Municipal road asphalt spreading pulling trolley

A technology for municipal roads and asphalt, applied in the field of municipal road asphalt laying trolleys, can solve the problems of uneven heating, influence of asphalt performance, uneven asphalt laying, etc., and achieve the effect of uniform asphalt laying and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

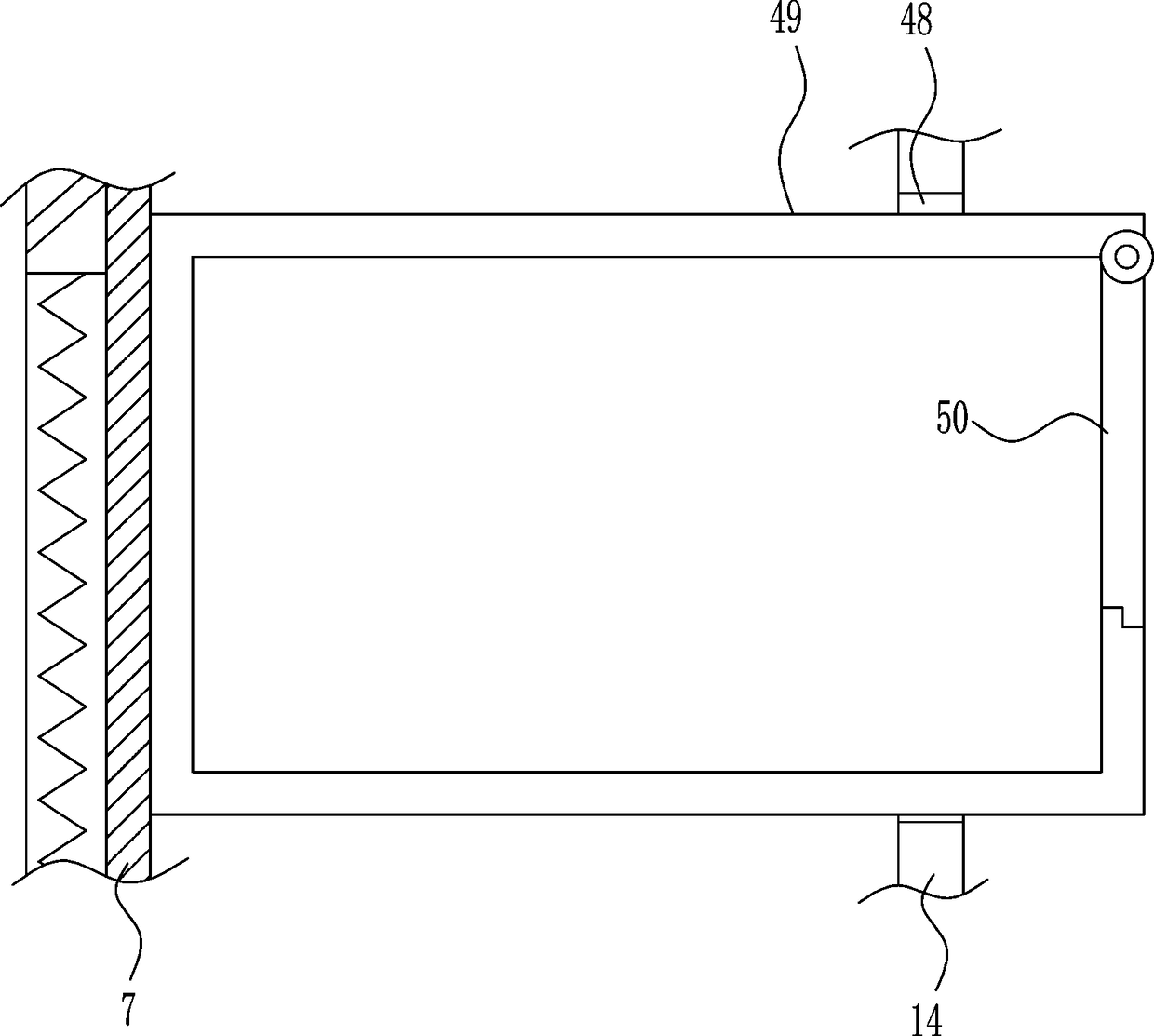

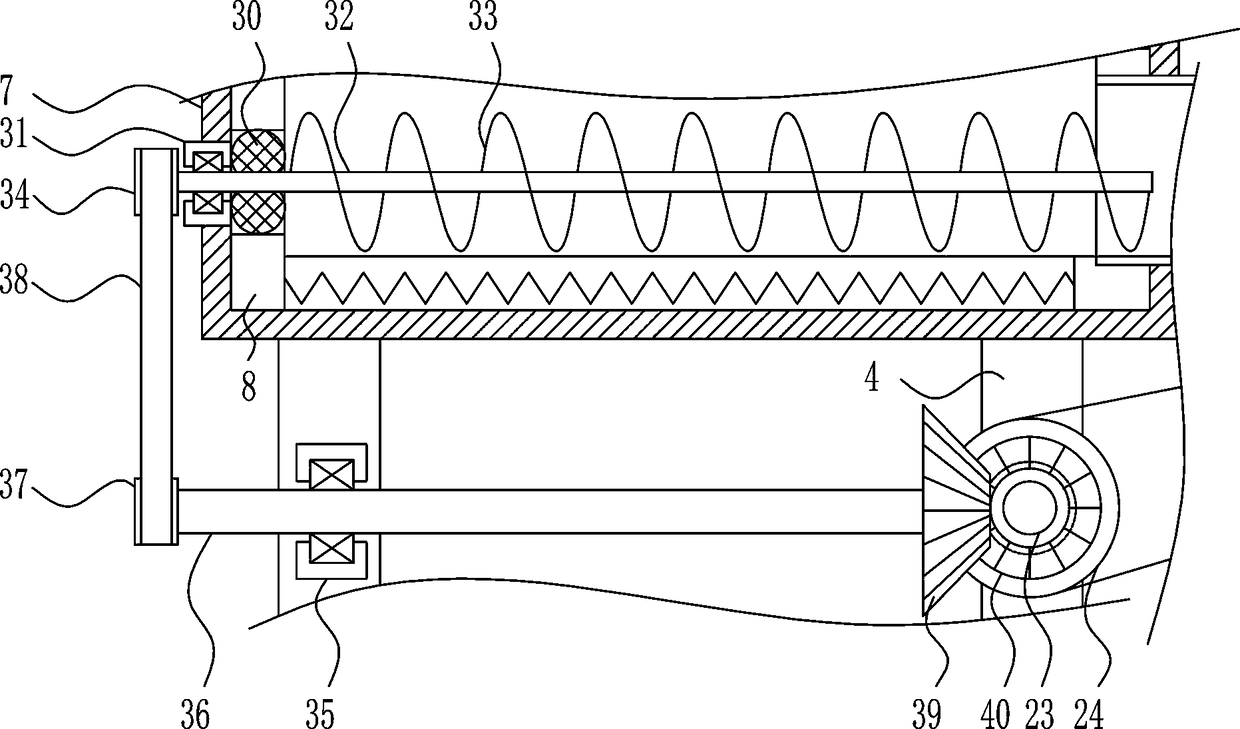

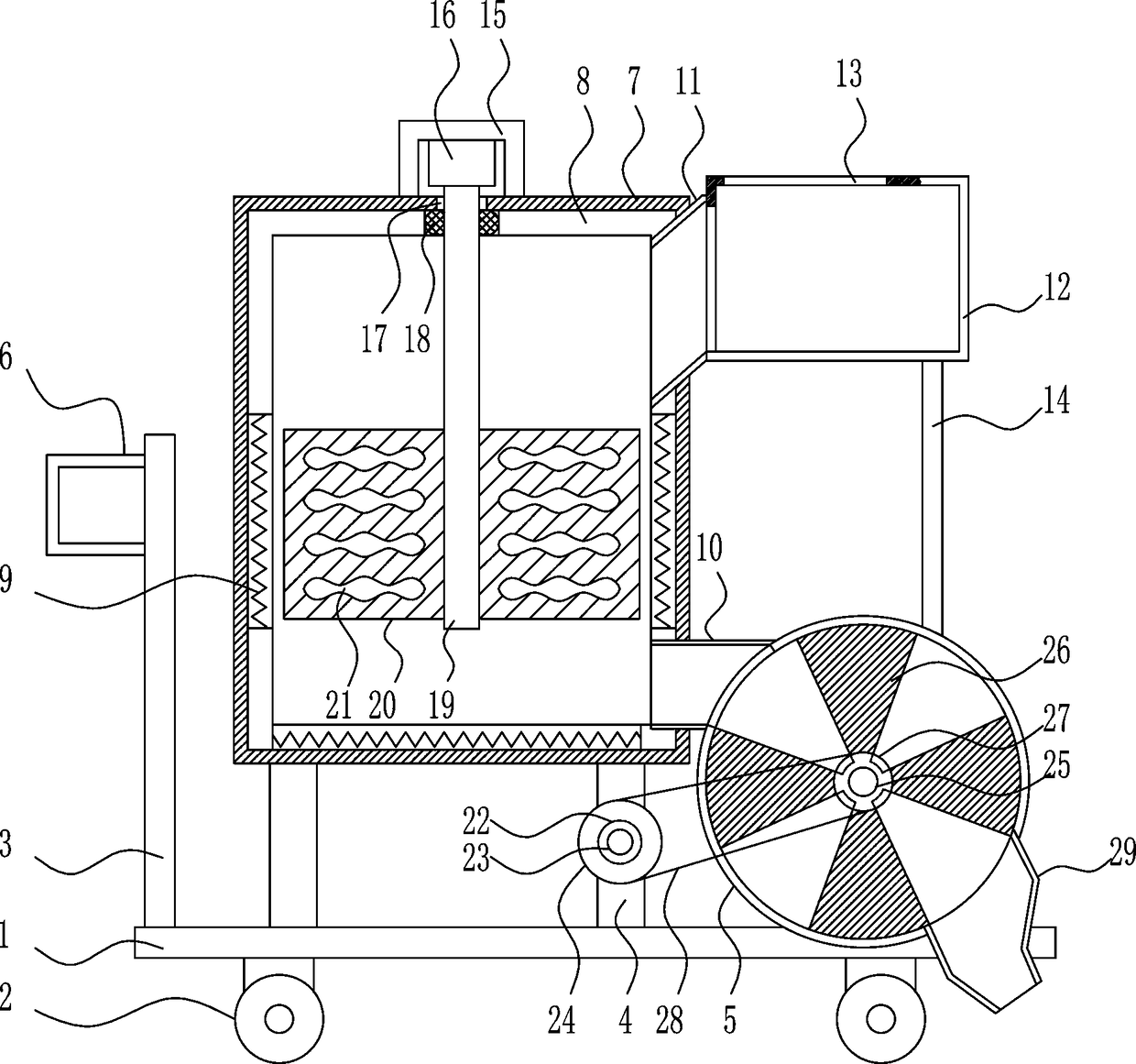

[0028] A municipal road asphalt laying cart, such as Figure 1-5As shown, it includes base plate 1, wheel 2, first bracket 3, second bracket 4, cylinder 5, handle 6, first shell 7, insulation layer 8, first heating wire 9, discharge pipe 10, feeding Pipe 11, feeding box 12, third bracket 14, frame 15, first motor 16, first sealing ring 18, first rotating shaft 19, stirring plate 20, second motor 22, second rotating shaft 23, first pulley 24 , the third rotating shaft 25, the fan-shaped rotating plate 26, the second pulley 27, the first flat belt 28 and the discharge hopper 29, the bottom plate 1 is provided with the wheels 2, and the top of the bottom plate 1 is provided with the