Method for producing hydroxy alkanoic acid polymer

A technology of hydroxyalkanoic acid and production method, applied in biochemical equipment and methods, microorganisms, fermentation and other directions, can solve the problems of increasing production cost, affecting the scope of application, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

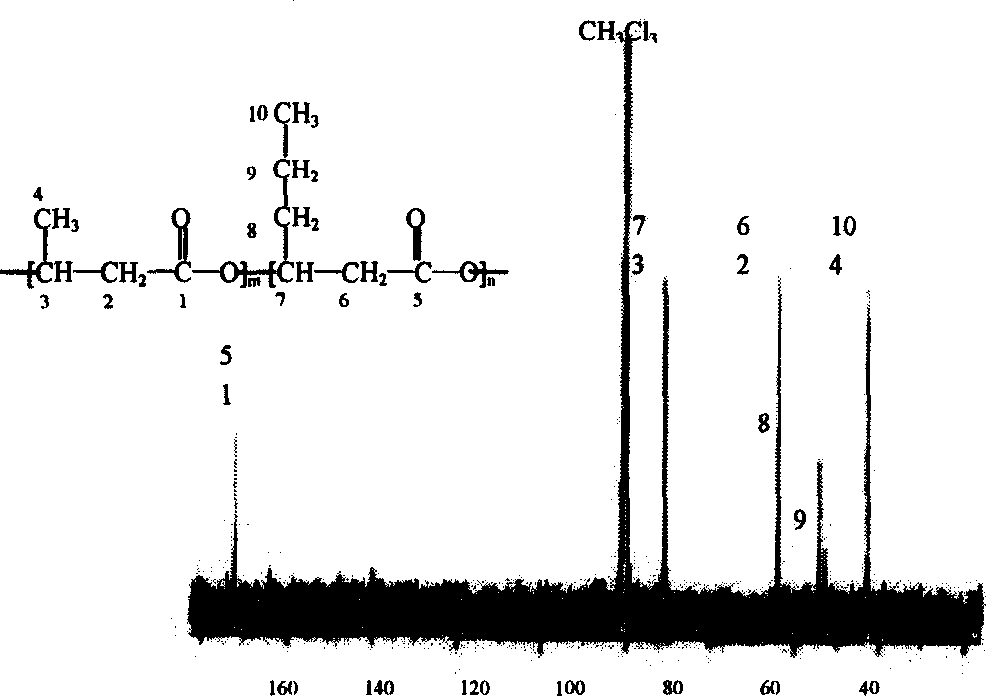

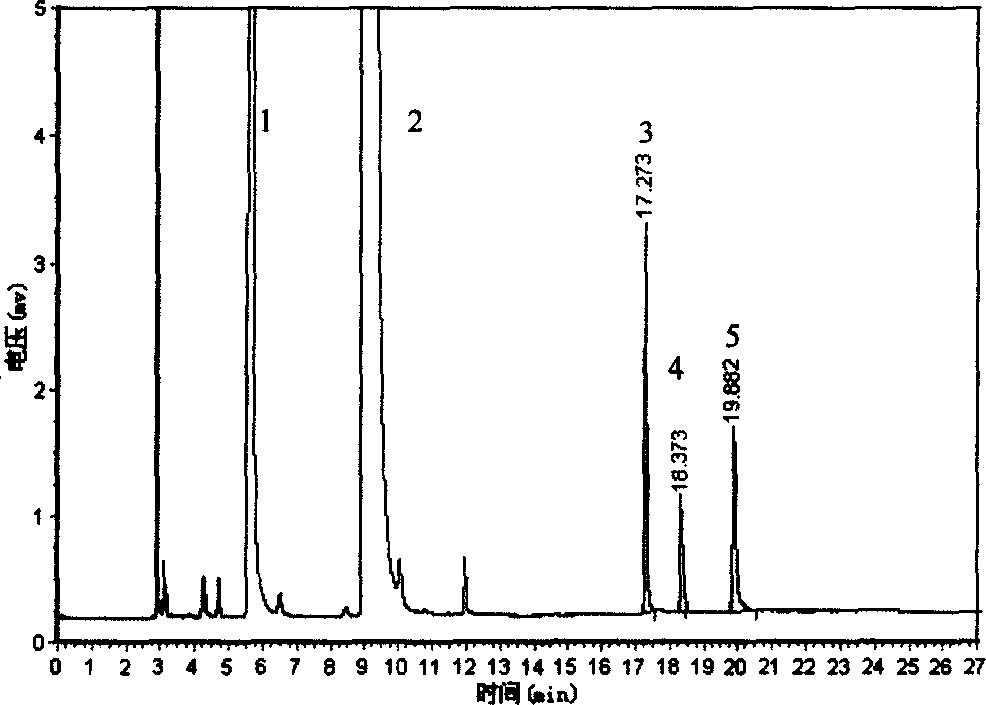

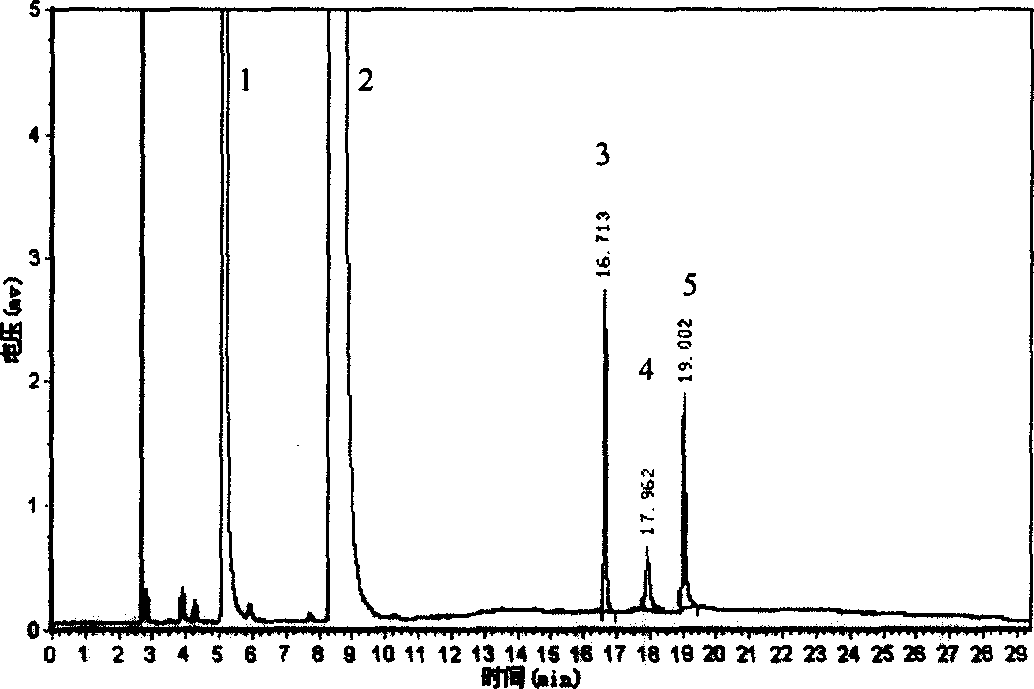

Image

Examples

Embodiment 1

[0070] Embodiment 1, use glucose as the fermentative production of carbon source synthetic P (HBHH)

[0071] (1) Inclined plane and shake flask seed culture

[0072] Inoculate the preserved S. fredii strain on the slant medium, activate it twice in an incubator at 30°C, transfer it to a shake flask containing a shake flask seed medium, and activate it twice again, and wait for the next stage of shaking Flask cultured for 16 hours, when the bacterial cell concentration reached 1.79g stem cells / L (OD 600 When the value is 3.5), the cell growth is still in the logarithmic growth phase, which is used as the seed liquid of the seed tank for subsequent use.

[0073] (2) Seed tank seed culture

[0074] Use a 10L self-control tank as the seed tank, use fermented seed medium, the filling coefficient is 0.7, insert the seed solution, the inoculation amount is 8%, cultivate at 30°C, adjust and control the pH to 7.0-7.2 through 6mol NaOH solution, and maintain dissolved oxygen Over 20%...

example 2

[0082] Example 2, using starch hydrolyzate as the fermentative production of carbon source synthesis P (HBHH)

[0083] (1) Inclined plane and shake flask seed culture

