Ferriporphyrin/bismuth tungstate composite photocatalytic material and preparation method thereof

A composite photocatalysis and iron porphyrin technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem that iron porphyrin is difficult to separate, recover and reuse. , affecting the properties of synthetic materials, easily destroying the crystal form of bismuth tungstate, etc., to achieve the effect of enhancing recyclability, ensuring sufficient contact, and being easy to recycle and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

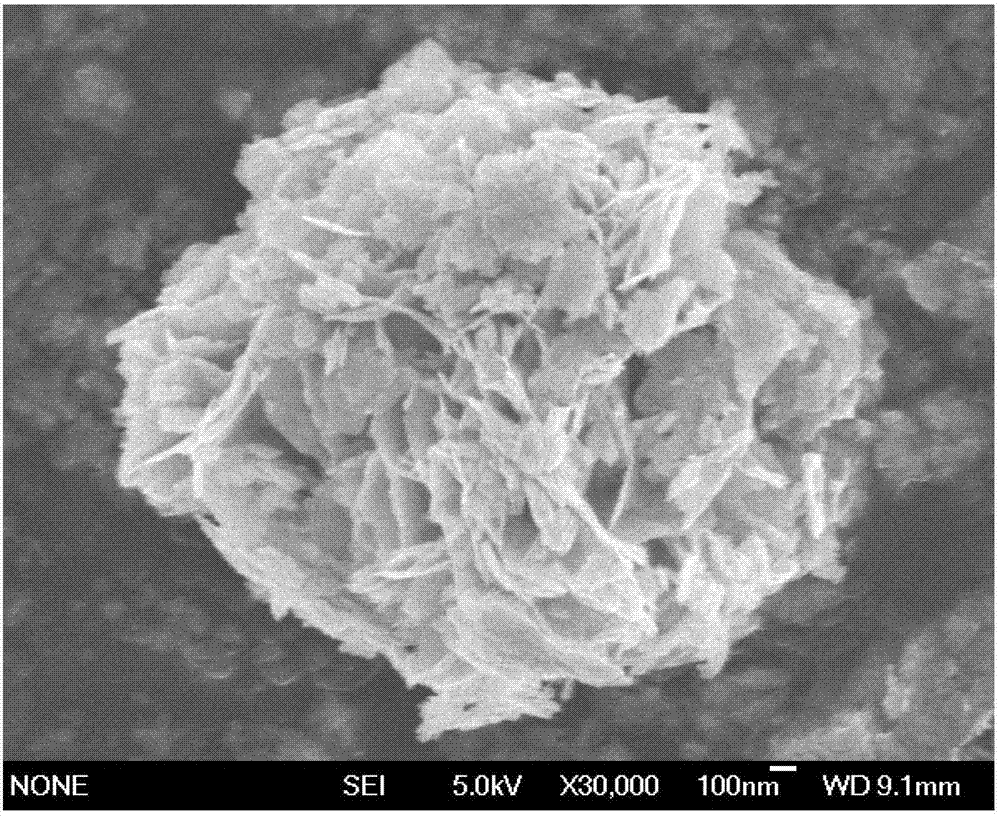

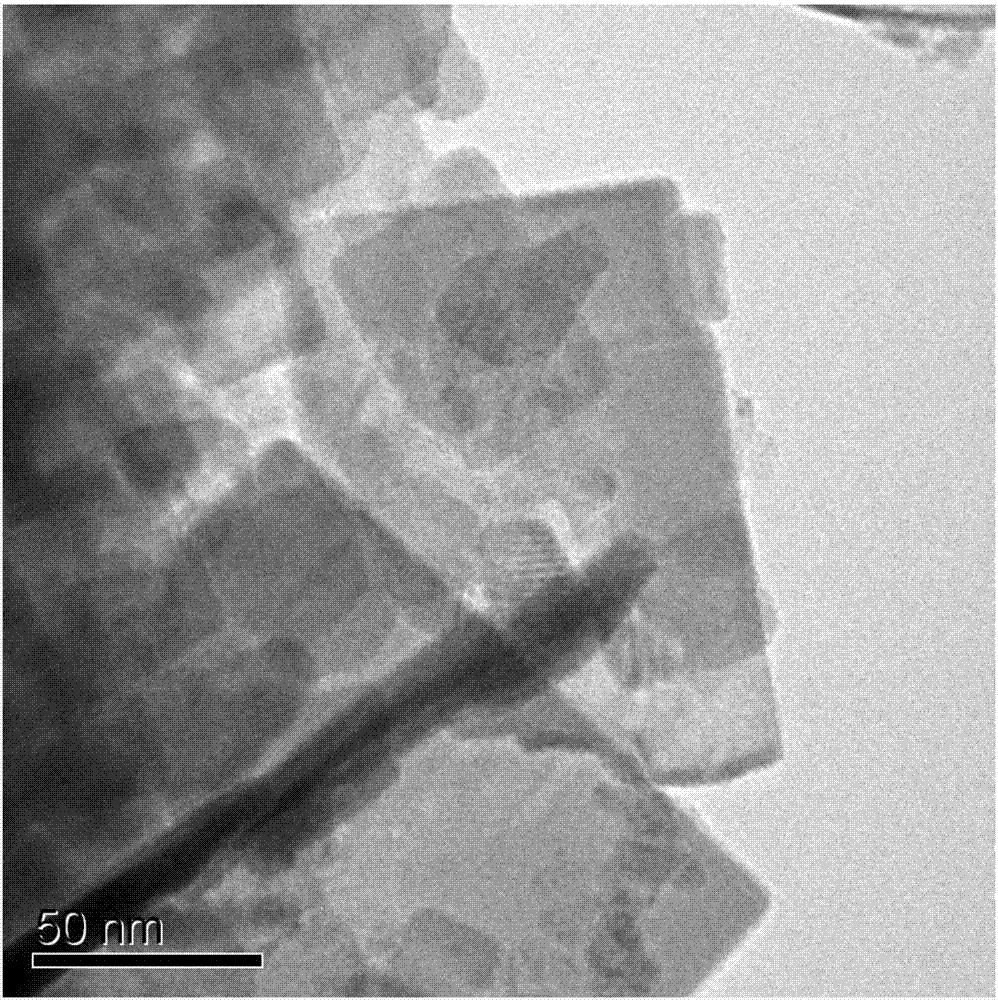

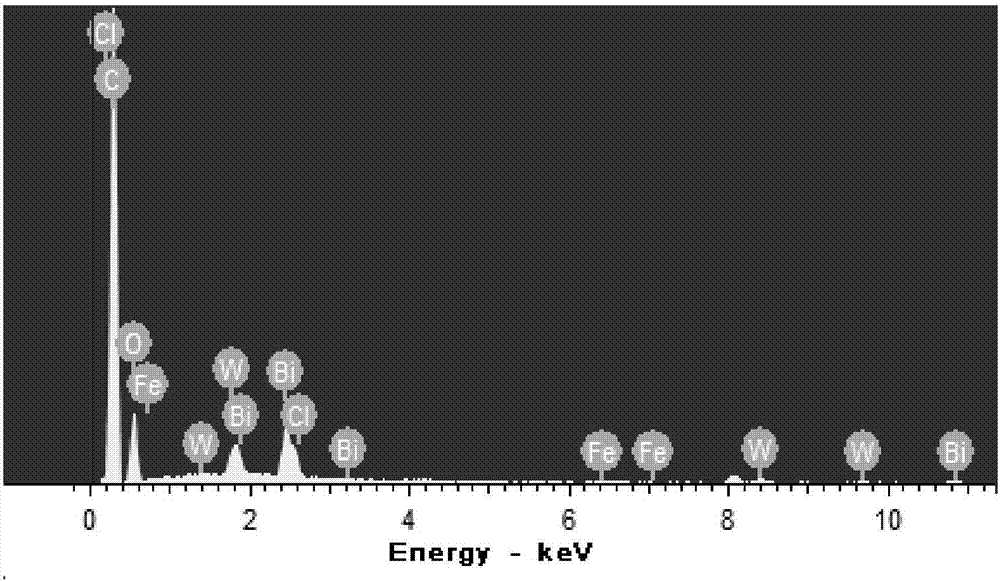

[0039] An iron porphyrin / bismuth tungstate composite photocatalytic material comprises iron porphyrin and bismuth tungstate, wherein the iron porphyrin is supported on the bismuth tungstate.

[0040] In this embodiment, the mass ratio of iron porphyrin to bismuth tungstate in the iron porphyrin / bismuth tungstate composite photocatalytic material is 2:10.

[0041] In this embodiment, the particle size of the iron porphyrin / bismuth tungstate composite photocatalytic material is 1 μm˜3 μm.

[0042] A kind of preparation method of iron porphyrin / bismuth tungstate composite photocatalytic material of above-mentioned present embodiment, comprises the following steps:

[0043] (1) Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O, respectively dissolved in 1mol / L nitric acid solution and sodium hydroxide solution to obtain bismuth nitrate solution and sodium tungstate solution respectively, wherein in the bismuth nitrate solution Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.05...

Embodiment 2

[0050] An iron porphyrin / bismuth tungstate composite photocatalytic material comprises iron porphyrin and bismuth tungstate, wherein the iron porphyrin is supported on the bismuth tungstate.

