Patents

Literature

97results about How to "Reduce gum content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

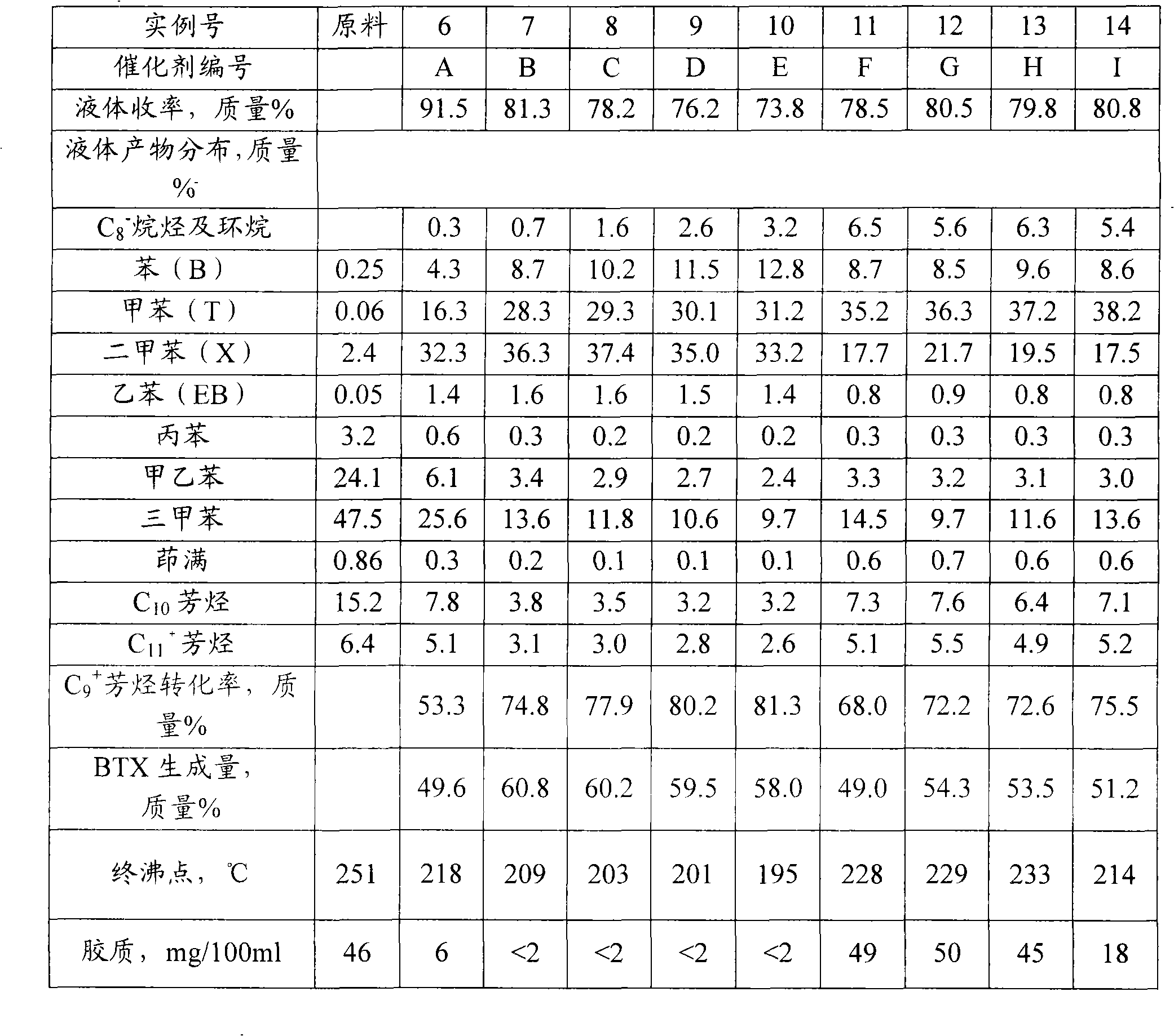

Hydrocarbons process liquid production upgrading catalyzer and upgrading method thereof

ActiveCN101134167AIncreased light aromatics contentReduce carbon deposition ratePhysical/chemical process catalystsNaphtha reformingIridiumNaphtha

The liquid hydrocarbon modifying catalyst consists of heat resisting inorganic oxide, Ir in 0.1-5.0 wt% of the inorganic oxide, and halogen in 0.01-3.0 wt% of the inorganic oxide. The catalyst is used in modifying naphtha product, and can raise benzene, toluene and xylene contents in the modified product, raise ethyl benzene converting rate, and lower the carbon deposit during the reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pretreating method for diesel-fuel of poor quality

InactiveCN1670129ALower the initial reaction temperatureExtended operating cycleHydrocarbon oils refiningSorbentFiltration

The invention discloses a pretreating method for diesel-fuel of poor quality which comprises contact low grade diesel raw material with adsorbent for adsorption filtration under the condition of adsorption temperature 50-150 deg. C, adsorption volume air rapid 1.0-5.0h-1, contacting desorption agent after adsorbent saturation for desorption, then carrying out coke burning reproduction after multitime of adsorption-desorption of the adsorbent. The adsorbent with polar reclamation can be used repeatedly.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

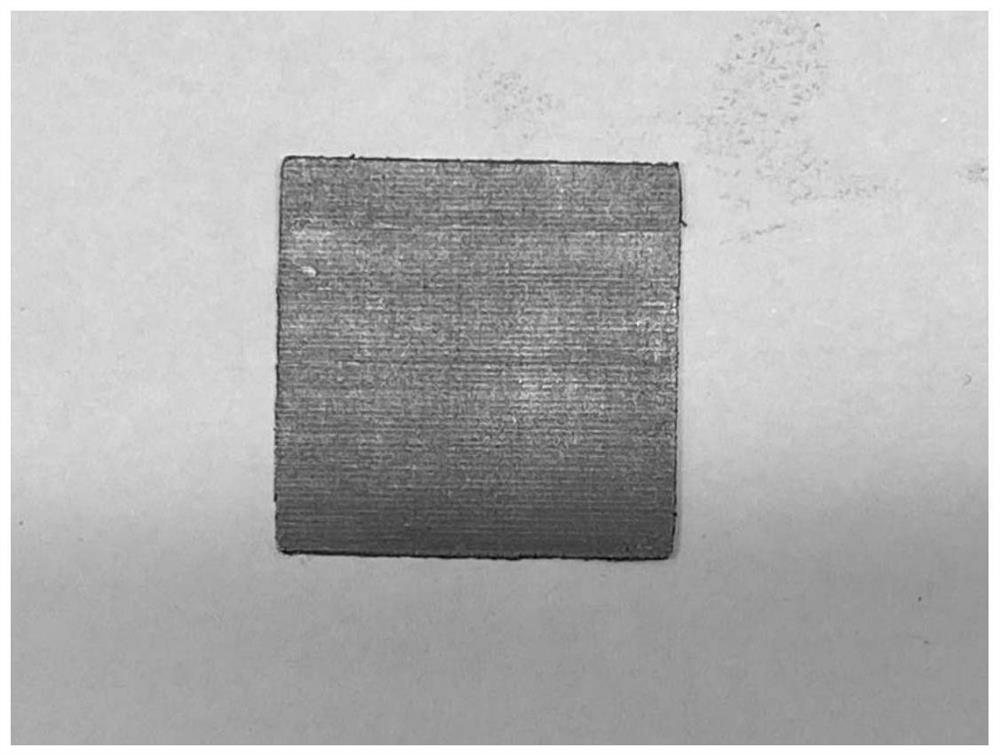

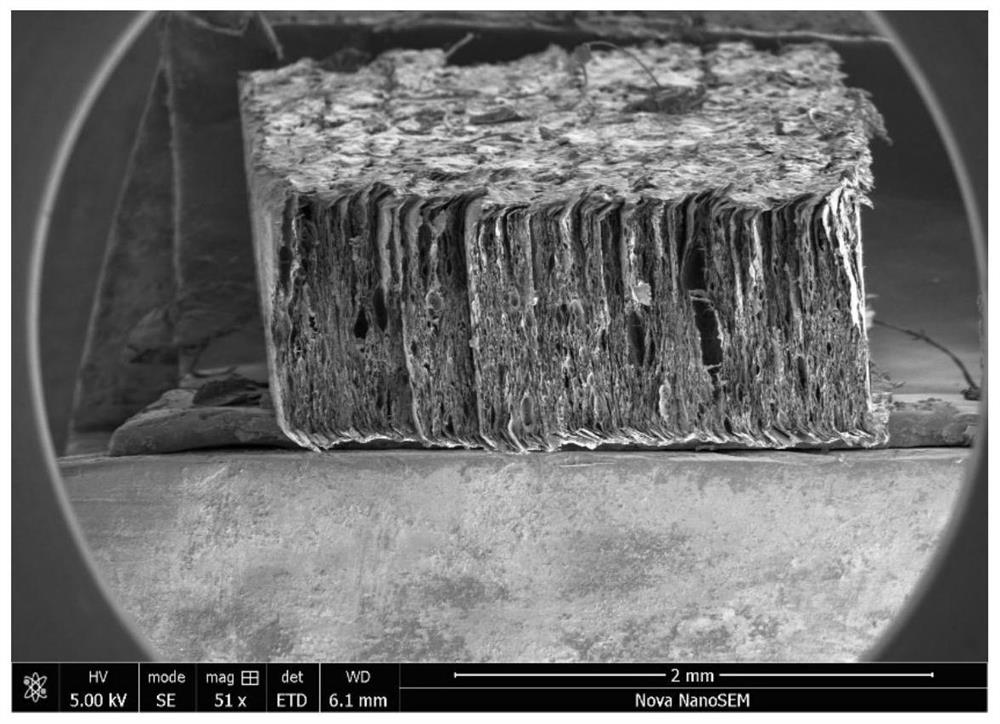

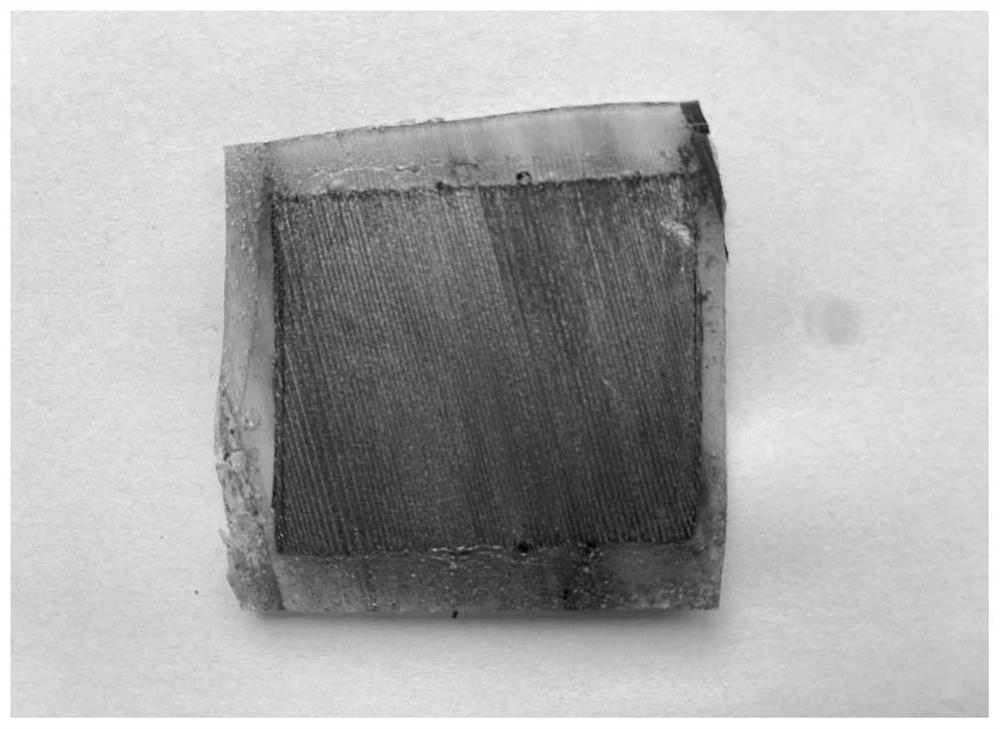

Graphene composite heat-conducting gasket and preparation method thereof

ActiveCN113510979AReduce gum contentImprove reliabilityLamination ancillary operationsLaminationPolymer scienceGraphite

The invention provides a graphene composite heat-conducting gasket which comprises a plurality of layers of graphene foam films arranged in the thickness direction and an adhesive, and the graphene foam films account for 50 wt.%-95 wt.%. The invention also provides a preparation method of the graphene composite heat-conducting gasket, wherein the preparation method comprises the steps: stacking the graphene foam films layer by layer and putting the graphene foam films into a mold, and applying pressure to tightly fit the films; uniformly coating the periphery of the graphene heat-conducting foam films subjected to pressure application with the adhesive, so as to completely coating a plurality of layers of graphene heat-conducting foam films into a block body; after the block body is cured and formed, cutting the block body into sheets along the stacking direction; dipping the cut sheets in dipping glue, taking out the sheets, and carrying out hot press molding on the taken-out sheets; and trimming the edge of the formed sheets, and removing an adhesive bonding area on the edge to obtain the graphene composite heat-conducting gasket. The heat-conducting gasket is low in density, high in heat conductivity in the thickness direction and low in heat resistance.

Owner:CHANGZHOU FUXI TECH CO LTD

Vacuum rush gum forming method of fiber-reinforced resin matrix compound material

The invention relates to a resin flowing compound material forming method which is aided by vacuum. A fiber-reinforced material is tailored and then paved in a mould cavity according to the design of layer quantity and structure of a product. Resin and firming agent are prepared into dipping glue solution which is evenly coated in the mould cavity and ensured to permeate the fiber-reinforced material. A mould is sent into a vacuum bag which is sealed and then vacuumized till a vacuum bag film closely clings to the surface of the reinforced material supported by the mould. A panel with elastic planes is used for expel foams and surplus glue solution in the vacuum bag to the edges outside the mould cavity. Then, in the conditions of normal temperature or heating and vacuum, the product gradually undergoes solidification and demoulding. The method can improve the mechanical properties and the surface quality of the compound material product, reduce the cost on production apparatuses and auxiliary materials and simplify the method operation.