[0084] Inoculate the preserved S. fredii strain on the slant medium, activate it twice in an incubator at 28°C, transfer it to a shake flask containing a shake flask seed medium, and activate it twice again, and wait for the next stage of shaking Flask cultured for 18h, when the bacterial cell concentration reached 2.81g stem cells / L (OD 600 When the value is 5.5), the cell growth is still in the logarithmic growth phase, and it is used as the seed liquid of the seed tank for subsequent use.

[0085] (2) Seed tank seed culture

[0086] Use a 10L self-control tank as the seed tank, use fermented seed medium, the filling coefficient is 0.7, insert the seed liquid, the inoculation amount is 9%, cultivate at 30°C, adjust and control the pH to 7.0-7.2 with 6mol NaOH solution, and maintain dissolved oxygen Over 20% ...

Embodiment 3

[0093] Embodiment 3, use waste molasses as the fermentative production of carbon source synthesis P (HBHH)

[0094] (1) Incline and shake flask culture

[0095] Inoculate the preserved S. fredii strain on the slant medium, activate it twice in an incubator at 32°C, transfer it to a shake flask containing a shake flask seed medium, and activate it twice again, and wait for the next stage of shaking Flask cultured for 18 hours, when the bacterial cell concentration reached 2.6g stem cells / L (OD 600 When the value is 5.2), the cell growth is still in the logarithmic growth phase, which is used as the seed liquid of the seed tank for subsequent use.

[0096] (2) Seed tank seed culture

[0097] Use a 10L self-control tank as the seed tank, use fermented seed medium, the filling coefficient is 0.7, insert the seed liquid, the inoculum amount is 10%, cultivate at 30°C, adjust and control the pH to 7.0-7.2 through 6mol NaOH solution, and maintain dissolved oxygen Over 20% saturatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com