Buoy release and recovery system based on separable inner turret mooring system

A mooring system and recovery system technology, applied in the field of buoy release and recovery systems, can solve the problems of inability to seal the liquid transmission piping system in time, difficulties in the cable traction and recovery process, and liquid leakage, etc., and achieve efficient and simple release and recovery processes. Save manpower and material resources and maintain a balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

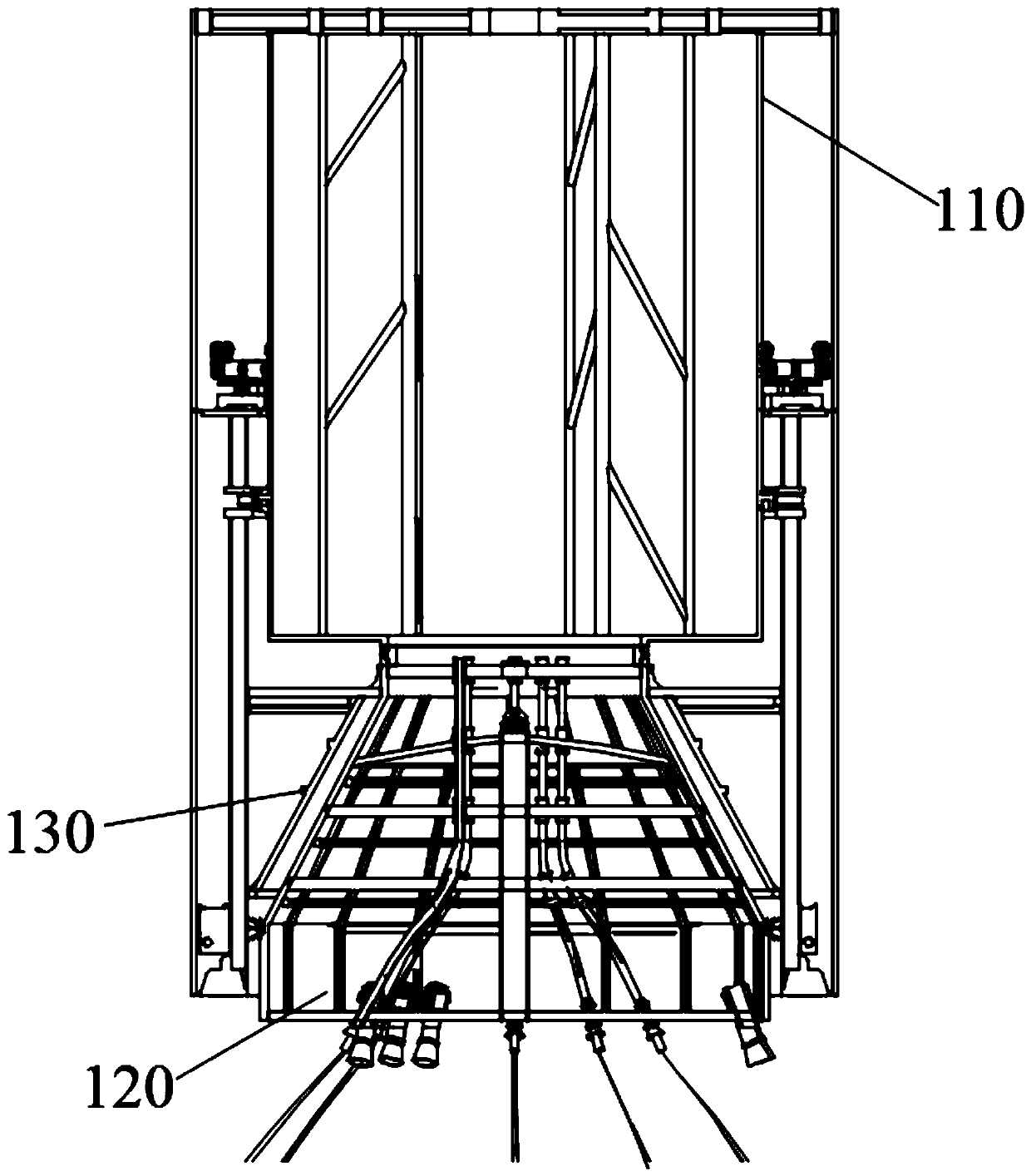

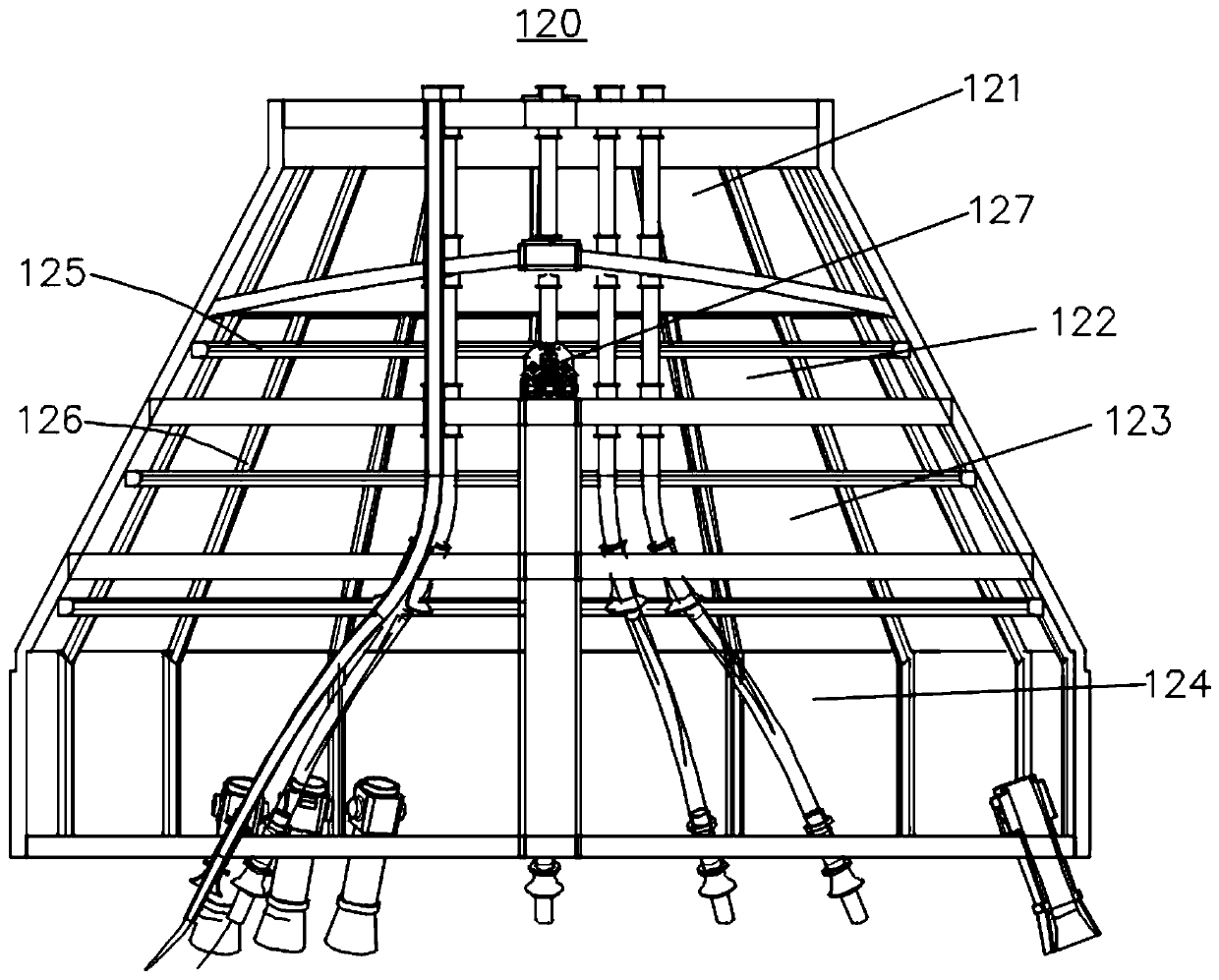

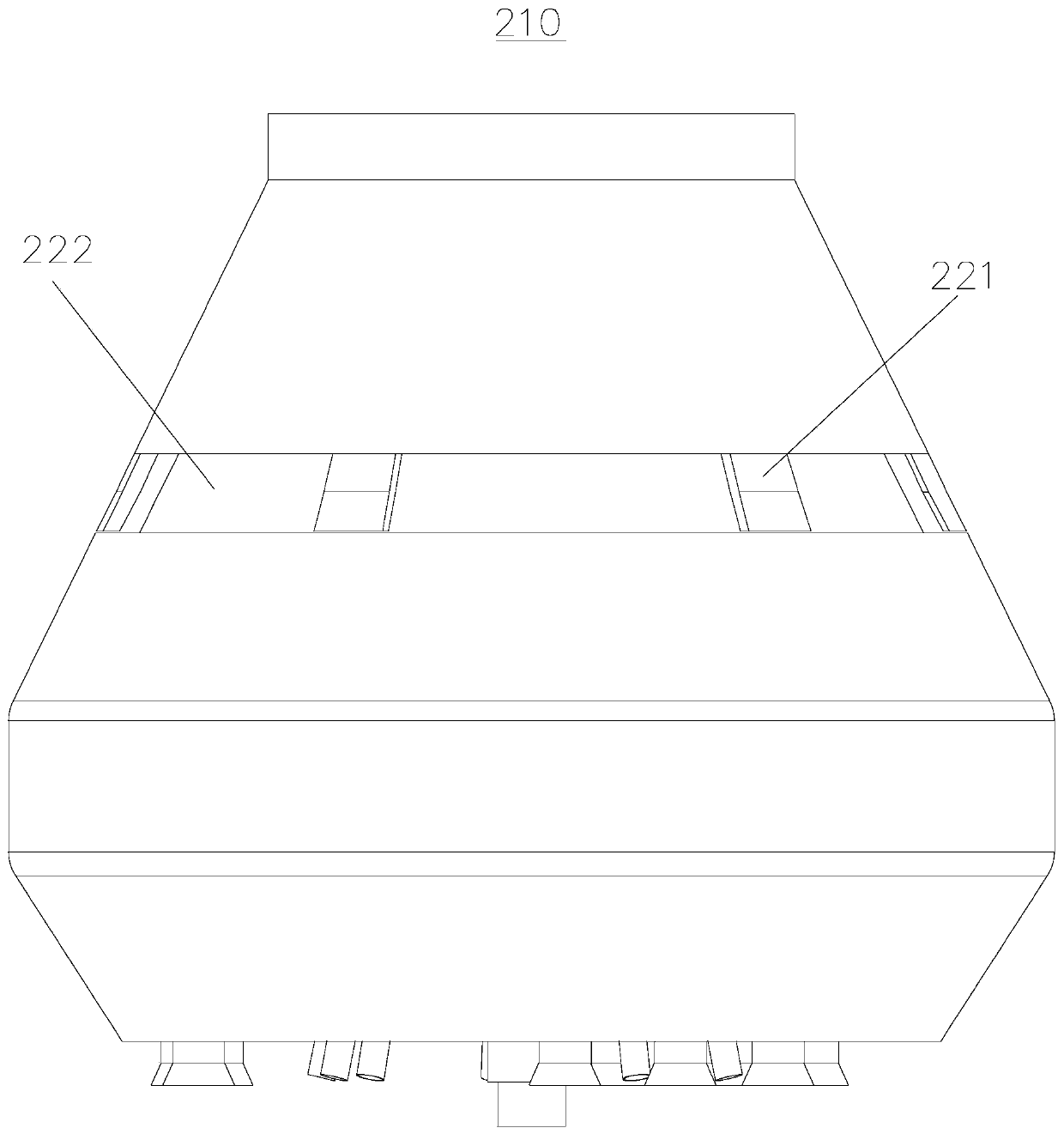

[0031] Such as Figure 3-8 Shown is the buoy release and recovery system based on the detachable internal turret mooring system of the present invention, the system includes a buoy 210, a barrier device 220, a liquid transmission piping system 230, an anchor chain connection device 240 and a clamping device 250 .

[0032] The buoy 210 includes an outermost anti-rolling water tank 213 , a ballast water tank 212 inside the anti-rolling water tank 213 and a sealed cabin 211 inside the ballast water tank 212 , and the cabins are mutually sealed. The anti-rolling water tank 213 provides a larger restoring moment when the buoy 210 tilts by injecting a certain amount of water, and can reduce the sway of the buoy 210 in the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com