first support 3 and the second from left to right. The bracket 4 and the cylinder 5, the upper left side of the first bracket 3 is provided with a handle 6, the top of the second bracket 4 is provided with a first shell 7, the inner wall of the first shell 7 is provided with an insulation layer 8, the...

Embodiment 2

[0030] A municipal road asphalt laying cart, such as Figure 1-5 As shown, it includes base plate 1, wheel 2, first bracket 3, second bracket 4, cylinder 5, handle 6, first shell 7, insulation layer 8, first heating wire 9, discharge pipe 10, feeding Pipe 11, feeding box 12, third bracket 14, frame 15, first motor 16, first sealing ring 18, first rotating shaft 19, stirring plate 20, second motor 22, second rotating shaft 23, first pulley 24 , the third rotating shaft 25, the fan-shaped rotating plate 26, the second pulley 27, the first flat belt 28 and the discharge hopper 29, the bottom plate 1 is provided with the wheels 2, and the top of the bottom plate 1 is provided with the first support 3 and the second from left to right. The bracket 4 and the cylinder 5, the upper left side of the first bracket 3 is provided with a handle 6, the top of the second bracket 4 is provided with a first shell 7, the inner wall of the first shell 7 is provided with an insulation layer 8, th...

Embodiment 3

[0033] A municipal road asphalt laying cart, such as Figure 1-5 As shown, it includes base plate 1, wheel 2, first bracket 3, second bracket 4, cylinder 5, handle 6, first shell 7, insulation layer 8, first heating wire 9, discharge pipe 10, feeding Pipe 11, feeding box 12, third bracket 14, frame 15, first motor 16, first sealing ring 18, first rotating shaft 19, stirring plate 20, second motor 22, second rotating shaft 23, first pulley 24 , the third rotating shaft 25, the fan-shaped rotating plate 26, the second pulley 27, the first flat belt 28 and the discharge hopper 29, the bottom plate 1 is provided with the wheels 2, and the top of the bottom plate 1 is provided with the first support 3 and the second from left to right. The bracket 4 and the cylinder 5, the upper left side of the first bracket 3 is provided with a handle 6, the top of the second bracket 4 is provided with a first shell 7, the inner wall of the first shell 7 is provided with an insulation layer 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com