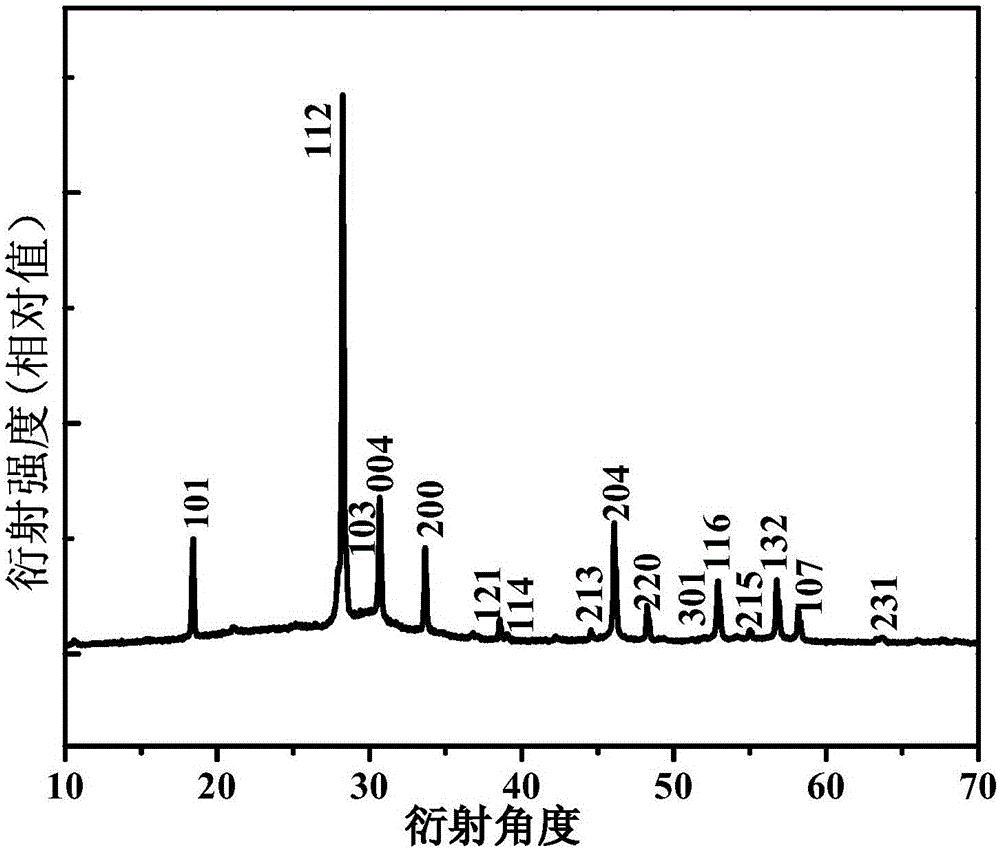

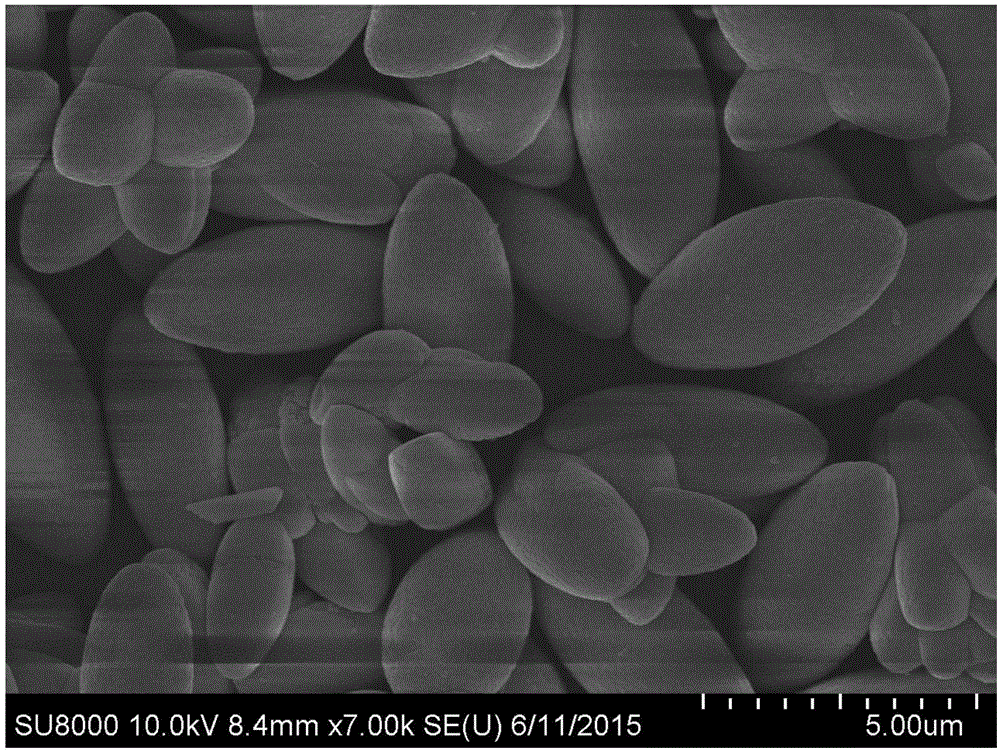

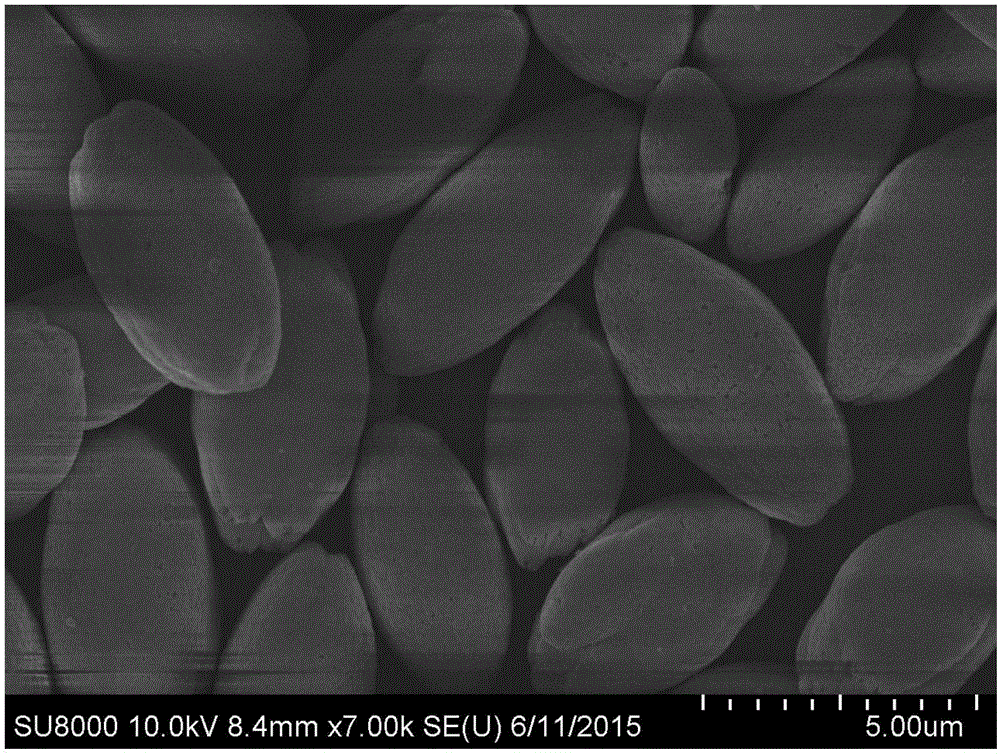

Method for fast preparation of olive-shaped lanthanum sodium tungstate

An olive-shaped sodium lanthanum tungstate and sodium tungstate technology, which is applied in chemical instruments and methods, tungsten compounds, nanotechnology for materials and surface science, etc., can solve the problems of unenvironmental protection, high reaction temperature and time-consuming production process. Long-term problems, to avoid the use of surfactants, simple process, easy to wash the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Using sodium tungstate and lanthanum nitrate as raw materials, and using sodium nitrate as an additive, it includes the following specific steps: (1) Preparation of solutions: prepare solution A and solution B respectively, solution A is a sodium tungstate solution with a concentration of 0.2mol / L, and the solution B is a mixture solution of lanthanum nitrate and sodium nitrate, wherein the concentration of lanthanum nitrate is 0.03mol / L, and the concentration of sodium nitrate is 8mol / L. The solvent used for preparing the solution is more suitable with deionized water, and distilled water is also available; (2) suspension Solution: under the condition of 5°C, quickly mix solution A and solution B according to the molar ratio of lanthanum nitrate and sodium tungstate 1:1.2 to prepare a suspension, adjust the pH of the system to 7 with sodium hydroxide and concentrated nitric acid, or use Ammonia and concentrated nitric acid to adjust the pH; (3) hydrothermal reaction: tr...

Embodiment 2