Owner:SHENZHEN OYA CARBON TECH +1

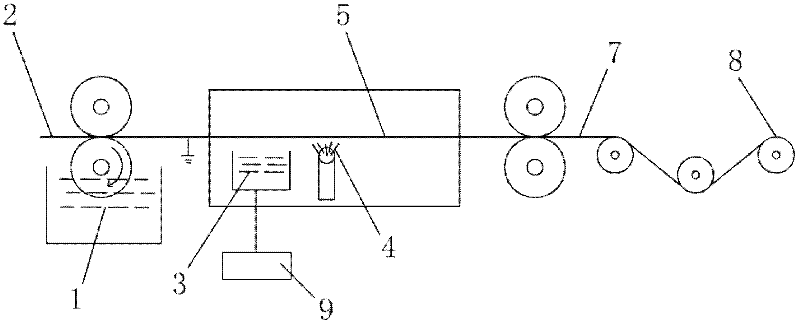

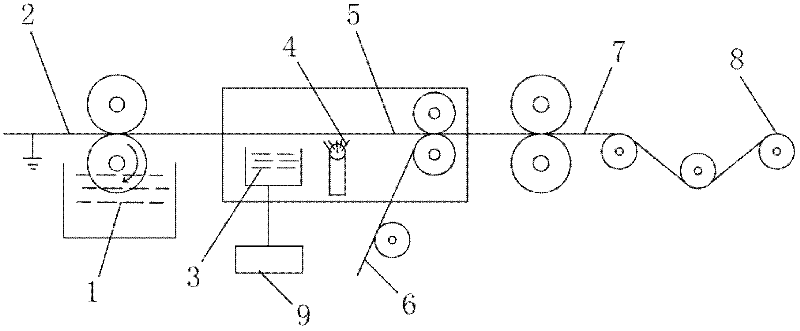

Fiber bundle dividing and washing method and device

ActiveCN101851789AGuaranteed cleanlinessHit evenlyMechanical treatmentFibre treatment to obtain bast fibreCardingFiber bundle

The invention relates to a fiber bundle dividing and washing method and a fiber bundle dividing and washing device. The method comprises the following steps of: 1) arranging a plurality of groups of fiber dividing and washing units and a fiber output unit on a frame, wherein each unit is provided with a running rotating crawler; 2) passing a feeding roller through a crawler input end of each fiber dividing and washing unit so as to convey the fiber bundle forward, making the fiber bundle enter a fiber dividing and washing area which is provided with a beater and a fiber dividing roller at intervals, simultaneously opening a high pressure water pipe which is arranged above the beater and the fiber dividing roller, and performing washing soaking, beating, carding and fiber dividing on the fiber bundle edges; 3) feeding the fiber treated by the previous fiber dividing and washing unit to the next fiber dividing and washing unit for continuous fiber dividing and washing; and 4) feeding the fiber treated by the last fiber dividing and washing unit into a fiber dividing input area, performing water squeezing operation through a squeezing roll, feeding the fiber into a cloth arrangement mechanism, arranging and folding the strip-shaped fiber through the cloth arrangement mechanism, and feeding the fiber into a fiber storage box. The fiber bundle dividing and washing method and the fiber bundle dividing and washing device can be widely applied to fiber dividing and washing treatment for various bast fibers, leaf fibers, and grass family fibers.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +3

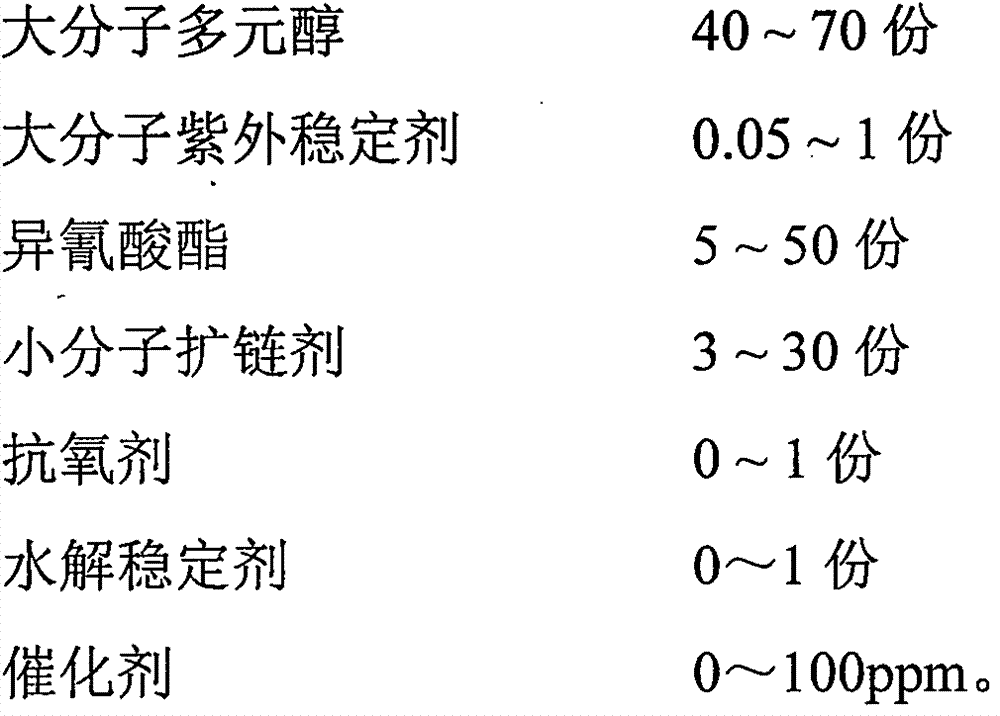

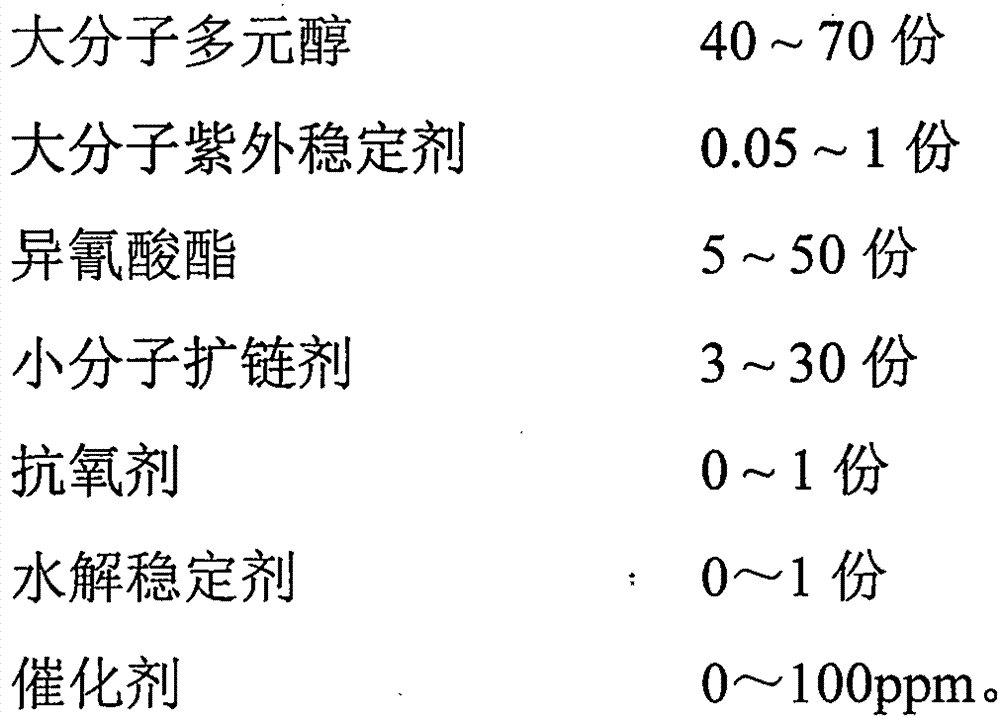

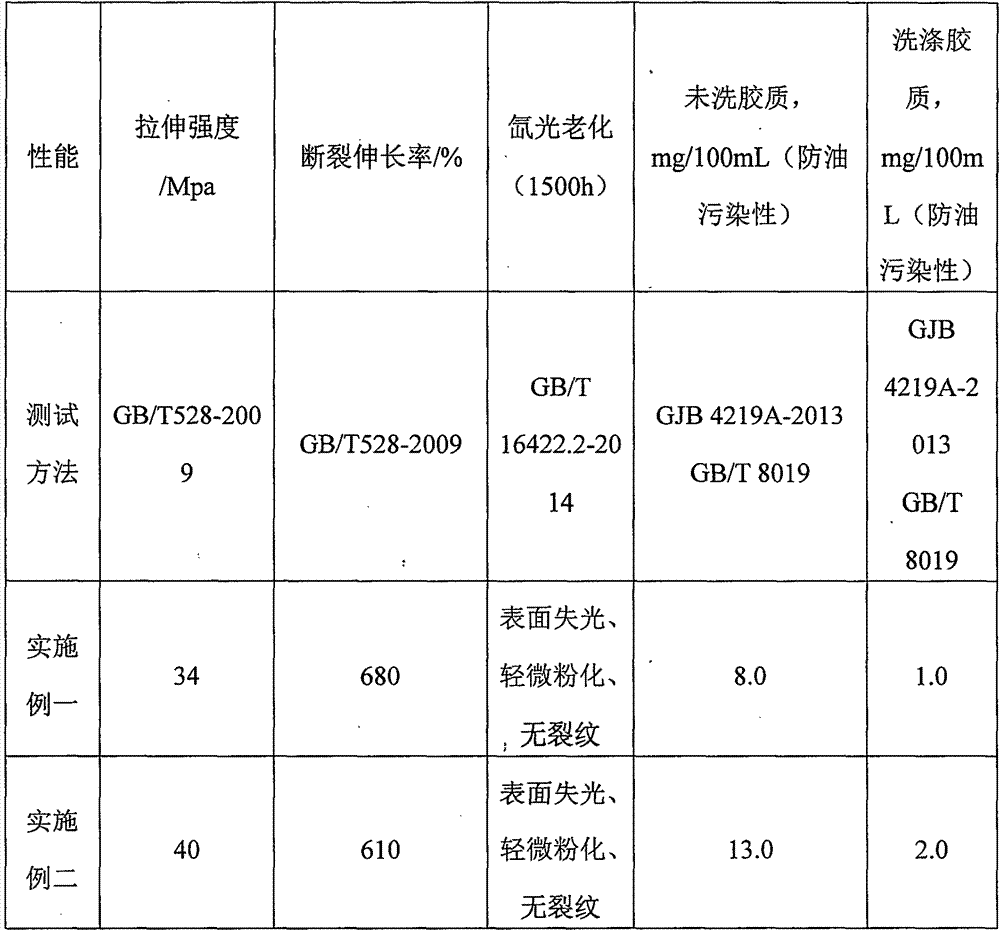

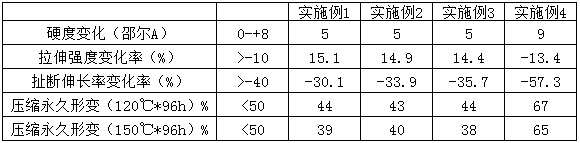

Oil-resistant weather-resistant thermoplastic polyurethane elastomer and preparation method thereof

The invention discloses an oil-resistant weather-resistant thermoplastic polyurethane elastomer and a preparation method thereof. An oil-resistant weather-resistant thermoplastic polyurethane composite material comprises the following raw material components in parts by weight: 40 to 70 parts of macromolecular polyhydric alcohols, 0.05 to 1 part of a macromolecular ultraviolet stabilizing agent, 5 to 50 parts of isocyanate, 3 to 30 parts of a micromolecular chain extending agent, 0 to 1 part of an antioxidant, 0 to 1 part of a hydrolytic stabilizing agent, and 0 to 100 ppm of a catalyst. The oil-resistant weather-resistant thermoplastic polyurethane elastomer can keep good mechanical properties of the oil-resistant weather-resistant thermoplastic polyurethane elastomer for a long time after being in contact with gasoline, diesel and aviation kerosene, and does not cause pollution to oil products; the colloid content of the oil products is low; through long-term oil product soaking, the prepared oil-resistant weather-resistant thermoplastic polyurethane elastomer still has high weather resistance; the ultraviolet radiation resistance is not influenced; the failure of stabilizing performance caused by a large amount of extraction loss of various types of stabilizing agents because of the oil products is avoided; the oil-resistant weather-resistant thermoplastic polyurethane elastomer has the characteristics of oil resistance and weather resistance.

Owner:SHANGHAI HENGAN POLYURETHANE CO LTD

Rubber composition with low breathability

The invention relates to a rubber composition with a low breathability. The rubber composition is prepared by using 50-100 parts of halogenated butyl rubber as a main raw material, using 10-60 parts of coal-based composite material and 10-70 parts of carbon black as a filling-reinforcing agent, matching with a vulcanizing agent, an accelerant, an activating agent, a softening agent and other processing accessory ingredients. The rubber composition is filled by the coal-based composite material and the carbon black commonly; compared with the normal rubber composition only filled with the carbon black, the rubber composition of the invention has low breathability, good flexing resistance property and strength property which can satisfy the using requirement; and the rubber composition is suitable for the inner liner of the tyre.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Method for preparing phenol compound and clean fuel oil from coal tar

InactiveCN103205275AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationResource utilizationDecomposition

The invention relates to a method for preparing a phenol compound and a clean fuel oil from coal tar, and belongs to the fields of coal chemical industry and energy technology. The method is characterized by comprising the following steps of: separating the coal tar into a light oil and a tower-bottom heavy oil in the manner of catalyst distillation; performing delay coking on the tower-bottom heavy oil; mixing the tower-bottom heavy oil with the coal tar and distilling again; performing alkaline cleaning on the light oil and filtering, thereby obtaining an alkaline phenol salt and the phenol-removed light oil; steaming and blowing the neutral phenol salt in a steaming and blowing kettle, thereby obtaining the clean phenol salt; decomposing the clean phenol salt by using a dilute sulphuric acid, thereby obtaining crude phenol; or respectively treating the crude phenol and sodium carbonate in a decomposition tower by adopting the continuous CO2 decomposition process; injecting the phenol-removed light oil into a reactive distillation tower filled with a molecular sieve / alumina catalyst and performing reactive distillation; directly leading the distillate oil after the reactive distillation into a hydrogenation refining tower of a hydrogenation reactor; and performing the hydrogenation refining, thereby obtaining the clean fuel oil. The phenol compound and the clean fuel oil with high additional values are produced by utilizing the coal tar, thereby providing a new way for the resource utilization of the coal tar. In addition, the method provided by the invention is good in economic benefits and industrial application prospects.

