Device and method for treating VOCs

A gas and catalytic cracking technology, applied in the field of VOCs treatment, can solve the problems of human health damage, stimulation, toxicity, etc., achieve the effects of reducing energy consumption and operating costs of the device, simple and efficient recovery and utilization, and reducing the amount of cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

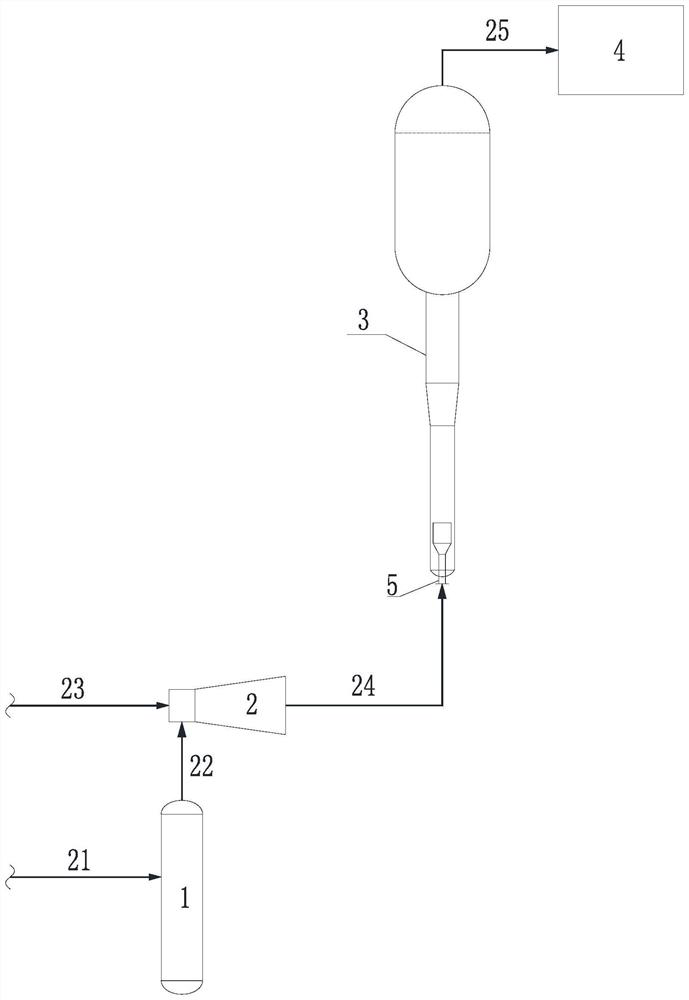

[0045] Such as figure 1 As shown, the device for treating VOCs in this embodiment includes a buffer tank 1, a pressurized injector 2, a catalytic cracking riser reactor 3 and a separation and purification system 4 of a catalytic cracking device connected in sequence. The VOCs raw material gas enters the buffer tank 1 through the upstream pipeline 21 for buffering and then enters the booster injector 2. After being pressurized by the existing water vapor in the refinery, it enters the pre-lift nozzle 5 through the outlet pipeline of the booster injector 2 to increase the After the compressed VOCs gas is reacted in the catalytic cracking riser reactor 3, the reaction gas enters the separation and purification system 4 of the catalytic cracking unit along with the catalytic cracking reaction oil gas.

[0046] The upstream VOCs raw material gas comes from the tail gas of the desulfurization unit, the tail gas of the alkali slag tank, the LPG sweetening tail gas of the coking unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com