[0030] Using sodium tungstate and lanthanum nitrate as raw materials, and using sodium nitrate as an additive, it includes the following specific steps: (1) Preparation of solutions: prepare solution A and solution B respectively, solution A is a sodium tungstate solution with a concentration of 0.3mol / L, and the solution B is a mixture solution of lanthanum nitrate and sodium nitrate, wherein the concentration of lanthanum nitrate is 0.05mol / L, and the concentration of sodium nitrate is 12.5mol / L; (2) Suspension preparation: at 20°C, mix solution A and solution B Rapidly mix the lanthanum nitrate and sodium tungstate at a molar ratio of 1:1.5 to prepare a suspension, adjust the pH of the system to 8.5 with sodium hydroxide and concentrated nitric acid, or adjust the pH with ammonia water and concentrated nitric acid; (3) Hydrothermal reaction: Transfer the above suspension to a reaction kettle, react at 180°C for 12 hours, collect the resulting solid, wash with deionized water...

Embodiment 3

[0032]Using sodium tungstate and lanthanum nitrate as raw materials, and using sodium nitrate as an additive, it includes the following specific steps: (1) Preparation of solutions: prepare solution A and solution B respectively, solution A is sodium tungstate solution with a concentration of 0.4mol / L, solution B is a mixture solution of lanthanum nitrate and sodium nitrate, wherein the concentration of lanthanum nitrate is 0.07mol / L, and the concentration of sodium nitrate is 17mol / L; (2) Suspension preparation: under the condition of 35°C, prepare solution A and solution B according to The molar ratio of lanthanum nitrate and sodium tungstate is 1:1.8 and the suspension is quickly mixed, and the pH of the system is adjusted to 10 with sodium hydroxide and concentrated nitric acid, and the pH can also be adjusted with ammonia water and concentrated nitric acid; (3) Hydrothermal reaction: The above suspension was transferred to a reaction kettle and reacted at 200°C for 16 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com