Owner:DALIAN UNIV OF TECH

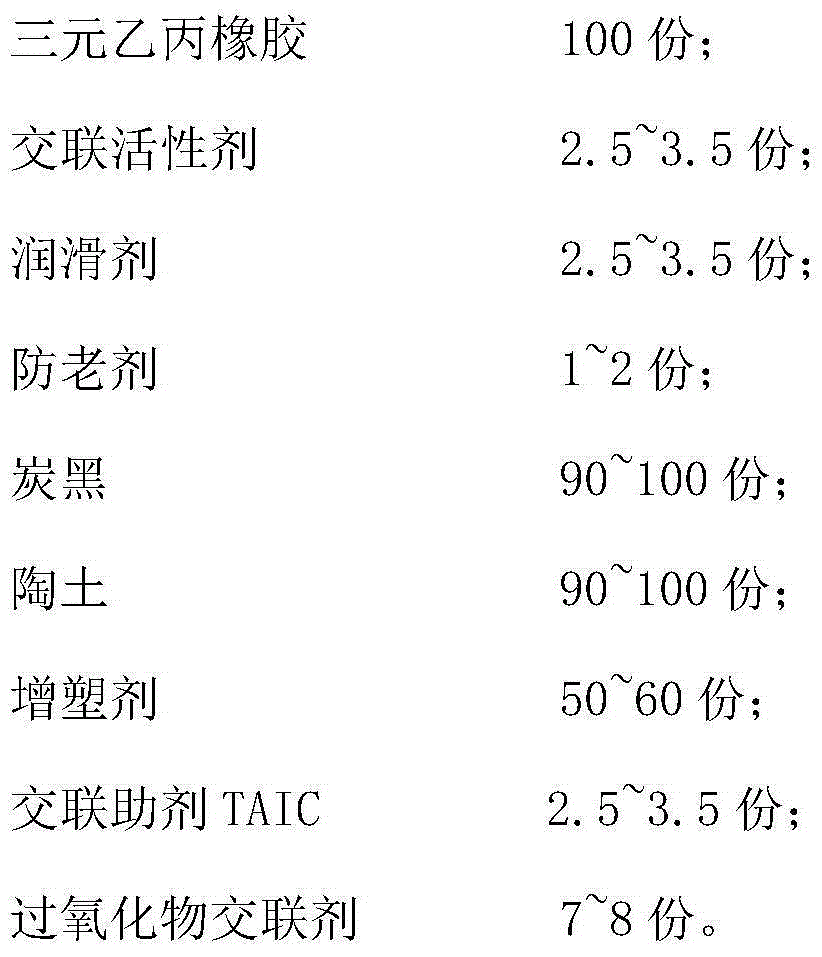

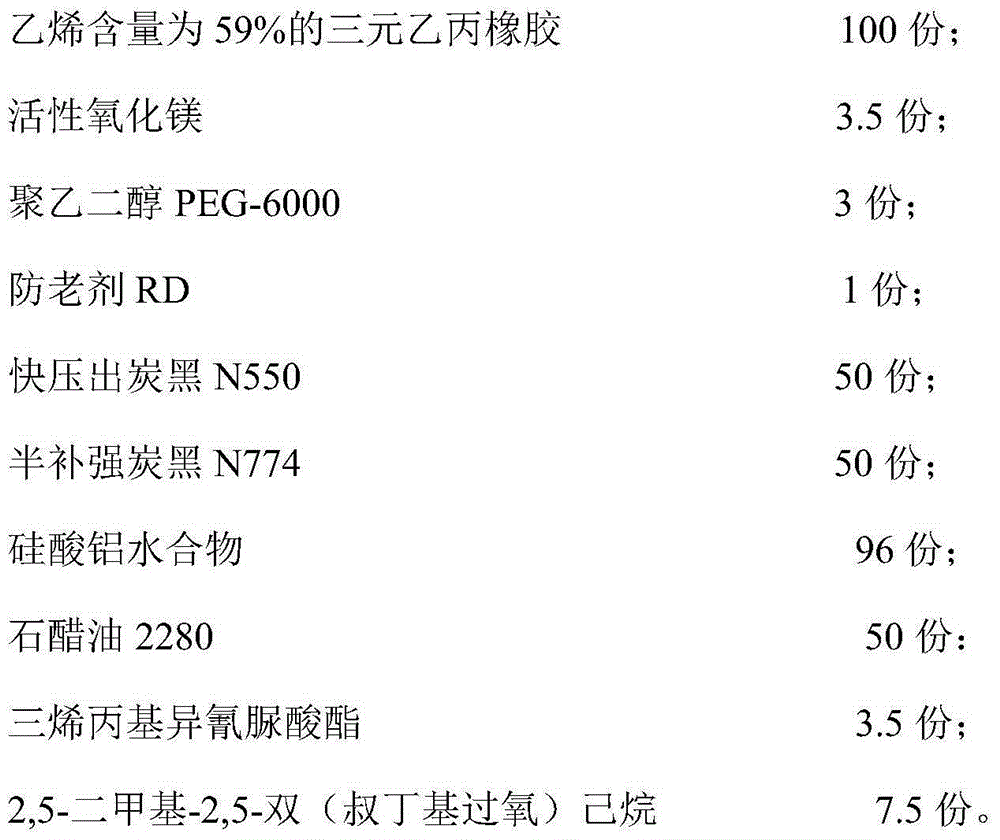

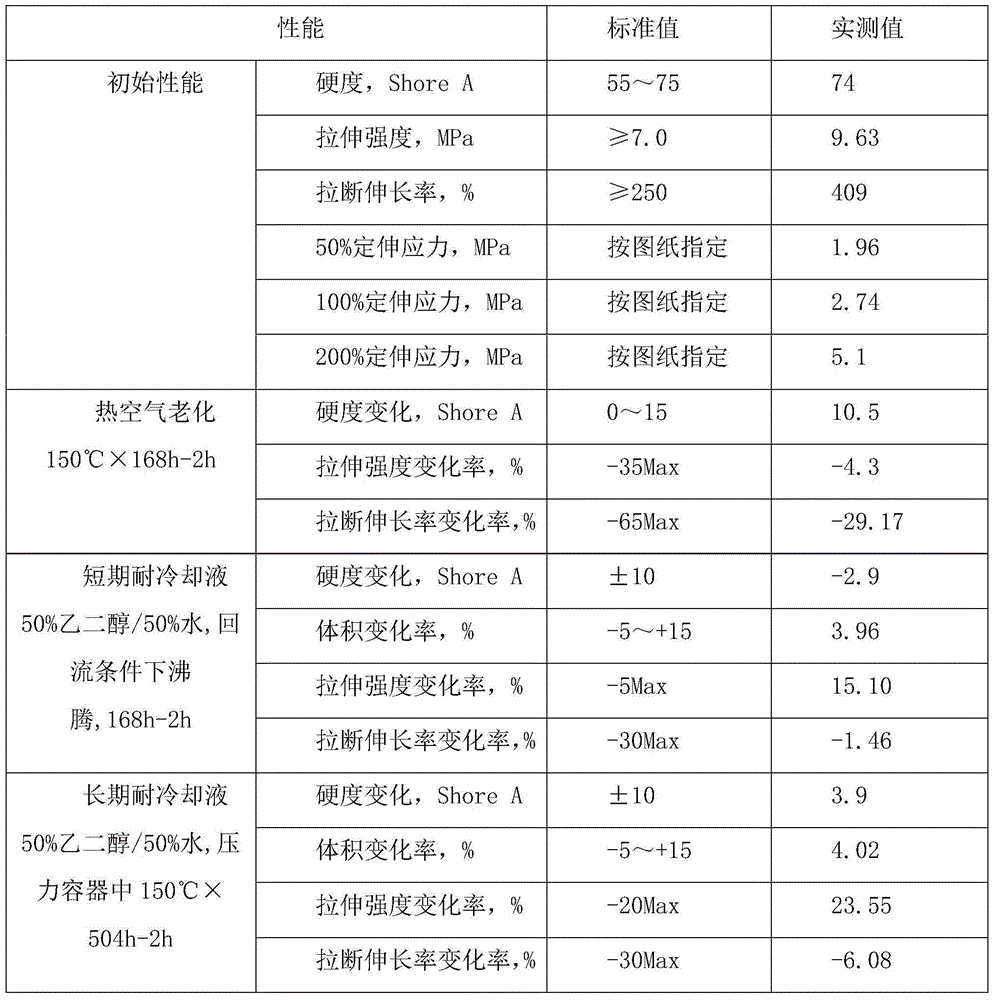

Rubber composition used for production of automobile engine coolant hose inner and outer rubber layers and production method thereof

InactiveCN105017658AImprove resistance to oxidative degradationAvoid effectivenessCross-linkActive agent

A rubber composition used for production of automobile engine coolant hose inner and outer rubber layers comprises the following feedstock components: EPDM rubber, a cross-linking active agent, a lubricant, an antioxidant, carbon black, clay, a plasticizer, crosslinking aid TAIC, and a peroxide crosslinking agent. The rubber composition used for production of the automobile engine coolant hose inner and outer rubber layers uses the EPDM rubber, the crosslinking aid TAIC and the peroxide crosslinking agent TAIC 101-50D-PD (namely, 2,5 dimethyl-2,5-bis (t-butylperoxy) hexane) for combination to improve optimal thermal and chemical stability, meanwhile by adding of the cross-linking active agent magnesium oxide as an acid-acceptor, the peroxide invalidation can be prevented, and rubber products are given better 150 DEG C high temperature resistance and long-term coolant resistance by the peroxide vulcanizing way.

