Enrichment method of coal micromaceral

A micro-component and enrichment technology, applied in grain processing and other directions, can solve the problems of easily destroying the molecular structure of coal, toxicity, and easy oxidation, and achieve the effect of simple operation, good guidance, and not easy to be oxidized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

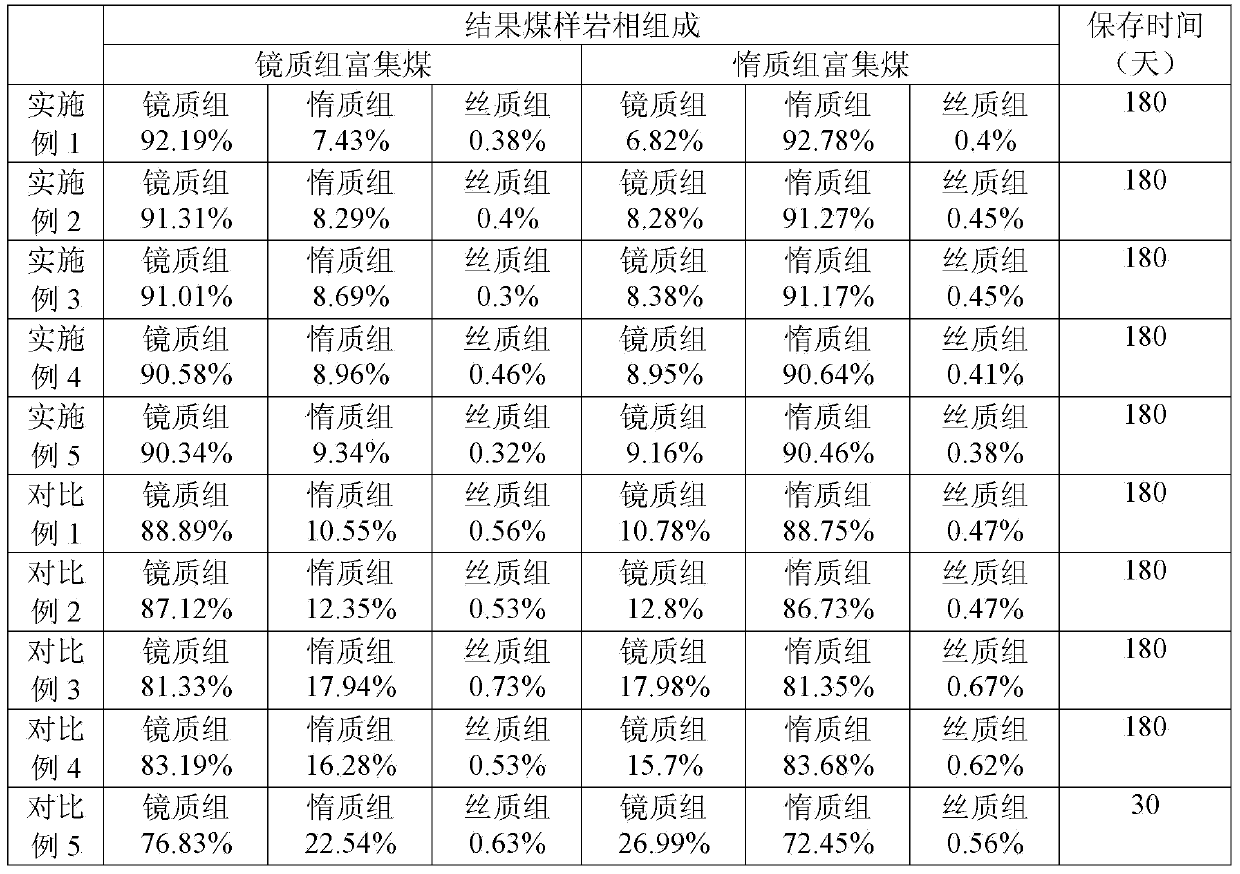

Examples

Embodiment approach

[0025] According to a preferred embodiment of the present invention, the enrichment method includes the following steps: S1, crushing the coal sample in one stage and separating it in one stage to obtain inert enrichment components smaller than the first particle size and larger than the first particle size vitrinite-enriched components; S2, secondary pulverization and secondary separation of vitrinite-enriched components to further obtain inert-enriched components smaller than the second particle size and vitrinite-enriched components larger than the second particle size Components; and S3, collecting the inertinite-enriched components obtained in steps S1 and S2 to obtain inertinite-enriched coal, and collecting the vitrinite-enriched components obtained in step S2 to obtain vitrinite-enriched coal . Preferably, in step S1, the coal sample is pulverized to a particle size of 25 mm or less, and the primary separation is performed; and in step S2, the vitrinite-enriched compon...

Embodiment 1

[0033] 1) Weigh the Shendong coal sample (the microcomponent content is: 52.3% of inertite coal, 42.5% of vitrinite coal, and 0.8% of silky coal). The coal samples were first separated by hand to obtain vitrinite-enriched samples (microcomponent contents: vitrinite 77.5%, inertinite 22.1%, silk 0.4%) and inertinite-enriched samples ( The content of microscopic components is: vitrinite group 75.3%, inertin group 23.7%, silk group 1.0%).

[0034] 2) The hand-selected vitrinite-enriched samples were pulverized by a first-stage ultra-fine airflow to a particle size below 25 mm, then subjected to a first-stage cyclone separation, and sieved with a sieve with a first particle size x of 1 mm to obtain particles Inertinite-enriched coal A with a particle size of less than 1 mm and vitrinite-enriched coal B with a particle size of 1-25 mm. Similarly, the inertinite-enriched samples are sequentially crushed by a primary ultrafine airflow to a particle size below 25 mm, then subjected t...

Embodiment 2

[0038] The operation steps are the same as in Example 1, except that in step 2), a sieve with a first particle size x of 0.8 mm is used for sieving, and in step 3, a sieve with a second particle size y of 0.008 mm is used for sieving, and finally The obtained high-purity vitrinite-enriched coal and high-purity inertinite-enriched coal are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com