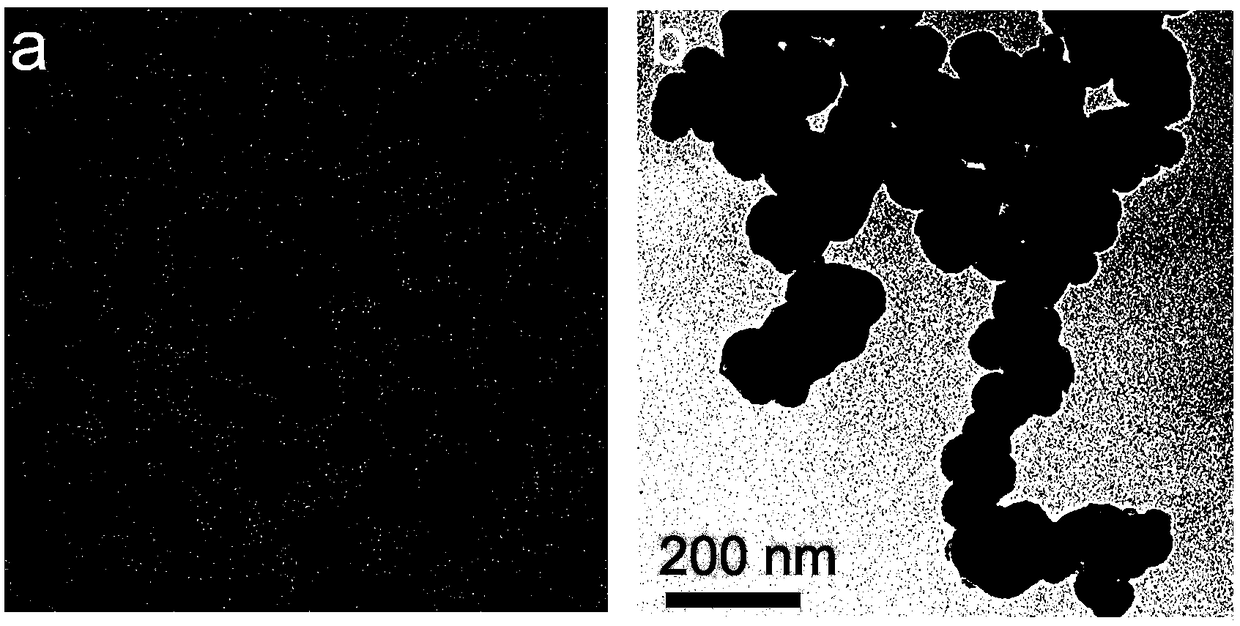

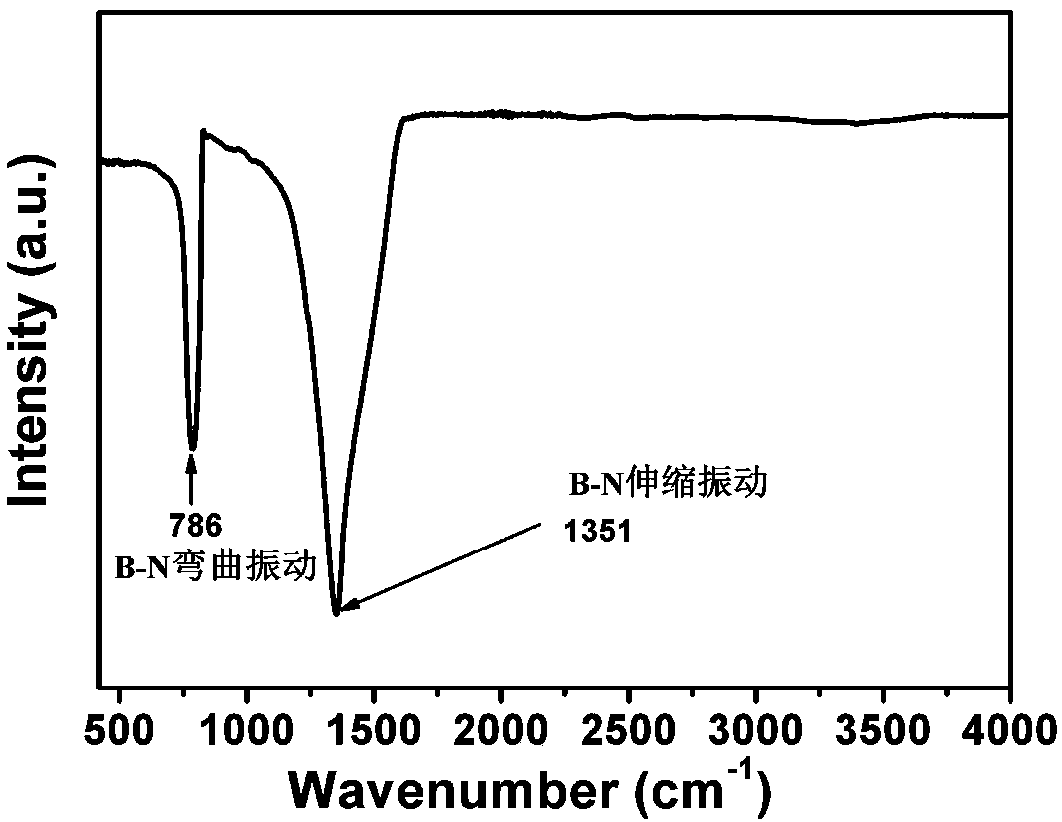

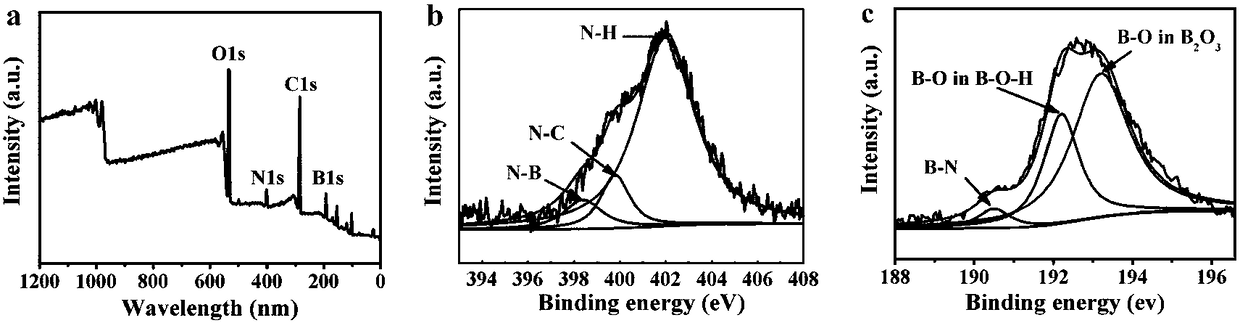

[0031] (1) Preparation of boron nitride quantum dots

[0032] Add 3g of boric acid powder into a polytetrafluoroethylene stainless steel autoclave, then add 60mL of concentrated ammonia water in a fume hood, after ultrasonication for 30min, put it in a blast drying oven and heat it to 200°C, and react for 24h to prepare a nitriding compound with simultaneous modification of amino and hydroxyl groups. Boron quantum dot (BNQD) solution;

[0033] (2) Preparation of boron nitride crystal

[0034] After the boron nitride quantum dot solution is cooled, pour it into a 100mL glass bottle and keep it sealed for a week. It can be observed that colorless and transparent crystals appear at the bottom of the vial. After ordinary filtration, wash with ultrapure water for 3 times, put Boron nitride crystals were prepared after drying in an oven at 70°C for 2.5 hours;

[0035] (3) Preparation of Ultrathin Boron Nitride Nanosheet Dispersion

[0036] Add boron nitride crystals into ultrapur...

Embodiment 2

[0040] (1) Preparation of boron nitride quantum dots

[0041] Add 5g of boric acid powder into a polytetrafluoroethylene stainless steel autoclave, then add 65mL of concentrated ammonia water in a fume hood, after ultrasonication for 30 minutes, put it in a blast drying oven and heat it to 180°C, and react for 24 hours to prepare a nitriding compound with simultaneous modification of amino and hydroxyl groups. Boron quantum dot (BNQD) solution;

