Efficient environment-friendly plant fertilization apparatus

An environmentally friendly and efficient technology, applied in fertilization devices, manure treatment, liquid fertilizer distribution, etc., can solve the problems of complicated use and increase the time-consuming of spraying, and achieve the effect of convenient operation, improved convenience, and improved mixing uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

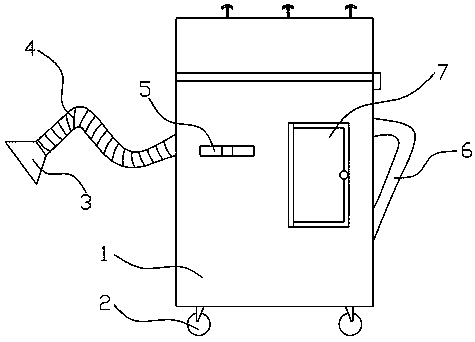

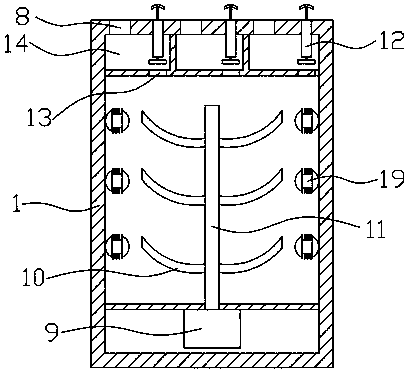

[0023] Such as Figure 1~3 As shown, the efficient and environmentally friendly plant fertilization equipment includes a box body 1, a nozzle 3 connected to the left side of the box body 1, a handle 6 connected to the right side of the box body 1, and a stirring element arranged inside the box body 1. The box body 1. A fixed ball 19 is connected to the surface of the inner wall. The box body 1 is used to realize fertilizer mixing and store mixed water. After raising the handle 6, one side of the nozzle 3 is lowered to form a height difference, so that the mixed water is sprayed from the nozzle 3 to realize Fertilizer spraying and irrigation, the overall size of the equipment is small, light in weight, easy to carry and spray, and reduces the need for equipment handling, which can improve the efficiency of fertilizer spraying. The equipment is made of environmentally friendly materials, which will not cause harm to plants when used, and can be recycled after being discarded. us...

Embodiment 2

[0034] This embodiment is a further optimization scheme on the basis of embodiment 1: as Figure 4 As shown, the fixed ball 19 includes a symmetrically arranged small hemispherical body 19a, a central column 19b is rollingly connected between the small hemispherical body 19a, and a brush 19c is connected to the upper and lower sides of the central column 19b, and the fixed ball 19 is arranged on the inner wall of the casing 1. During the stirring process of the stirring element, the circulating flow of water impacts the fixed ball 19, so that the central column 19b rotates between the small hemispheres 19a, and the brush 19c on the surface of the central column 19b generates a brushing force on the inner wall of the box body 1, so that The fertilizer adhering to the inner wall of the box body 1 re-enters the water body for mixing, which effectively improves the uniformity of fertilizer mixing, improves the effectiveness of fertilization, and promotes the increase in production ...

Embodiment 3

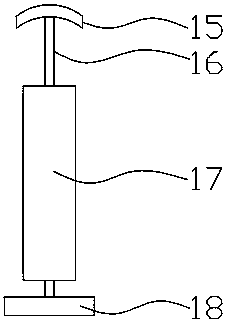

[0039] Such as Figure 1~5 As shown, the working principle of the present invention is: three fertilizer storage rooms 14 are preferably arranged inside the box body 1, and by pressing the pull ring 15, the pull rod 16 is lowered to the rubber plug 18 to block the water outlet 13, and the fertilizer 1 and fertilizer 2 Put the fertilizer 3 into the fertilizer storage room 14 from left to right, move the device to the plant area to be sprayed with fertilizer, move the leftmost pull ring 15 to open the water outlet 13 of the leftmost fertilizer storage room 14, and drain the water body Inject the water into the leftmost fertilizer storage room 14 from the water inlet 8, the water body washes the fertilizer placed in the leftmost fertilizer storage room 14, and the fertilizer is carried to the area to be stirred inside the box body 1, and the rubber plug is injected into the suitable water body. 18 is re-inserted into the water outlet 13 to prevent water from flowing out of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com