Owner:QINGDAO SUNSONG CO LTD

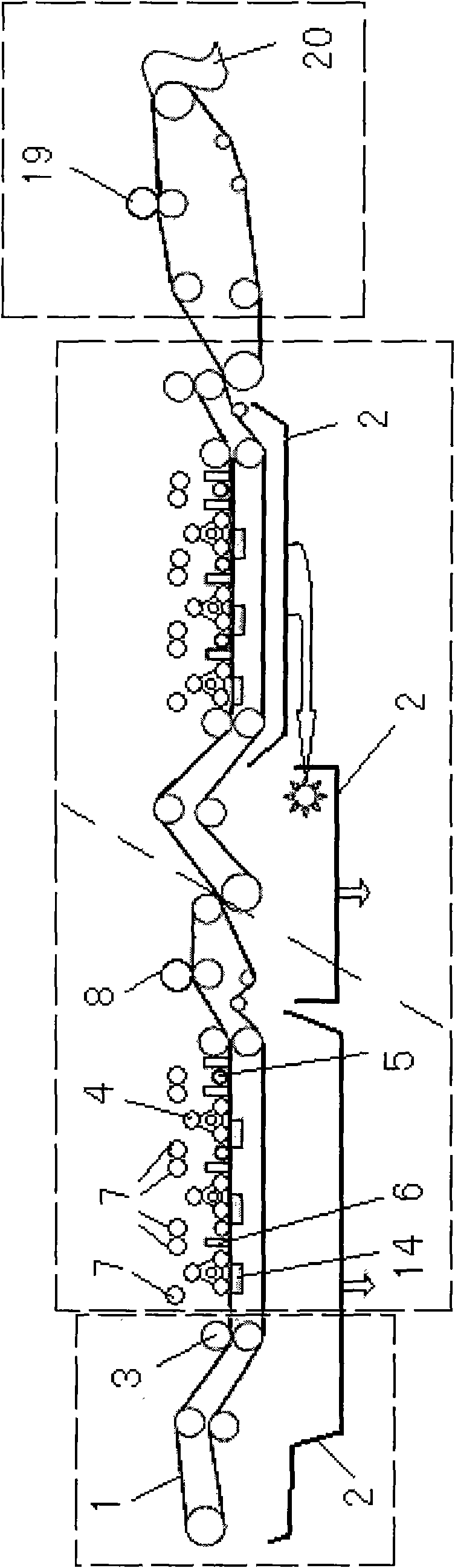

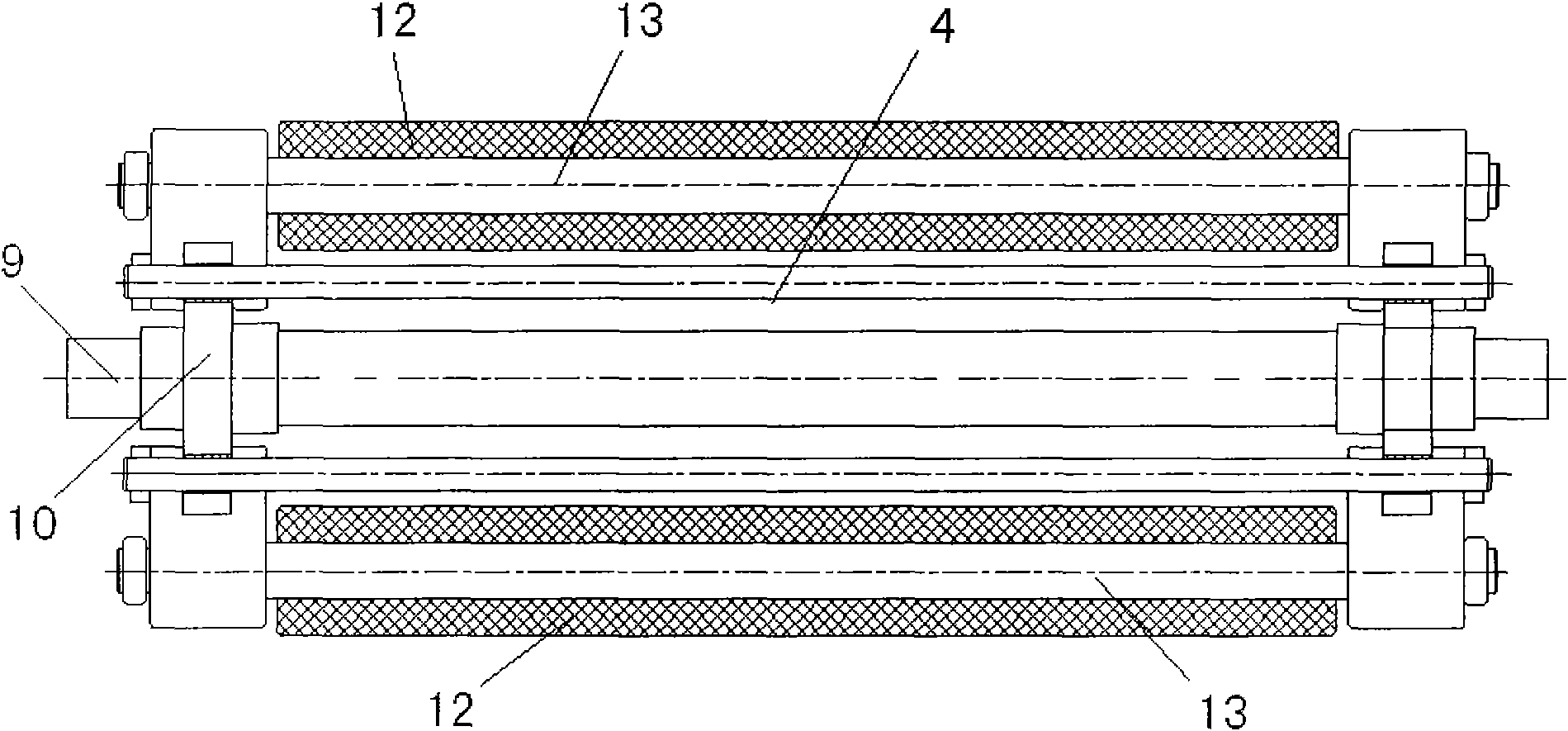

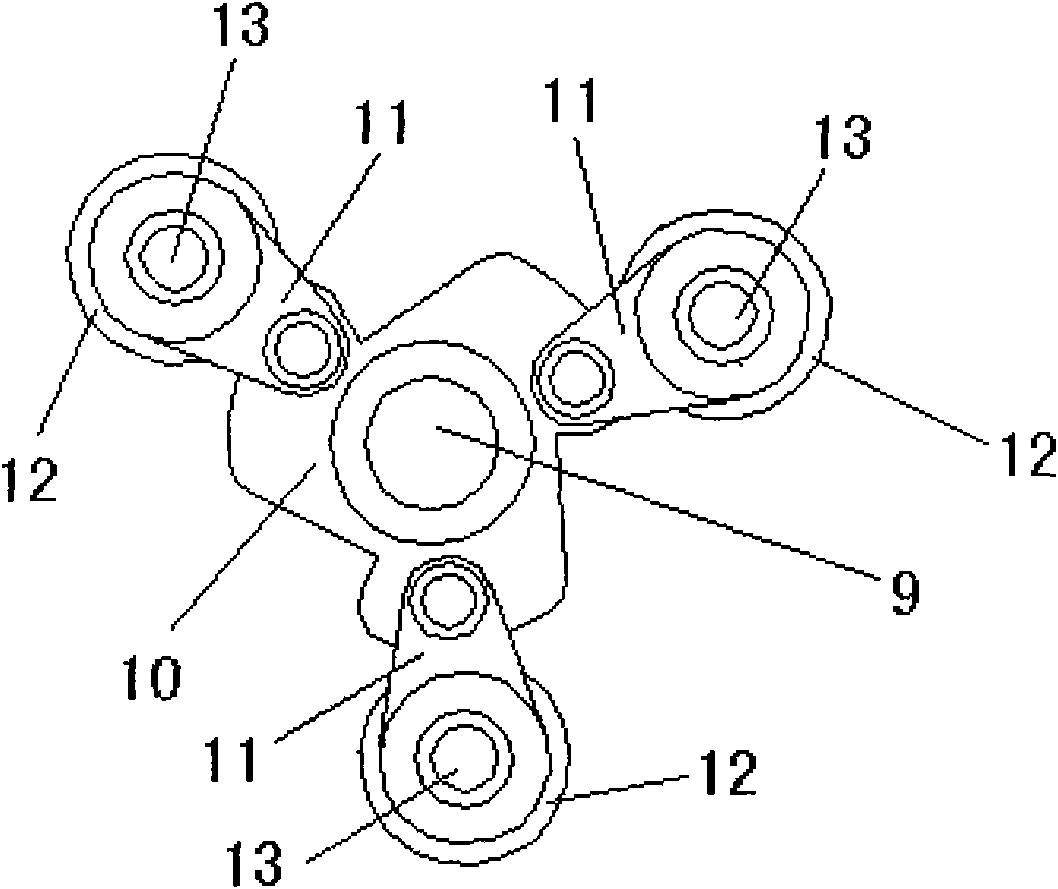

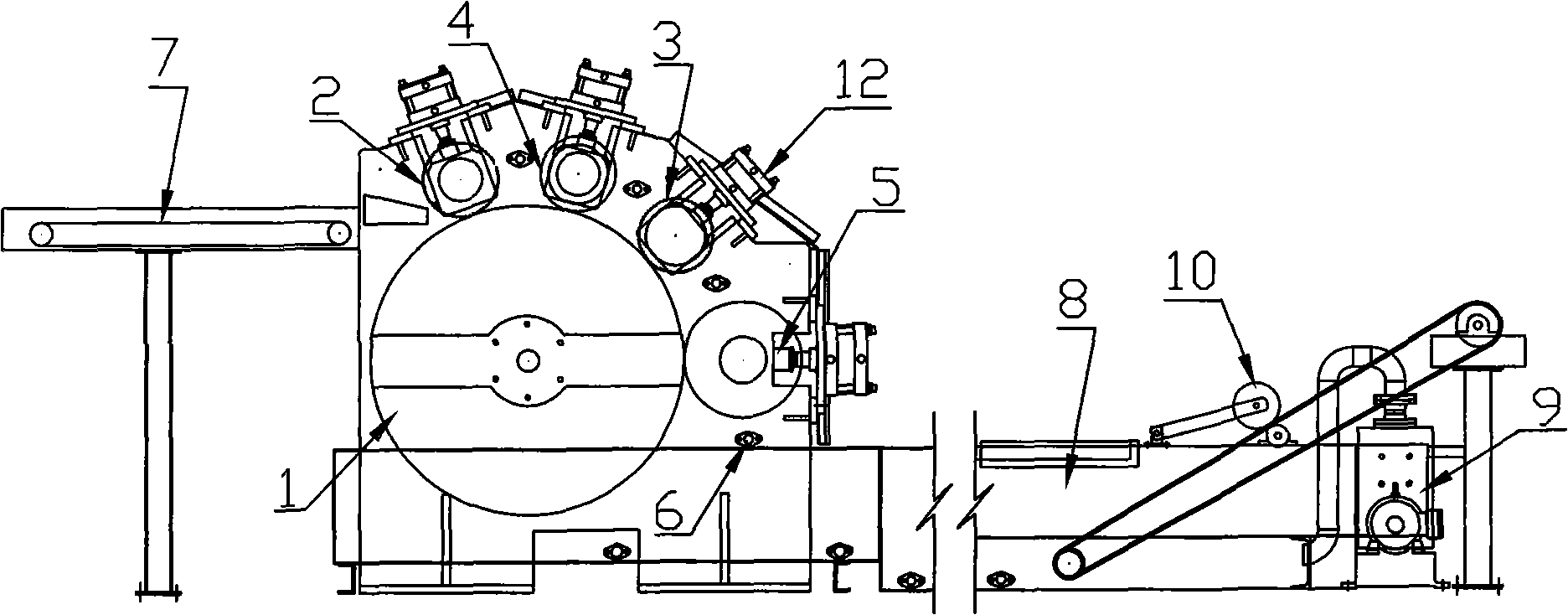

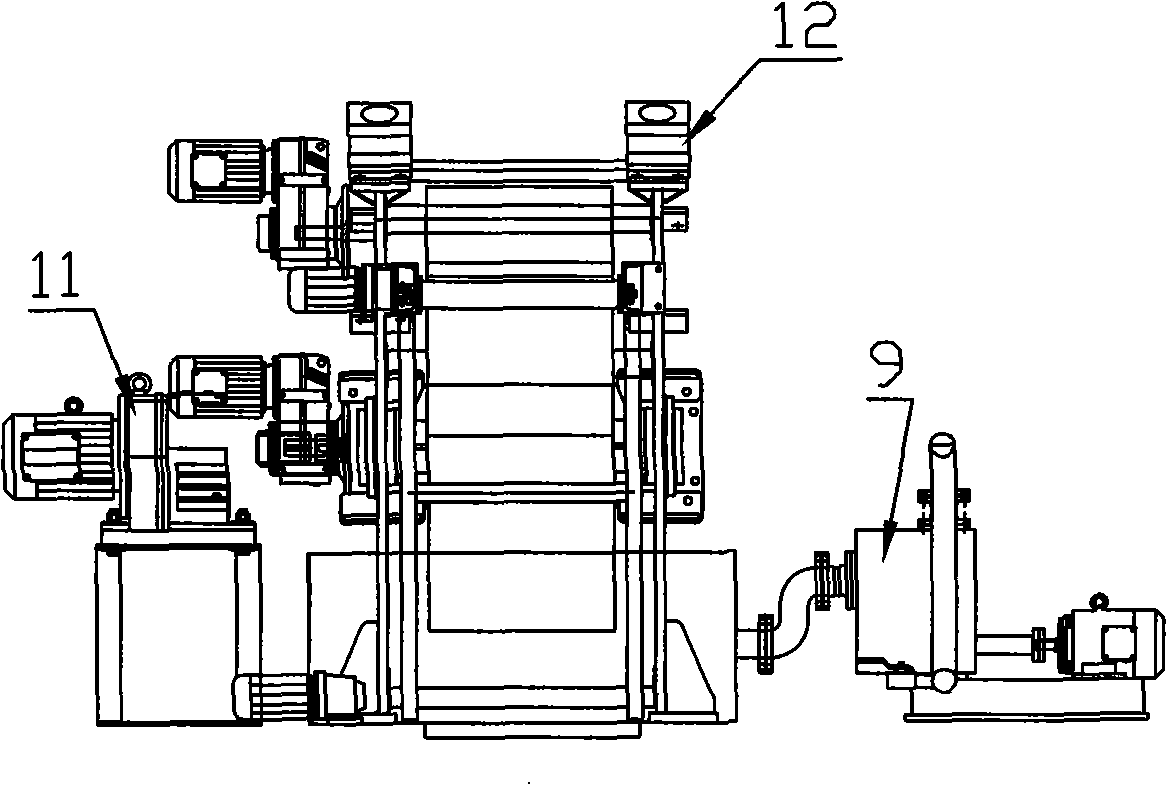

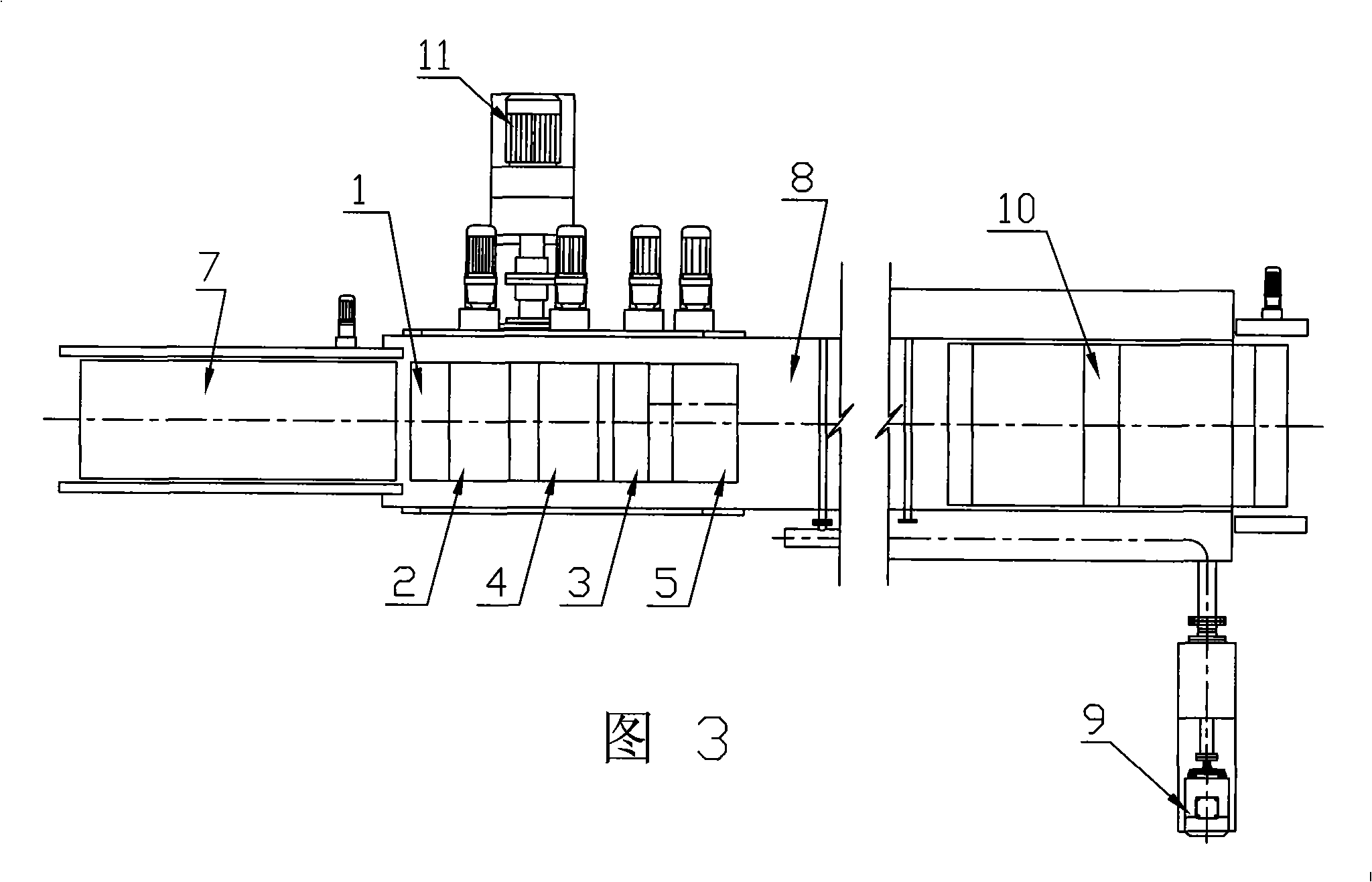

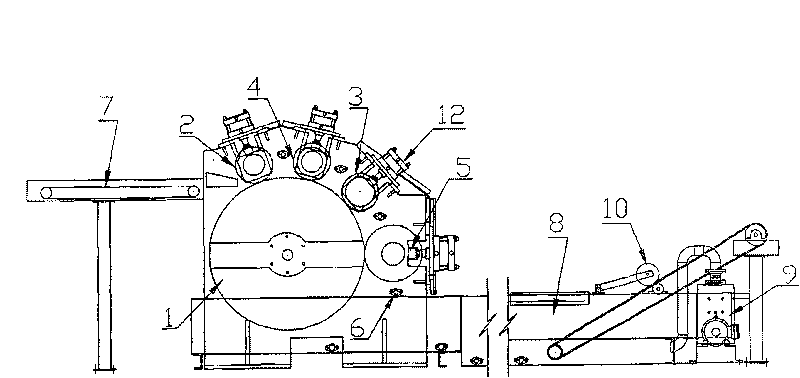

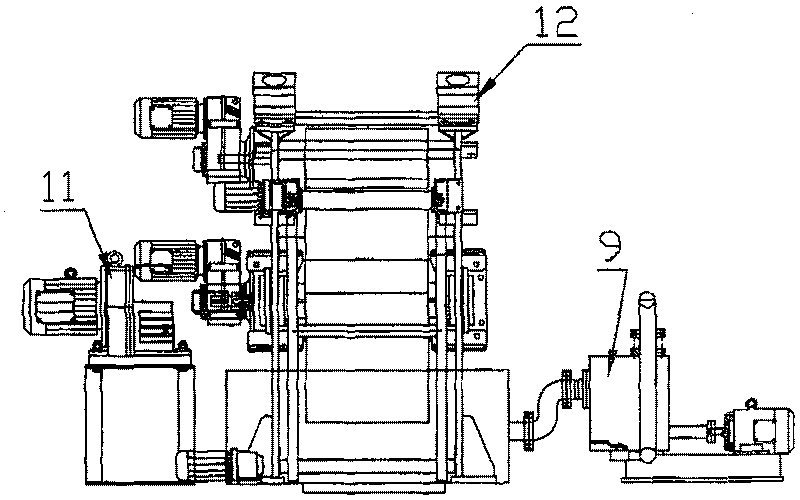

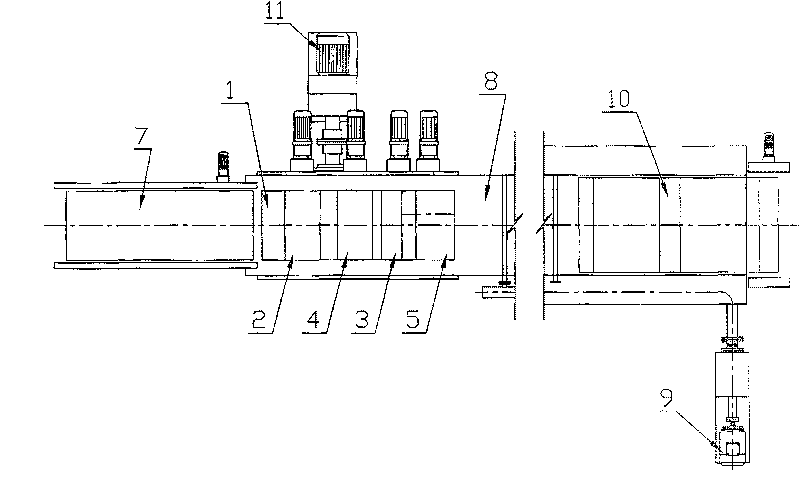

Multi-wheel scutching integrated machine of degumming and rinshing

InactiveCN101270499AHigh degree of automationSimple and fast operationMechanical fibre separationEngineeringHigh pressure water

The invention relates to a multi-gear train integral machine of scotching, degumming and washing which includes a ramie feed unit, a bone-cutting skin-scraping unit and a bone-cracking ramie-extruding unit; wherein, the bone-cutting skin-scraping unit mainly consists of a big round roll (1) and two rollers (2) and (3); the bone-cracking ramie-extruding unit mainly consists of a first small round roll (4) and a second small round roll(5). The big round roll is fixed on a frame through a bearing seat; the two rollers and the small round rolls are respectively mounted on the dump rails of each own through a sealing seat, arranged around the big round roll (1), respectively provided with a high pressure water scraper (6) which sprays water curtain along the tangent direction and opposite to the speed direction of the ramie, and the two ends of the shafts of the two rollers and the small round rolls are all provided with a pressurizing air cylinder (12). The machine finishes from ramie stalks to semi-fine dry ramie for one time and has the advantages of high automatization degree, safe use, good fiber separating effect, good ramie output, saving water, being beneficial to popularization, etc. The method can be used for processing fresh ramie so as to obtain semi-fine dry ramie.

Owner:WUHAN TEXTILE UNIV

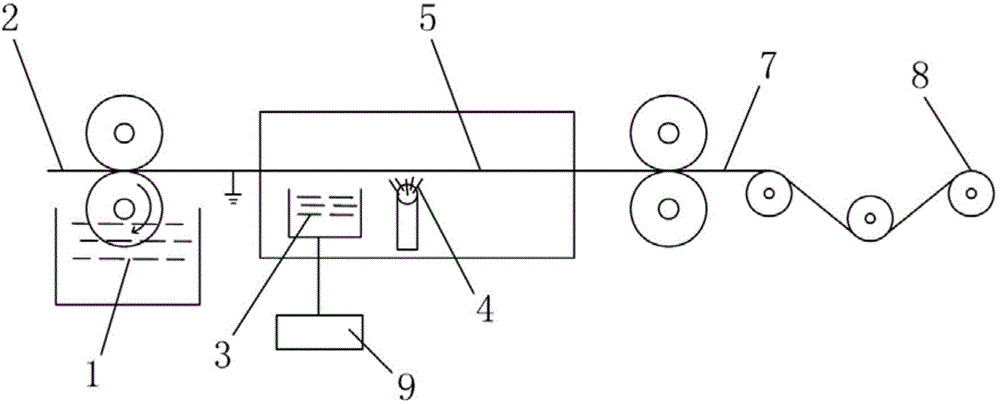

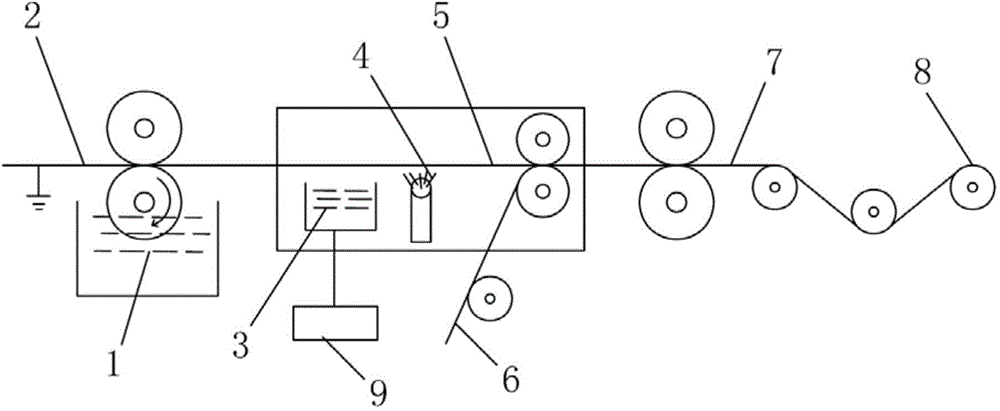

Manufacturing method of mica tape

ActiveCN102514345AReduce consumptionReduce manufacturing costLaminationLamination apparatusSolventElectric energy

The invention relates to a mica tape manufacturing method with low production cost. With the method, environment pollution is reduced. The method is suitable for energy saving and emission reduction. The method comprises the steps that: a nano-grade material processed through a surface activation treatment is added to mica powder; the nano-grade material and the mica powder are subject to high-speed stirring dispersion, and an obtained uniformly-mixed material is preserved for later use; a first adhesive is coated on a reinforcing material by using a roller; with an electrostatic field, the mica raw material is absorbed onto the reinforcing material; a second adhesive is sprayed onto the mica raw material of the reinforcing material; the one-side reinforced mica tape half-finished product is delivered through a baking oven, such that an organic solvent is removed by baking; the product is cooled, and is rolled and coiled by using a roller, such that a one-side reinforced mica tape finished product is obtained. The invention relates to a novel production technology designed according to natural characteristics of electric charges. Only a small amount of the solvent is required, such that the production cost of the mica tape is reduced, and environment pollution caused by the organic solvent is greatly reduced. Also, production speed can be improved, and baking temperature can be reduced, such that electric energy consumption can be reduced by approximately 1 / 3.