[0042] (2) Preparation of boron nitride crystal

[0043] After the boron nitride quantum dot solution is cooled, pour it into a 100mL glass bottle and keep it sealed for a week. It can be observed that colorless and transparent crystals appear at the bottom of the vial. After ordinary filtration, wash with ultrapure water for 3 times, put Boron nitride crystals were prepared after being dried in an oven at 80°C for 3 hours;

[0044] (3) Preparation of Ultrathin Boron Nitride Nanosheet Dispersion

[0045] Add boron nitride crystals ...

Embodiment 3

[0048] (1) Preparation of boron nitride quantum dots

[0049] Add 4g of boric acid powder into a polytetrafluoroethylene stainless steel autoclave, then add 55mL of concentrated ammonia water in the fume hood, after ultrasonication for 30 minutes, put it in a blast drying oven and heat it to 160°C, and react for 24 hours to prepare a nitriding compound with simultaneous modification of amino and hydroxyl groups. Boron quantum dot (BNQD) solution;

[0050] (2) Preparation of boron nitride crystal

[0051] After the boron nitride quantum dot solution is cooled, pour it into a 100mL glass bottle and keep it sealed for a week. It can be observed that colorless and transparent crystals appear at the bottom of the vial. After ordinary filtration, wash with ultrapure water for 3 times, put Boron nitride crystals were prepared after drying in an oven at 65°C for 2.5 hours;

[0052] (3) Preparation of Ultrathin Boron Nitride Nanosheet Dispersion

[0053] Add boron nitride crystals i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com