Method for molding iron rod head of gold through vacuum weight casting

A golf ball and gravity casting technology, which is applied in the equipment, casting equipment, metal processing equipment, etc. for feeding molten metal into the mold, which can solve the problems affecting the tensile strength of golf iron head castings, insufficient casting, and the fluidity of molten metal. It can improve the molding rate and quality, reduce energy consumption, and avoid metal splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

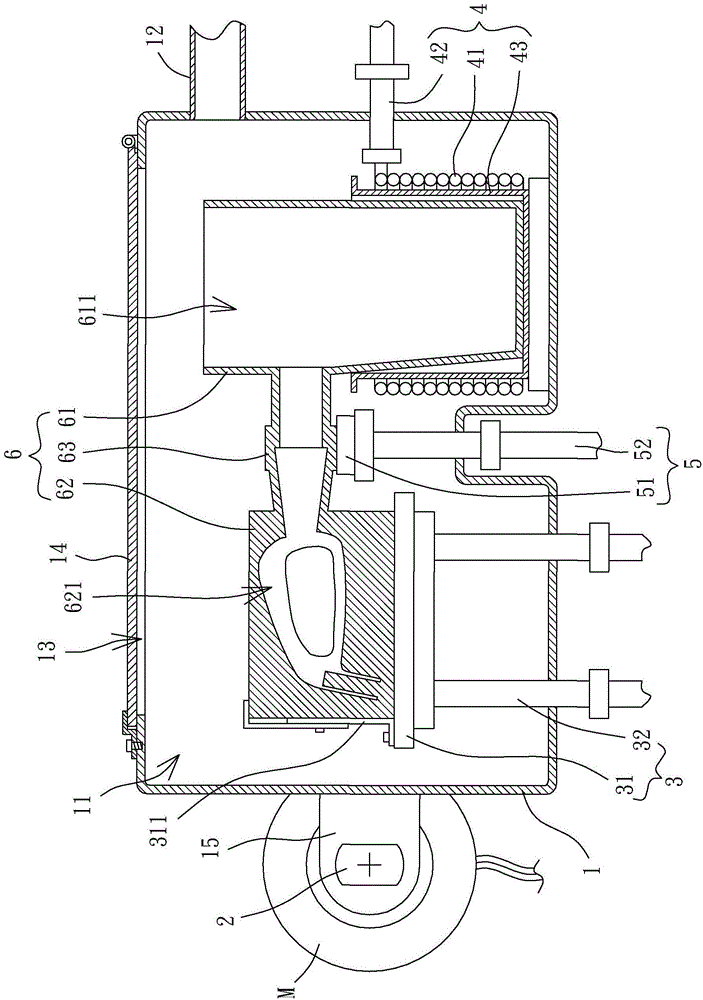

[0064] Please refer to figure 2 , which is a vacuum casting device used in conjunction with the method for vacuum gravity casting golf iron club heads of the present invention. Wherein, the vacuum casting device includes a vacuum furnace 1, a rotating shaft 2, a carrier 3, a heating module 4 and a support 5; In the vacuum furnace 1 , a shell mold 6 is placed for positioning, and the vacuum furnace 1 is connected to the rotating shaft 2 , so as to be turned over by the driving of the rotating shaft 2 .

[0065] More specifically, the interior of the vacuum furnace 1 has a chamber 11, the vacuum furnace 1 can be provided with an air duct 12, the air duct 12 communicates with the chamber 11, a vacuum controller (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com