Owner:江苏冰城氢能科技有限公司

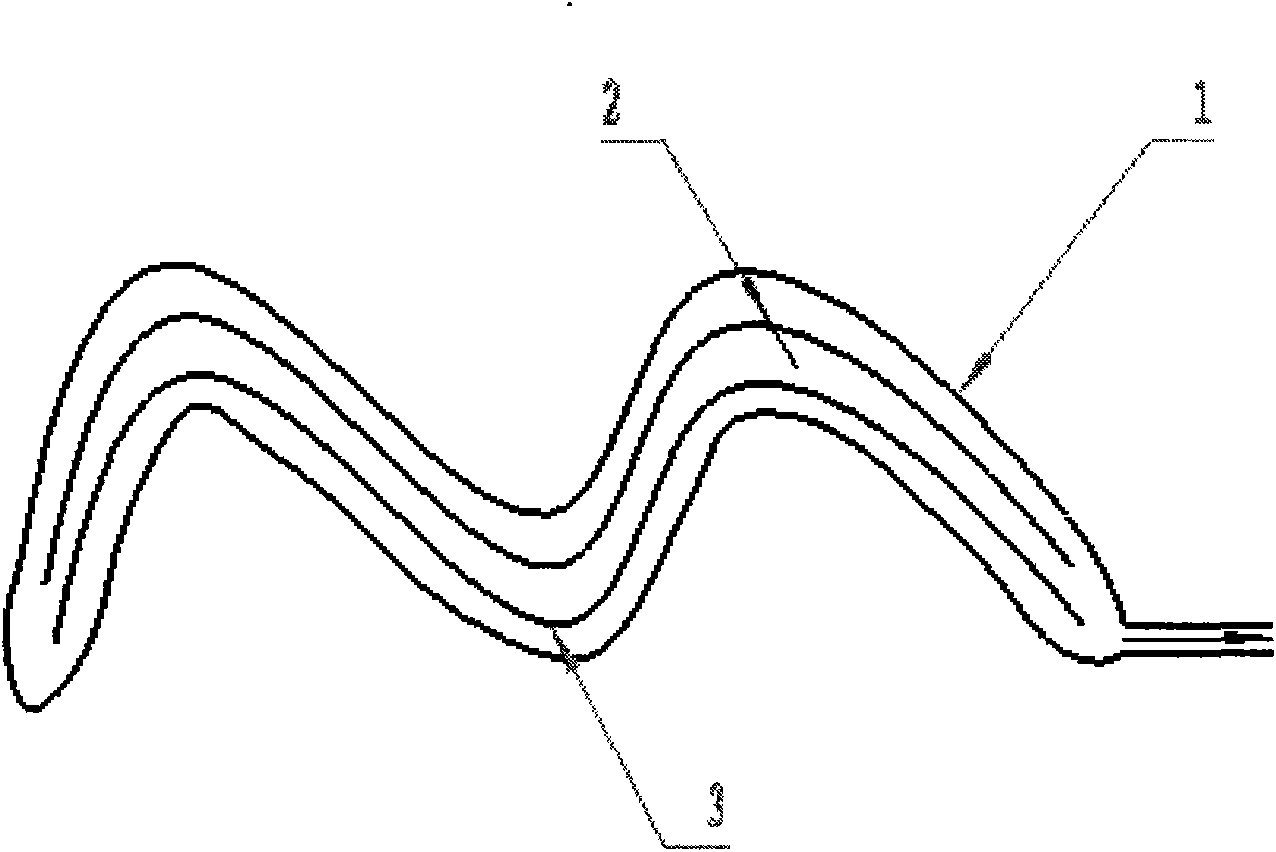

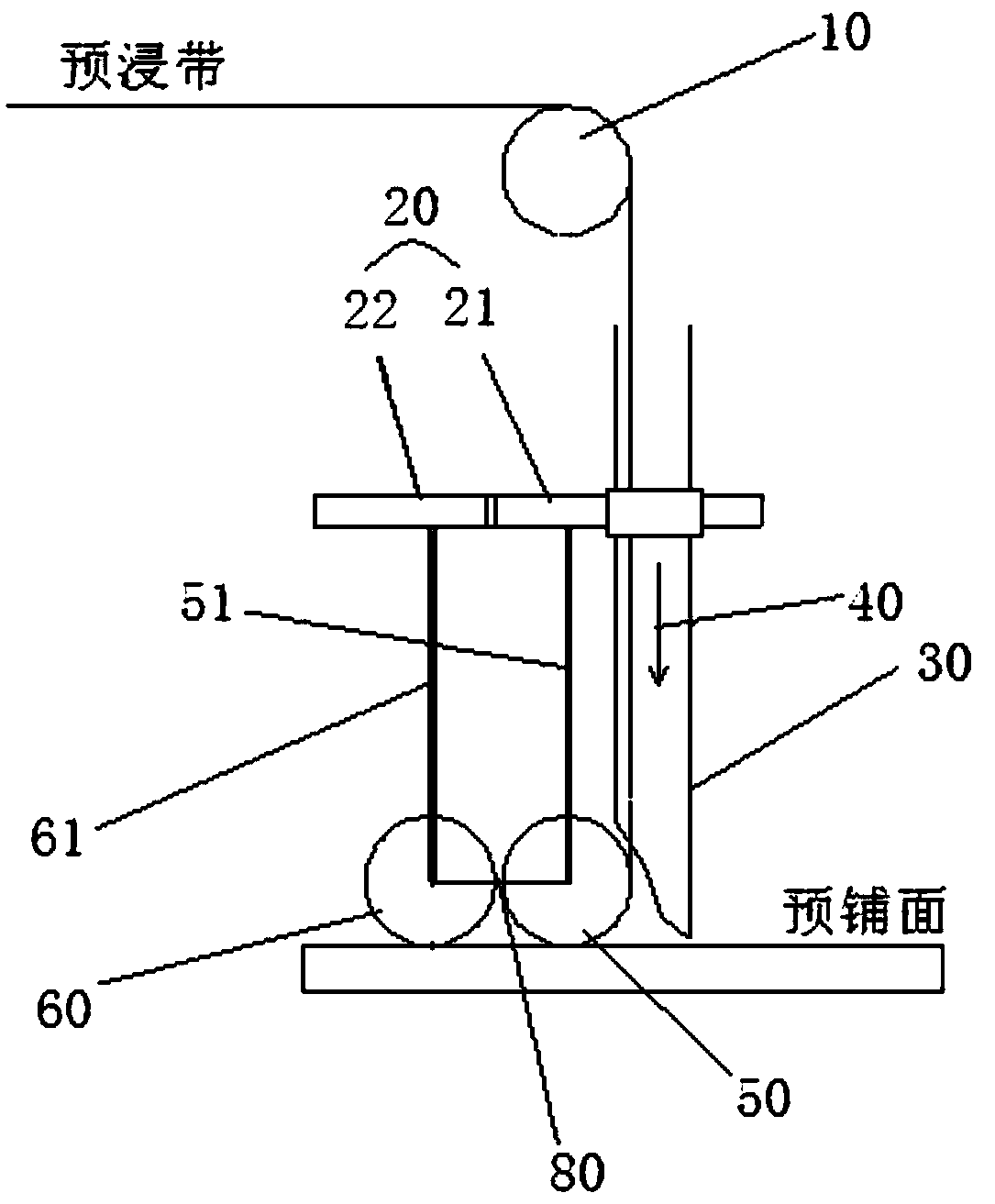

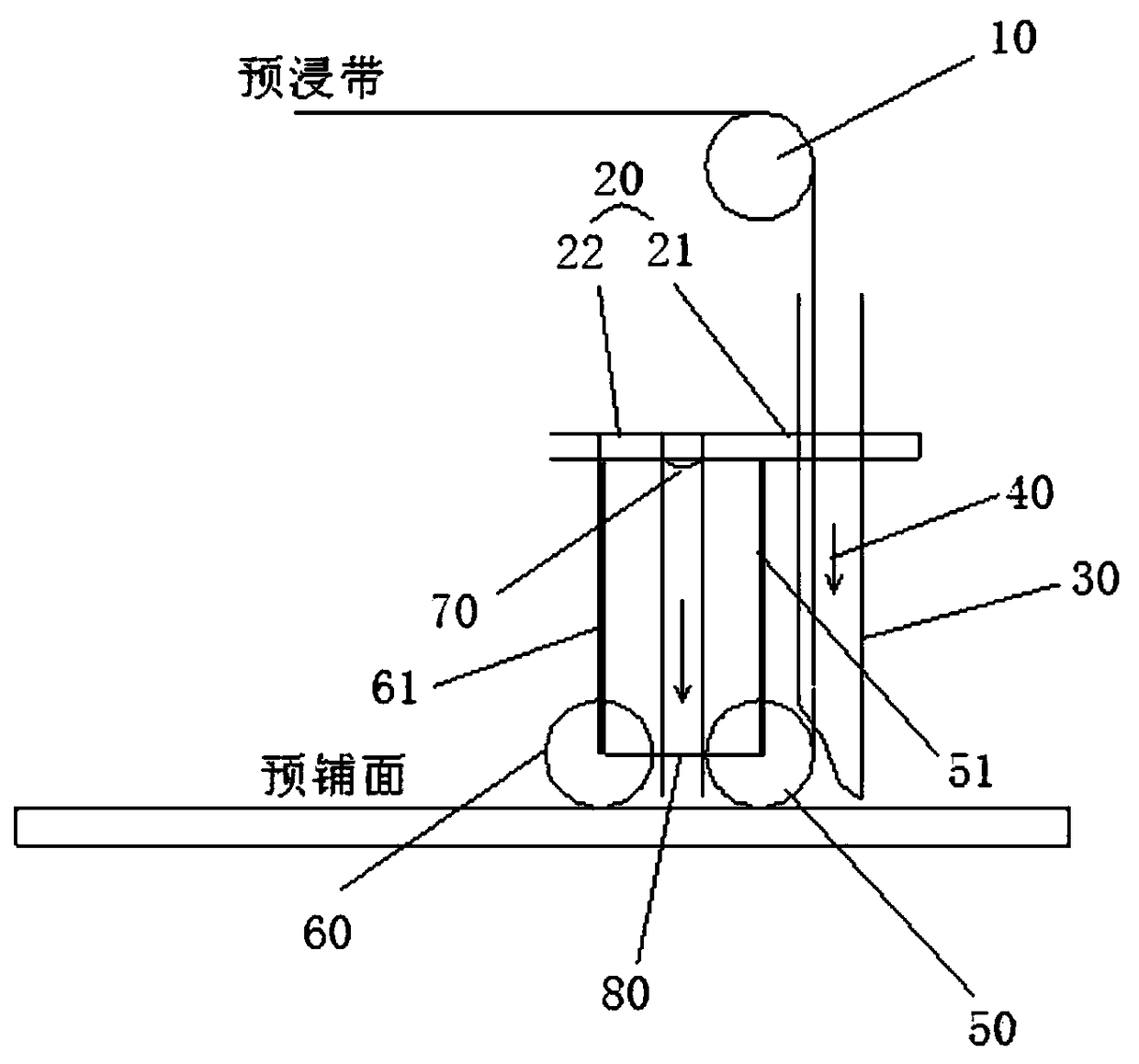

Additive manufacturing device

ActiveCN108724705AReduce gum contentOvercoming problems with additive manufacturingAdditive manufacturing apparatus3D object support structuresThermosetting polymerEngineering

The invention provides an additive manufacturing device. The additive manufacturing device comprises a movable support, a conveying roller, a transverse rod, a conveying pipe and a prepressing roller,wherein the conveying roller is fixed to the support and used for conveying a continuous fiber-reinforced thermosetting resin prepreg tape; the transverse rod is horizontally arranged on the supportand placed below the conveying roller; the conveying pipe is a pipe with the two ends open, is fixed to the transverse rod and is perpendicular to the transverse rod, and a first heat source is arranged in the conveying pipe and used for preheating the prepreg tape passing through the conveying pipe and a to-be-laid pre-laid face of the prepreg tape at the same time; and the prepressing roller isconnected with the transverse rod and is close to an opening in the lower end of the conveying pipe, and the prepressing roller presses the pre-laid face and is used for molding the preheated prepregtape onto the preheated pre-laid face. The device is applicable to additive manufacturing of continuous fiber-reinforced thermosetting prepreg, and the technical problem that in the prior art, additive manufacturing with the continuous fiber-reinforced thermosetting prepreg as a raw material is limited can be solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

