Comprehensive optimized smoke discharge waste heat deep recycle system of smoke in thermal power plant

A technology for recovery systems and thermal power plants, applied in preheating, liquid degassing, feed water heaters, etc., can solve problems such as energy loss, exhaust gas temperature reduction, and limited range of exhaust gas temperature, so as to improve unit efficiency and reduce Effect of cooling water consumption and reducing steam extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

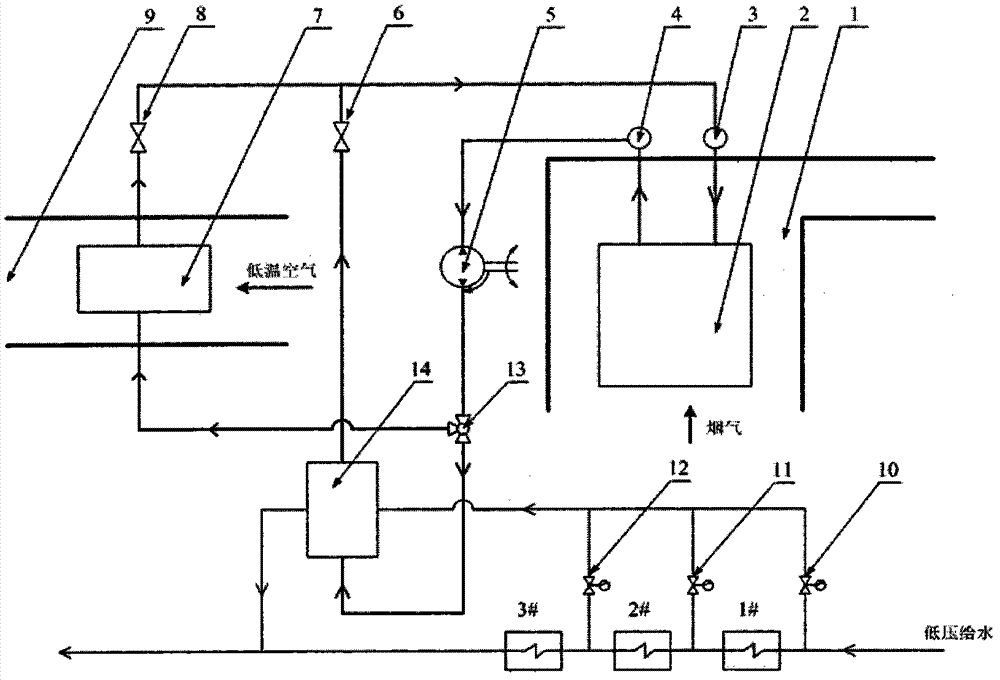

[0018] Comprehensive optimization of flue gas in thermal power plants Exhaust waste heat deep recovery system adds a flue gas cooler 2 to the flue after the booster fan and before the desulfurization tower, and introduces the feed water from the front of the first-stage low-pressure heater to the flue gas cooler 2 through the pipeline. After heating, return to the second-stage low-pressure heater to reduce the exhaust gas temperature from 152°C to 108°C, and heat the low-pressure feed water from 83.8°C to 103.7°C.

[0019] In this embodiment, the exhaust waste heat deep recovery system for comprehensive optimization of flue gas in a thermal power plant further includes a smoke exhaust heat utilization device. The smoke exhaust waste heat utilization device includes a feed water heater. When the ambient temperature is high, the high temperature circulating water coming out of the flue gas cooler passes through the feed water heater to heat the condensed water.

[0020] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com