Medicine crushing mechanism

A technology of crushing mechanism and medicinal materials, which is applied in the direction of grain processing, etc., can solve the problems of crushing head jamming, insufficient destruction, equipment damage, etc., and achieve the effect of eliminating crushing head jamming and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

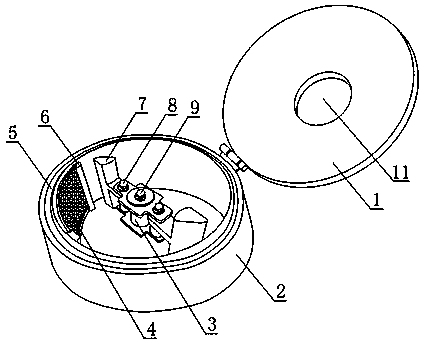

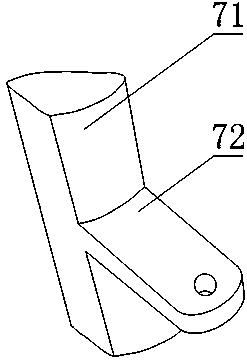

[0025] like figure 1 and figure 2 As shown, a medicinal material crushing mechanism includes a cylindrical cylinder body 2, and a rotating shaft 9 connected with a driving motor is also arranged in the cylinder body 2, and the rotating shaft 9 is located in the center of the cylinder body 2, and also includes a pin Seat 3, pin 8 and crushing head 7, described pin seat 3 is fixedly connected with rotating shaft 9, and pin hole is all provided with on pin seat 3 and crushing head 7, and described pin 8 all forms gap fit with two pin holes or with one of them The pin hole is interference fit, and the other pin hole is clearance fit, and the length direction of the pin 8 is parallel to the axial direction of the rotating shaft 9, and the distance between the free end of the crushing head 7 and the axis center of the rotating shaft 9 is not greater than that of the cylinder 2 radius.

[0026] In this embodiment, in order to facilitate the replacement of crushing heads 7 of diffe...

Embodiment 2

[0028] This embodiment is further improved on the basis of embodiment 1, as figure 1 and figure 2 As shown, in order to reduce the stress of the crushing head 7 in the working process of the present invention and obtain more application points of the present invention to the material, so as to facilitate the structure of the crushing head 7, the strength design and the working efficiency of the present invention, the crushing There are more than one head 7, and each crushing head 7 is connected to the pin seat 3 by a pin 8.

Embodiment 3

[0030] This embodiment is further improved on the basis of embodiment 2, as figure 1 and figure 2 As shown, in order to evenly bear the force on each crushing head 7 and reduce the failure rate of the present invention, the crushing heads 7 are evenly distributed in a ring shape relative to the axis of the rotating shaft 9 .

[0031] Described pin seat 3 is made up of upper base plate and lower base plate parallel to each other, two ends are fixedly connected with upper base plate and lower base plate respectively, the upper base plate and lower base plate are all provided with pin holes, and upper base plate and lower base plate The pin holes are arranged in pairs, and the hollow area of the sleeve is connected with the two end faces of the pin seat 3 .

[0032] The pin seat 3 of the above structural form is simple in structure, is convenient to obtain the pin seat 3 of less weight, is conducive to the starting of drive motor like this, and the sleeve that is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com