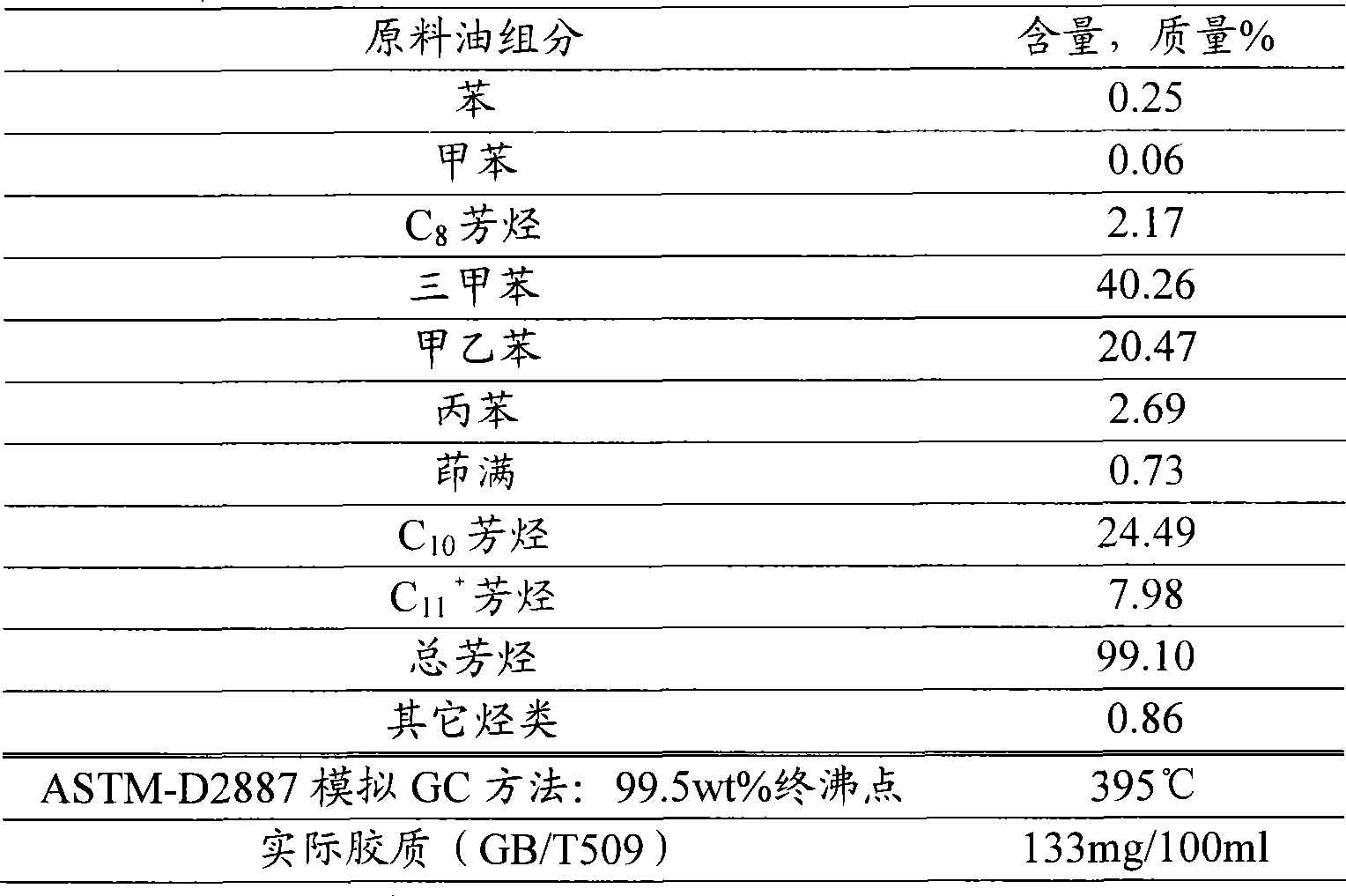

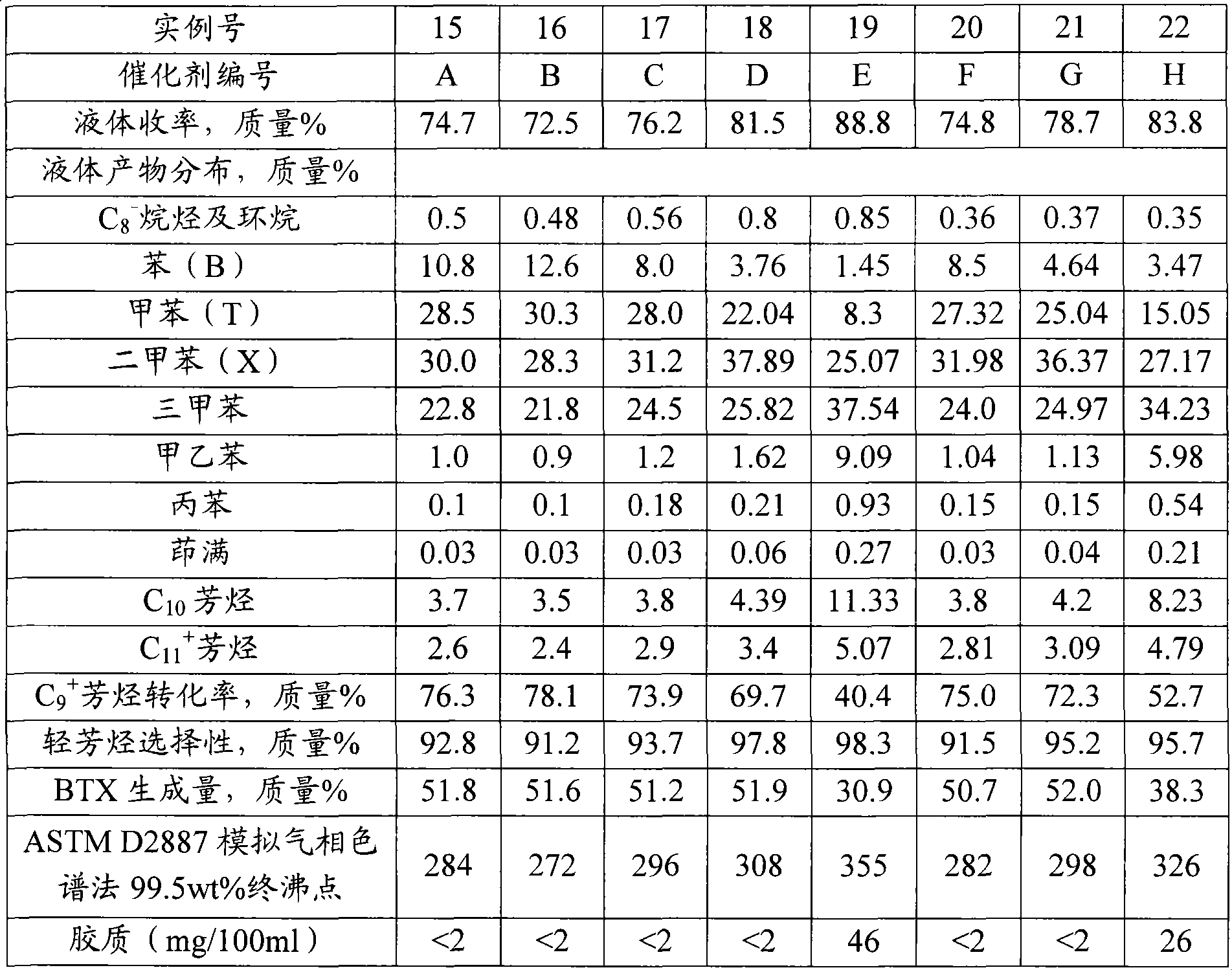

Method for conveying C<+>9 heavy aromatics to light aromatics

ActiveCN101357876AReduce carbon deposition rateImprove conversion ratePhysical/chemical process catalystsHydrocarbonsIridiumHydrogen

The invention provides a method for lightening heavy aromatic hydrocarbon C9<+>; the method comprises that the heavy aromatic hydrocarbon C9<+> is lightened by contacting and taking react with catalysts under the hydrogen with the temperature of 380 to 600 DEG C and the pressure of 0.1 to 5.0MPa. The catalysts comprise high temperature resistance inorganic oxide carriers, and 0.01 to 3.0 percent of halogen and 0.01 to 5.0 percent of iridium by mass percentage by taking carriers as calculation standards. The method is used for lightening heavy aromatic hydrocarbon C9<+>, and is characterized by high light conversion, high yield of dimethyl benzene, little carbon deposition of catalysts and effectively reducing the end boiling point and gum content of the heavy aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

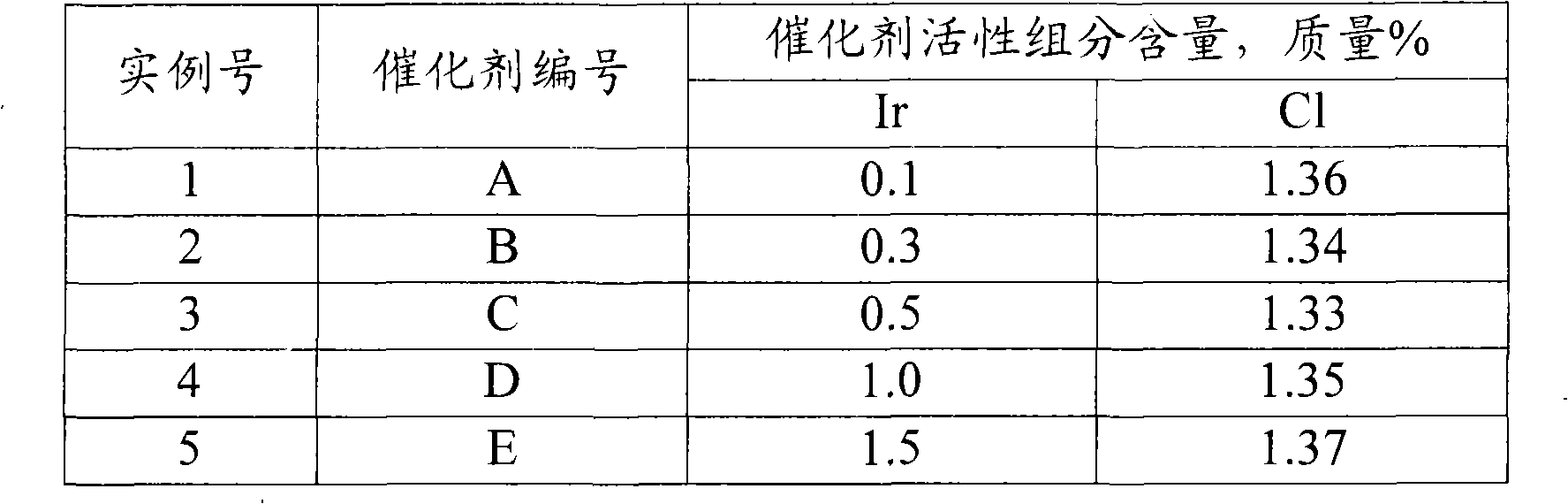

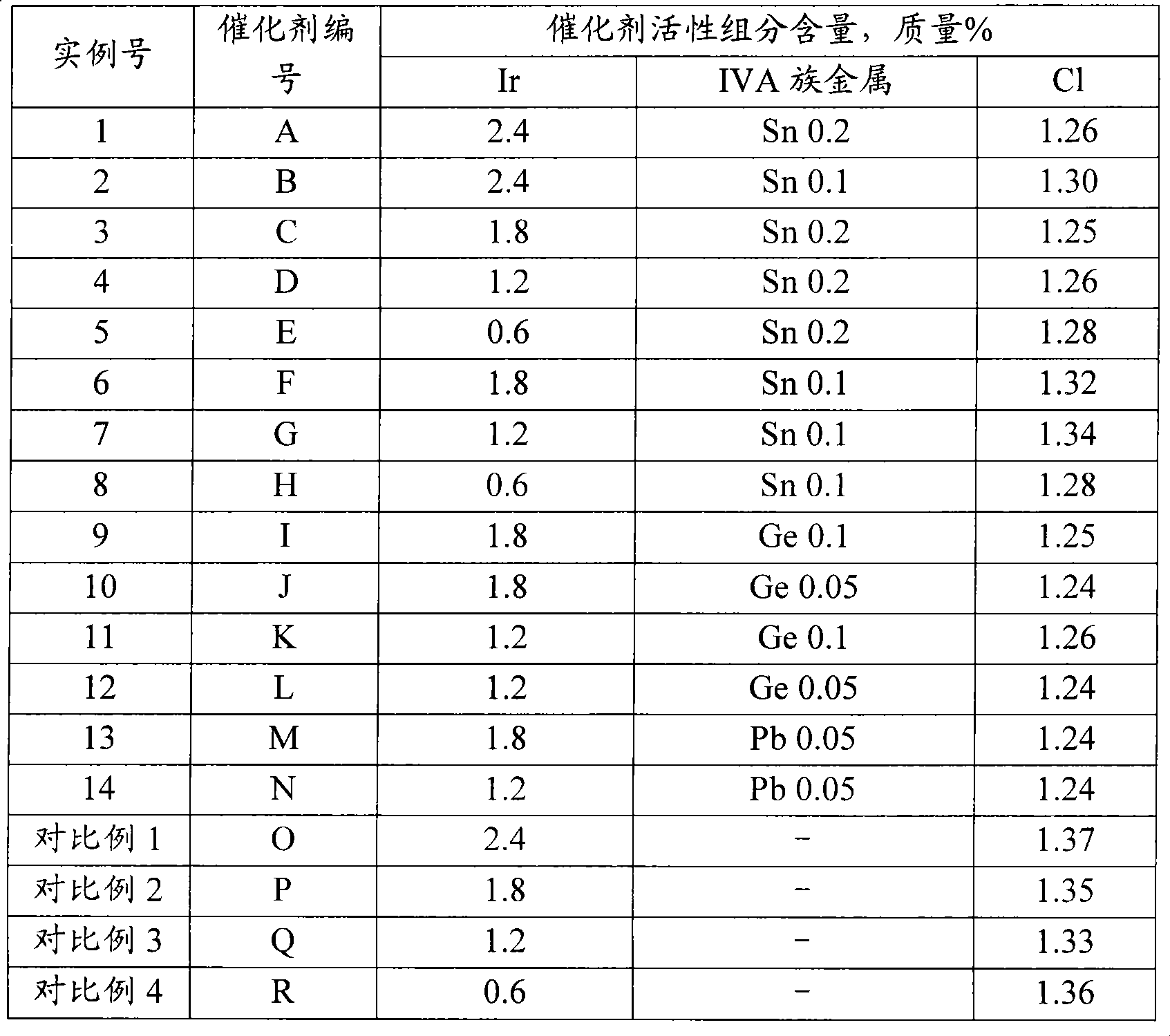

C9 aromatic hydrocarbon lightening catalyst and lightening method thereof

ActiveCN101444732AReduce carbon deposition rateImprove transformation activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsIridiumHalogen

The invention relates to a C9<+> aromatic hydrocarbon lightening catalyst, comprising a high-temperature-resistant inorganic oxide carrier and the following components accounted by taking the dry basis carrier as benchmark: 0.01-10.0 weight percent of hydrogenation metal, 0.01-1.0 weight percent of IVA-group metal and 0.1-5.0 weight percent of halogen; wherein, the hydrogenation metal is selected from iron, cobalt, nickel and iridium. The catalyst is used for lightening C9<+> heavy aromatic hydrocarbon. The catalyst has high lightening transformation ratio, high aromatic hydrocarbon yield and less carbon deposition; and the catalyst can effectively lower final boiling point and gum level of the heavy aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

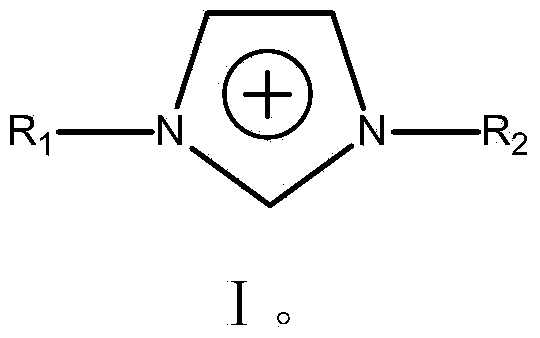

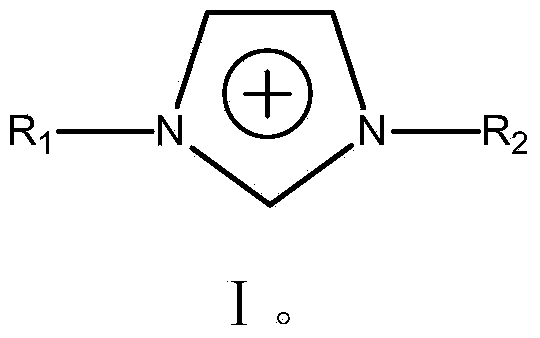

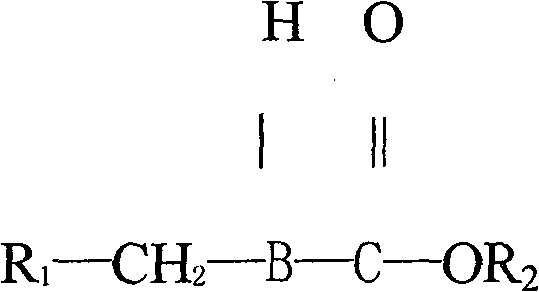

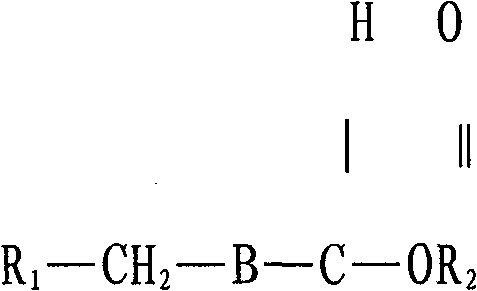

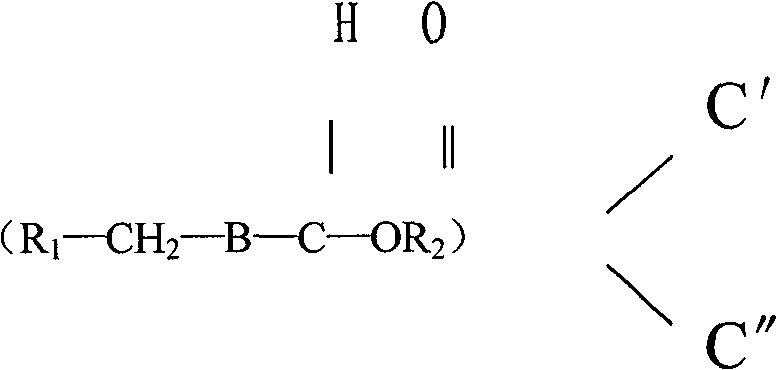

Ionic liquid-chemical combined degumming method

InactiveCN104233476ANo pollution in the processLess corrosiveFibre treatment to obtain bast fibreAlkaneColloid

The invention discloses an ionic liquid-chemical combined degumming method. The method comprises the following steps: mixing raw hemp and water and boiling the mixture with water first, then mixing the dried boiled mixture and an ionic liquid aqueous solution, and performing stirring treatment for 2 to 4 hours at the temperature of 40 to 120 DEG C; filtering and separating the mixture, washing the obtained solid with clean water, and drying; performing chemical degumming treatment on the obtained solid, wherein the ionic liquid is of an A<+>B<-> structure, the cation A<+> is of the structure shown in the general formula I, R1 and R2 in the general formula are respectively and independently selected from alkane or alkene of C1 to C5; the anion B<-> is acetate. According to the ionic liquid-chemical combined degumming method, pretreatment is performed through ionic liquid; the hemp degumming pretreatment effect is good; the colloid content of the raw hemp can be effectively reduced; after the pretreatment, the colloid in hemp can be reduced by about 20 percent; subsequent degumming treatment of hemp fibers is facilitated; the damage to the raw hemp is low; ionic liquid degumming and chemical degumming are performed in a combined manner, so that degummed hemp fibers with higher performance can be obtained, and the environment pollution can be reduced.

