Inferior raw oil lightening treatment process and system

A technology of inferior raw material oil and treatment process, which is applied in the direction of hydrotreating process, hydrocarbon oil treatment products, petroleum industry, etc., to achieve long-term stable operation and reduce the effect of coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

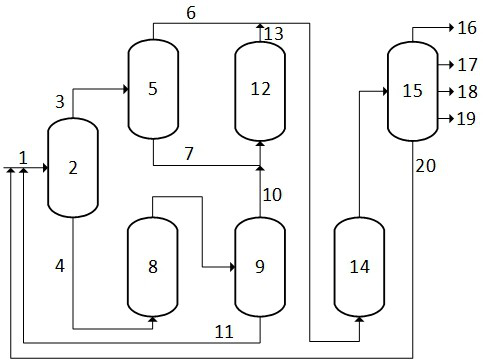

[0050] Embodiment 1 adopts the present invention figure 1 As shown in the process flow, the solvent A used in the solvent deasphalting unit is a mixed solvent of n-butane and n-pentane, wherein the weight fraction of n-pentane is 50%, the extraction temperature is 135°C, the pressure is 4.0Mpa, and the volume ratio of solvent to oil is 5.0; The solvent B used in the gum unit is a compound solvent of propane and dioctadecyl maleate, the content of propane is 95wt%, the extraction temperature is 115°C, the pressure is 10Mpa, and the volume ratio of solvent to oil is 6.0. Two ebullating bed hydrogenation reactors are installed in the ebullating bed hydrogenation reaction zone, connected in series, the reaction pressure is 16MPa, the hydrogen to oil volume ratio is 800, the reaction temperature of the first reactor is 410°C, and the liquid hourly volume space velocity is 0.35h -1 , the reaction temperature of the second reactor is 420°C, and the liquid hourly volume space velocity...

Embodiment 2

[0052] Embodiment 2 adopts the present invention figure 1 As shown in the process flow, the solvent A used in the solvent deasphalting unit is n-butane solvent, the extraction temperature is 125°C, the pressure is 4.0Mpa, and the volume ratio of solvent to oil is 5.0; the solvent B used in the degumming unit is propane and maleic acid Dioctadecyl ester compound solvent, propane content is 99wt%; extraction temperature is 110°C, pressure is 7Mpa, volume ratio of agent to oil is 10.0. Two ebullating bed hydrogenation reactors are set up in the ebullating bed hydrogenation reaction area, connected in series, the reaction pressure is 16MPa, the hydrogen oil volume ratio is 800, the reaction temperature of the first reactor is 405°C, and the liquid hourly volume space velocity is 0.35h -1 , the reaction temperature of the second reactor is 420°C, and the liquid hourly volume space velocity is 0.4h -1 . The hydroprocessing reaction zone adopts a fixed-bed reactor with an average b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com