[0051] In this embodiment, the mass ratio of iron porphyrin to bismuth tungstate in the iron porphyrin / bismuth tungstate composite photocatalytic material is 1:10.

[0052] In this embodiment, the particle size of the iron porphyrin / bismuth tungstate composite photocatalytic material is 1 μm˜3 μm.

[0053] A kind of preparation method of iron porphyrin / bismuth tungstate composite photocatalytic material of above-mentioned present embodiment, comprises the following steps:

[0054] (1) Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O, respectively dissolved in 1mol / L nitric acid solution and sodium hydroxide solution to obtain bismuth nitrate solution and sodium tungstate solution respectively, wherein in the bismuth nitrate solution Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.05...

Embodiment 3

[0075] An iron porphyrin / bismuth tungstate composite photocatalytic material comprises iron porphyrin and bismuth tungstate, wherein the iron porphyrin is supported on the bismuth tungstate.

[0076] In this embodiment, the mass ratio of iron porphyrin to bismuth tungstate in the iron porphyrin / bismuth tungstate composite photocatalytic material is 1:10.

[0077] In this embodiment, the particle size of the iron porphyrin / bismuth tungstate composite photocatalytic material is 1 μm˜3 μm.

[0078] A kind of preparation method of iron porphyrin / bismuth tungstate composite photocatalytic material of above-mentioned present embodiment, comprises the following steps:

[0079] (1) Weigh Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 O, respectively dissolved in 1mol / L nitric acid solution and sodium hydroxide solution to obtain bismuth nitrate solution and sodium tungstate solution respectively, wherein in the bismuth nitrate solution Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.05...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com