Owner:DALIAN POLYTECHNIC UNIVERSITY

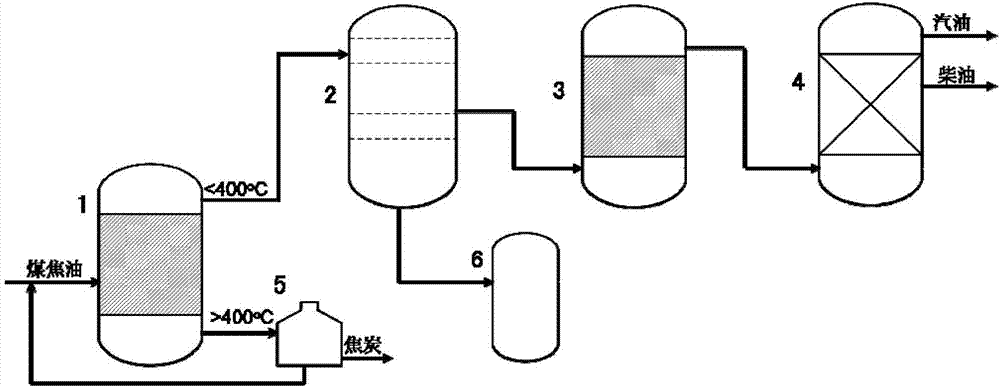

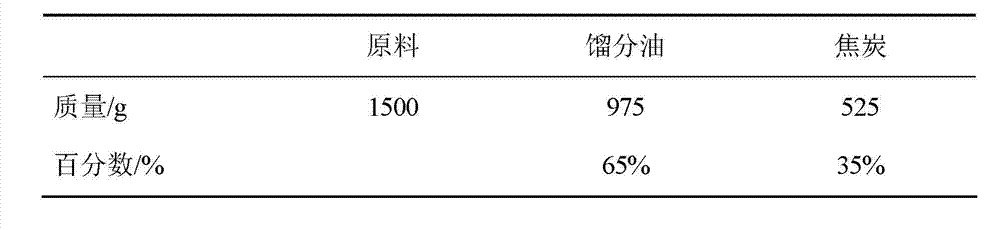

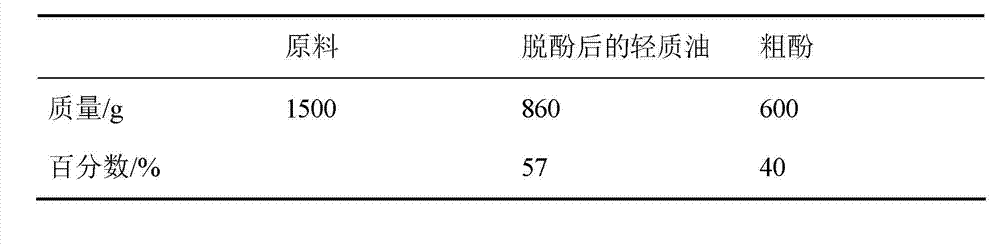

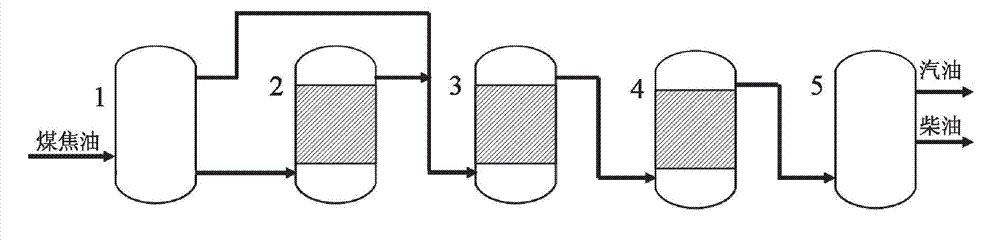

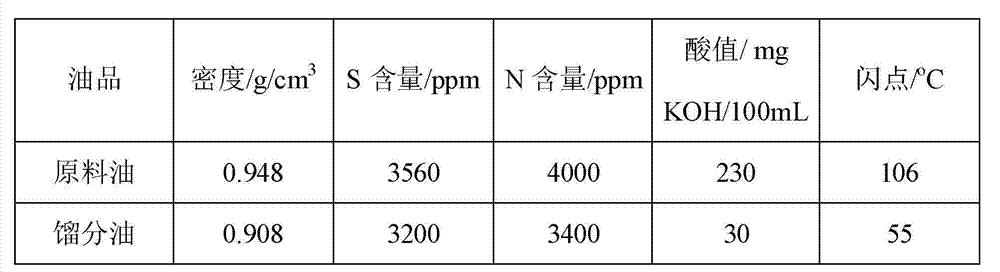

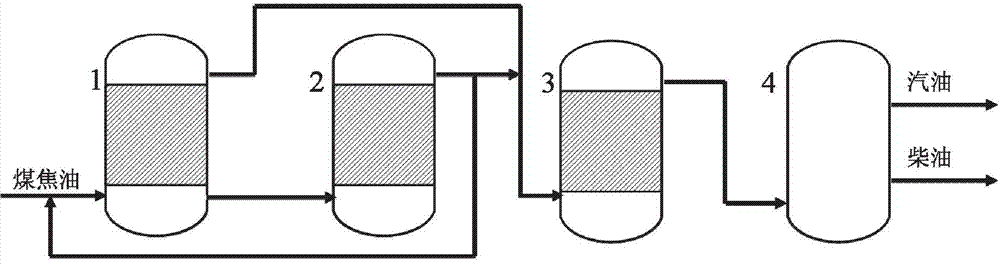

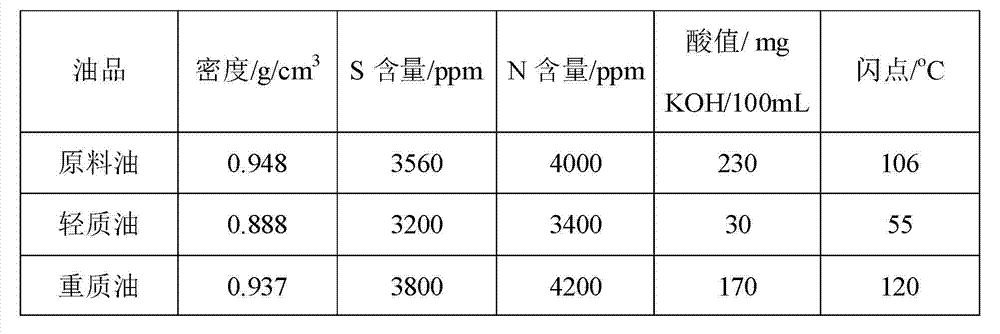

Method for improving hydrogenation production of gasoline and diesel oil by coal tar

InactiveCN102876376AReduce yieldDelayed cokingChemical industryTreatment with hydrotreatment processesFractionationCatalytic distillation

The invention discloses a method for improving hydrogenation production of gasoline and diesel oil by coal tar, and belongs to the fields of coal chemical industry and energy technology. The invention is characterized in that the method comprises the following steps: distilling coal tar for separation to obtain light oil (360 DEG C) and heavy oil (360 DEG C), performing delayed coking of the heavy oil, mixing with the light oil, adding the mixed oil into a reaction distillation tower for catalytic cracking and fractionation, introducing the oil gas after catalytic cracking into a hydrogenation reaction tower for hydrorefining, distilling the reaction product to obtain high-quality distillate of gasoline and diesel oil. A catalytic distillation catalyst and a sulfide catalyst used in the invention are prepared by appropriate carriers and active components through a liquid phase method, wherein the appropriate carriers and active components are selected base on the composition and performance of the coal tar. The method of the invention is simple in process, high in catalyst activity and selectivity, low in residual charcoal, and high in gasoline and diesel oil yield, provides a new approach for the utilization of coal tar, and has good economic benefits and industrial application prospects.

Owner:DALIAN UNIV OF TECH

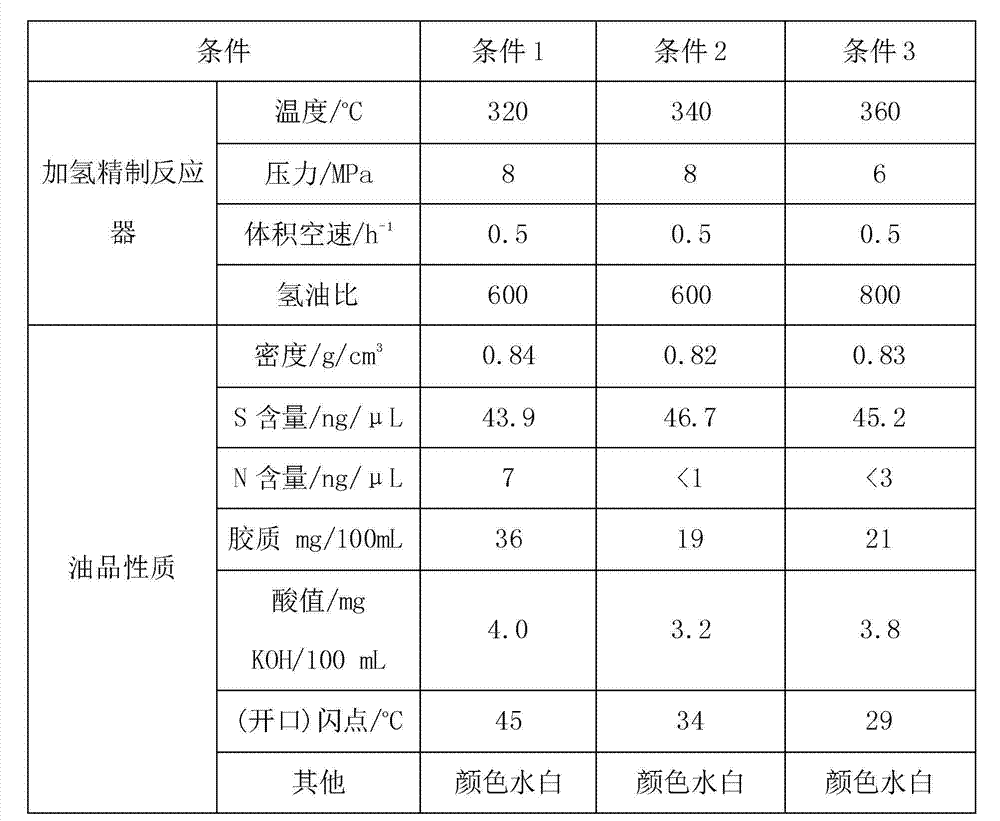

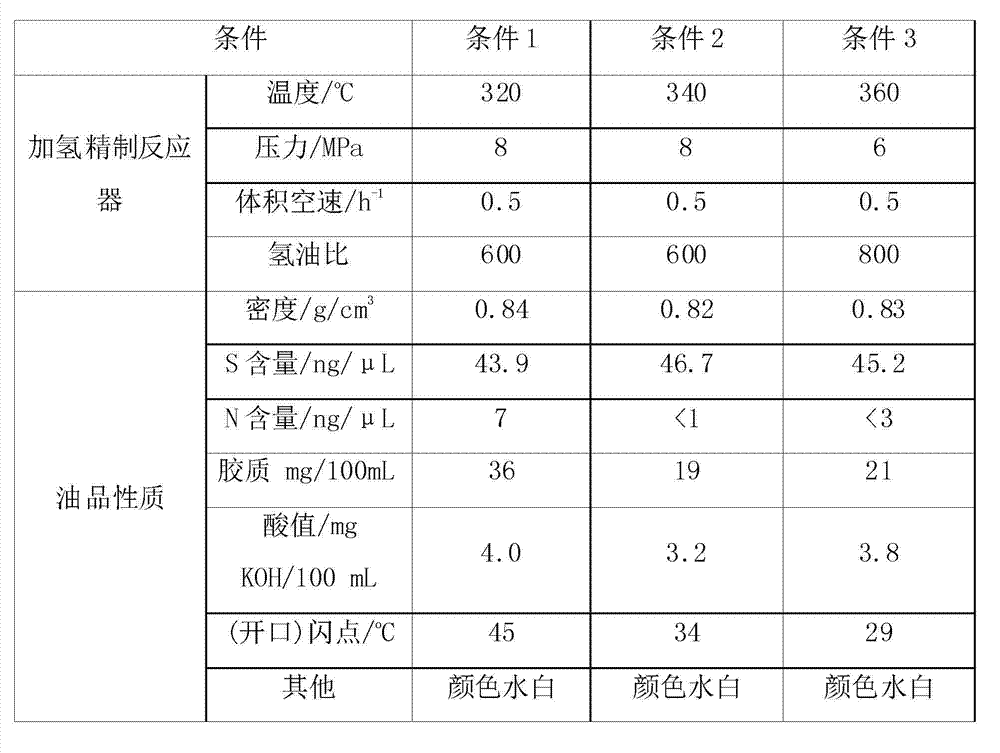

Coal tar hydrogenation upgrading method

InactiveCN102863986AHigh yieldImprove conversion rateChemical industryTreatment with hydrotreatment processesSulfideCatalytic distillation

The invention discloses a coal tar hydrogenation upgrading method belonging to the technical fields of coal chemical industry and energy. The coal tar hydrogenation upgrading method is characterized by comprising the following steps: performing catalytic distillation cracking on coal tar, and then dividing into light oil and heavy oil; performing delayed coking on the heavy oil, and then performing further catalytic distillation on the heavy oil mixed with the coal tar or hydrofining the heavy oil together with the light oil; and distilling the reaction product to obtain high-grade gasoline and diesel distillate oil. A catalytic distillation catalyst and a sulfide catalyst used in the method are prepared by selecting appropriate carriers and active components through a liquid phase method according to the composition and property of the coal tar. The invention has the advantages of simple process, high catalyst activity and selectivity and high gasoline and diesel yield, provides a new way for the utilization of the coal tar, and has favorable economic benefits and industrial application prospects.

Owner:DALIAN UNIV OF TECH

Nonmetallic gasoline additive and method for preparing same

ActiveCN107916147ASimple stepsSave raw materials and energy consumptionLiquid carbonaceous fuelsFuel additivesNitrogen oxidesNOx

The invention discloses a nonmetallic gasoline additive and a method for preparing the same. The nonmetallic gasoline additive comprises, by weight, 0.5-12% of polyether, 0.5-12% of polyether polyol,0.5-10% of poly-alcohol, 0.1-15% of catalysts, 0.1-15% of stabilizers, 1-16% of soluble silicic acid and 55.9-92% of polyol. The method includes adding the polyether, the polyether polyol, the poly-alcohol and the catalysts into the polyol; carrying out stirring reaction to obtain transparent oily liquid; adding the soluble silicic acid into the liquid; carrying out stirring reaction at the temperature of 80-110 DEG C until solution turns clear; filtering the clear solution to obtain the nonmetallic gasoline additive. The nonmetallic gasoline additive and the method have the advantages that more than 18% of gasoline can be saved by the aid of the nonmetallic gasoline additive under identical conditions, emission of hydrocarbon HC, carbon monoxide CO, PM (particulate matters) and nitrogen oxide NOx can be reduced to a great extent, the smoke intensity can be lowered to a great extent, and effects of inhibiting carbon deposit generation and eliminating carbon deposits can be realized; the nonmetallic gasoline additive is stable in property, can be safely stored and transported and is free of damage to gasoline cylinders and engines, the nonmetallic gasoline additive and gasoline arecompletely mutually soluble, precipitation and layering can be prevented.

Owner:保定市瑞方生物科技有限公司

Nitrile rubber protective sleeve

InactiveCN102070800AReduce dosageImprove adaptabilityOther chemical processesStearic acidTemperature resistance

The invention belongs to the field of sealing materials, in particular to a nitrile rubber protective sleeve, which comprises the following ingredients in parts by weight: 20 to 30 parts of nitrile rubber, 2 to 8 parts of calcined clay, 6 to 10 parts of talcum powder, 1 to 4 parts of chlorcosane, 0.01 to 0.04 part of phthalocyanine blue, 0.5 to 3 parts of zinc oxide, 0.1 to 0.5 part of age inhibitors RD, 0.1 to 0.4 part of age inhibitors H, 0.2 to 0.6 part of stearic acid, 0.5 to 2 parts of coumarone, 8 to 12 parts of white carbon black, 1 to 4 parts of di octyl phthalate (DOP) softening agents, 0.5 to 1.2 parts of accelerators DM, 0.2 to 0.8 part of accelerator tetramethylthiuram disulfide (TMTD) and 0.1 to 0.3 part of sulphur. The nitrile rubber protective sleeve adopting the recipe has the advantages that the physical and mechanical performance of the nitrile rubber protective sleeve are not reduced, but the cost is greatly reduced, the surface smoothness of products and each applicability of an oil well are also greatly improved, and the properties such as acid resistance, base resistance, oil resistance, temperature resistance, wear resistance, flame retardance and the like of the products are also greatly improved.

Owner:山东宝世达电缆有限公司

Formula and preparation method of lead-carbon colloid battery electrode plate lead paste

ActiveCN106169565AImproved fast charging capabilityImprove power densityLead-acid accumulatorsCell electrodesPorosityCellulose

The invention provides a formula and a preparation method of a lead-carbon colloid battery electrode plate lead paste. According to the present invention, partial lead is replaced by Cypbrid carbon, such that the battery has characteristics of the lead acid battery and the capacitor with the adding of the Cypbrid carbon so as to easily improve the rapid charging capacity of the battery, increase the power density of the battery and prolong the cycle life, and the Cypbrid carbon occupies the partial electrode space so as to cause the reducing of the energy density and increase the gassing amount of the electrode; SiO2 and polyanionic cellulose are added, such that the electrode plate porosity is increased, the adsorption of sulfuric acid is increased, and the protection effect is provided for the active substance attached on the surface of the electrode plate; the colloid exists in the dry paste of the electrode plate so as to increase the sulfuric acid and water retention capacity and provide the excellent charge and discharge characteristics, and can be matched with the colloidal electrolyte, such that the colloid content in the acid injection liquid can be reduced, the uniform distribution of the filled colloid is easily achieved, and the electrolyte in the separation plate and the colloid can be organically combined in the electrode plate.

Owner:HUBEI RUNYANG NEW ENERGY

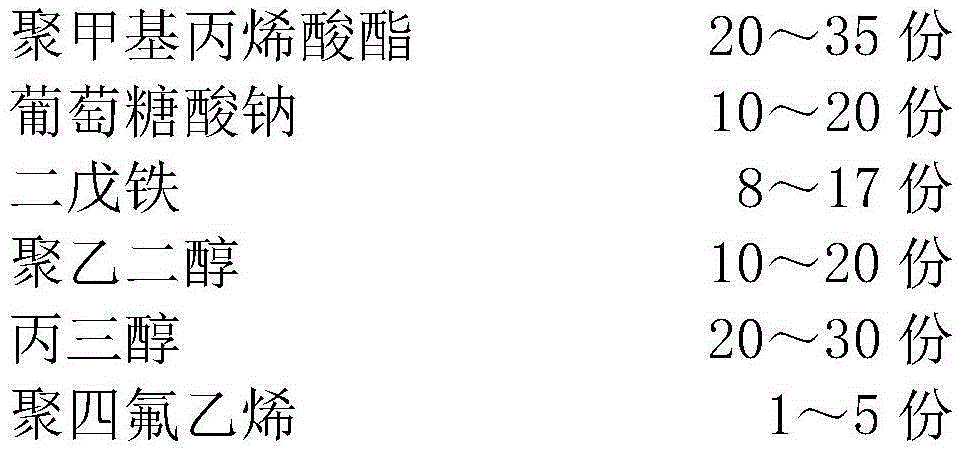

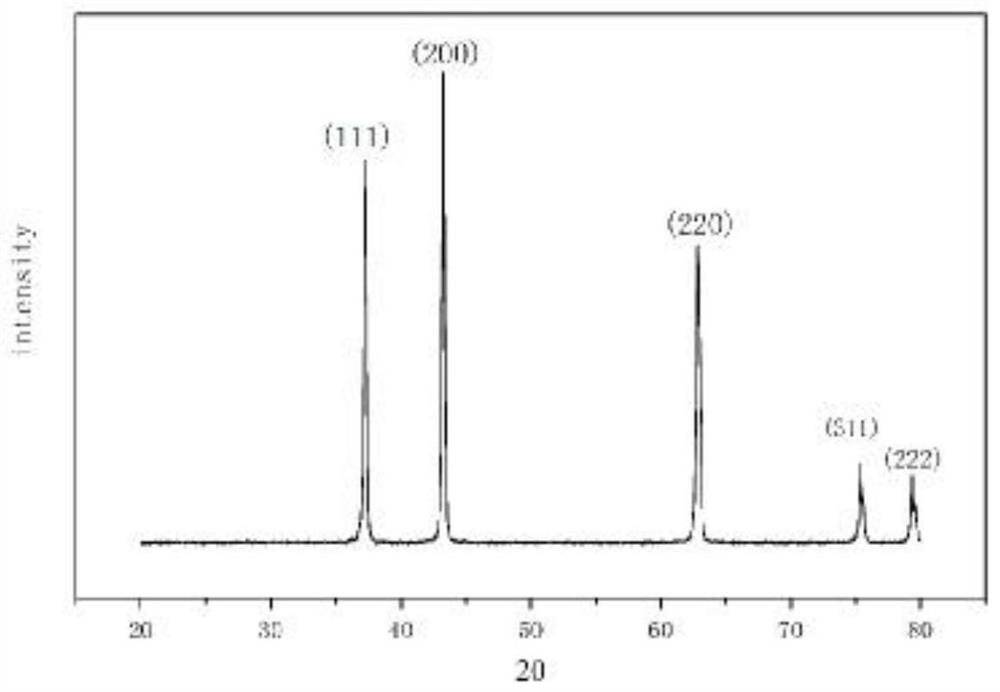

Smoke-eliminating antifreezing agent for diesel oil

InactiveCN104910978ANot easy to grow upInhibit growthLiquid carbonaceous fuelsFuel additivesPolyethylene glycolGlycerol

The invention relates to the technical field of petrochemical engineering, and particularly relates to a smoke-eliminating antifreezing agent for diesel oil. The antifreezing agent is prepared from the following raw materials in parts by weight: 20-35 parts of polymethacrylate, 10-20 parts of sodium gluconate, 8-17 parts of Fe(C5H5)2, 10-20 parts of polyethylene glycol, 20-30 parts of glycerol, 1-5 parts of polytetrafluoroethylene, and 10-18 parts of alkyl glycoside. The smoke-eliminating antifreezing agent for diesel oil disclosed by the invention can keep continuously supplemental firing, and can significantly reduce the condensation point and cold filter plugging point of diesel oil, prevent the diesel oil from being frozen at low temperature, clean parts, improve the effect of smoke elimination, and reduce the emission of exhaust gas.

Owner:ZHONGZHOU UNIV

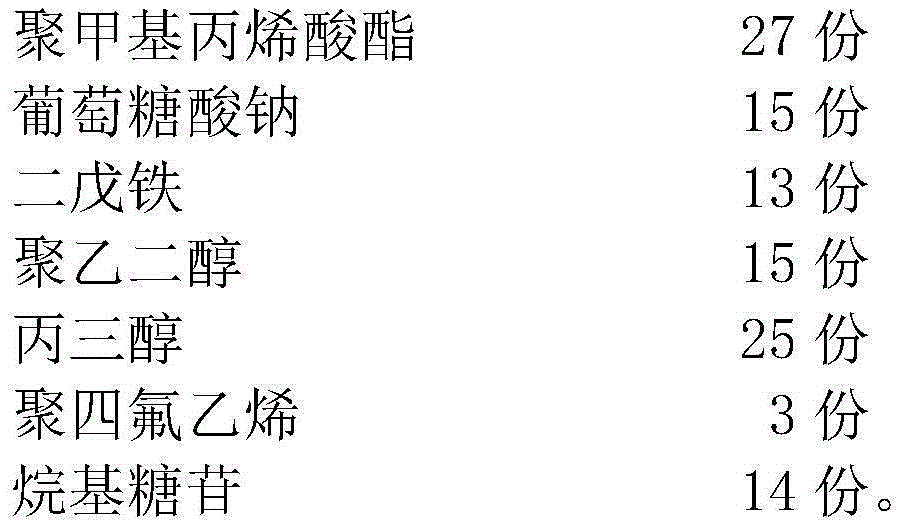

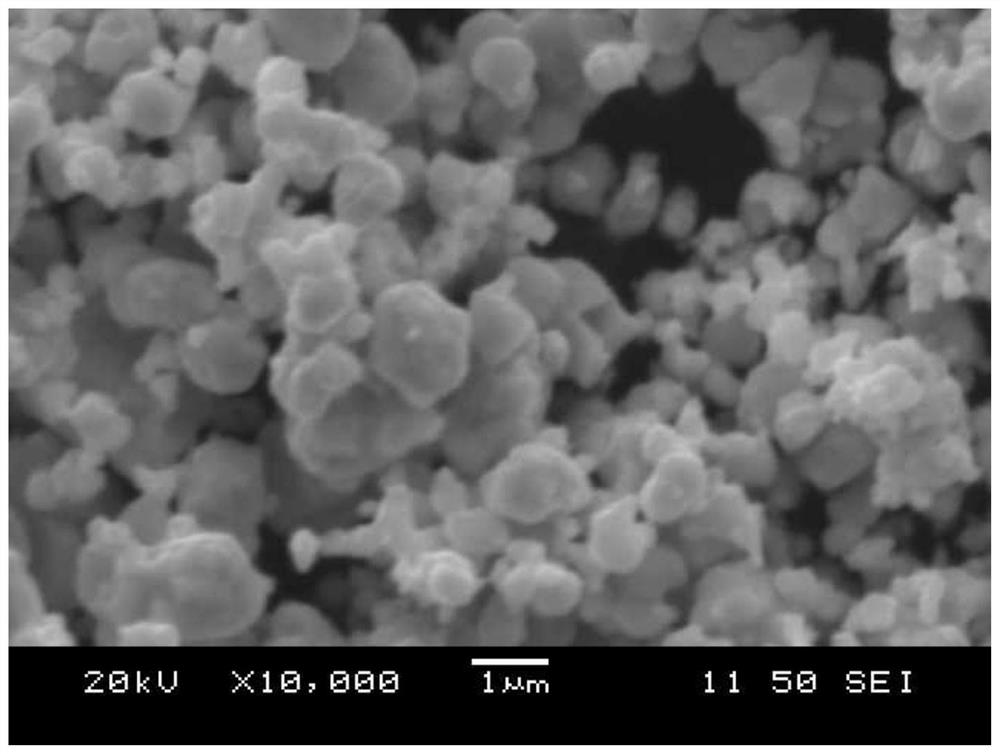

Cold isostatic pressing forming preparation method of nickel oxide-based ceramic target material

InactiveCN112456971AImprove conductivityHigh densityVacuum evaporation coatingSputtering coatingSpray driedMass fraction

The invention relates to a cold isostatic pressing forming preparation method of a nickel oxide-based ceramic target material, wherein the method comprises the following steps: A, preparing raw materials: preparing mixed powder of nickel oxide powder and doped source powder, wherein the total mass fraction of doped source elements in the mixed powder is not more than 10%, wherein the doping sourceelement is selected from one or more of 0-6% of Li, 0-0.3% of Na, 0-1.0% of Mg, 0-0.1% of Al, 0-0.1% of Si, 0-0.15% of K, 0-12% of Zn, 0-1.5% of Zr, 0-1.2% of Mn, 0-10% of Cu, 0-1.2% of Cr, 0-0.3% ofV, 0-10% of W and 0-2.5% of Ti; B, carrying out spray drying; C, compacting by vibration; D, feeding a mold into a cold isostatic pressing chamber for pressing; E, degumming a biscuit; F, sintering;G, cooling after heat preservation is finished; and H, machining or not machining according to needs. The preparation method can be used for preparing the nickel oxide-based ceramic which is good in conductivity, relatively high in purity and fine in grain size.

Owner:北京航大微纳科技有限公司

Eucommia seed oil refining technology

ActiveCN103113983AReduce gum contentReduce wax contentFatty-oils/fats refiningChemical reactionOil quality

The invention belongs to the field of oil refining technology, and particularly relates to a eucommia seed oil refining technology which comprises the following steps of: washing the crude eucommia seed oil; dehydrating and decoloring; performing deacidification and deodorization at the same time after the decoloring; and finally performing polishing treatment. According to the invention, deacidification and deodorization are performed at the same time, and physical operation is adopted to avoid chemical reaction and high-temperature operation, thereby greatly improving the oil quality.

Owner:LINGBAO JINDI EUCOMMIA IND

Mica tape manufacturing method suitable for energy conservation, emission reduction and reduction of environmental pollution

InactiveCN104409187AReduced insulation performanceReduce manufacturing costLaminationLamination apparatusOrganic solventAdhesive

The invention relates to a mica tape manufacturing method suitable for energy conservation, emission reduction and reduction of environmental pollution. The mica tape manufacturing method includes adding nanometer materials subjected to surface activation into mica powder; uniformly stirring and dispersing the nanometer materials and the mica powder at high speed for standby application; coating first adhesive on a reinforced material through a drum, and adsorbing mica raw materials onto the reinforced material by means of an electrostatic field; spraying second adhesive onto the mica raw materials on the reinforced material, compositing the second layer of a reinforced material to obtain a semi-finished double-side reinforced mica tape; drying the semi-finished double-side reinforced mica tape to remove organic solvent through a drying oven, cooling and rolling the semi-finished double-side reinforced mica tape to obtain a mica roll, namely a finished double-side reinforced mica tape. The mica tape manufacturing method is a new production process utilizing natural characteristics of charge. Only by little solvent, production cost of the mica tape is reduced, and the environmental pollution of the organic solvent is greatly reduced.

Owner:JIANGSU ICE CITY INSULATION MATERIALS STOCK

Preparation method for thermal expansion glass felt

ActiveCN109183269AReduce gum contentHigh expansion rateNon-woven fabricsGlass fiberThermal expansion

The invention belongs to the technical field of electrical insulating materials, and specifically relates to a preparation method of thermal expansion glass felt. The method comprises the steps of carrying out glue dipping, glue extruding, drying and clipping on glass fiber felt, wherein the glass fiber felt is single-layer needled glass fiber felt, and the thickness is 8-20mm. According to the thermal expansion glass felt provided by the invention, firstly glass fibers are manufactured into soft needled glass felt in the form of needling, and then the glass felt is subjected to the processessuch as glue dipping and glue extruding, so that multi-layer superposition is not required, and the preparation process is simplified. In addition, the thickness of the glass fiber felt is improved, the glue content of the glass felt is reduced, the expansion rate of the expansion felt is improved, and thus the paint absorbing amount after paint dipping is improved.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Method for preparing air-tight promoter

The invention relates to a method for preparing a promoter, in particular to a method for preparing an air-tight promoter. The method for preparing the air-tight promoter is characterized by comprising the following steps of: 1, adding short fibers, asphalt, silicon and alumina powder into coal powder, proportioning and mixing, wherein the adding amount of the short fibers is in an amount which is 15 percent based on the input amount of materials; 2, adding a mixture which is metered and mixed in the step 1 into a pulverizing mill for grinding, and performing vibration sieving purification by using a screen sieve; and 3, adding treated distillate aromatic extract (TDAE) into the mixture obtained in the step 2, putting into a mixing machine at the temperature of between 40 and 45 DEG C, rotating and mixing for 1 to 10 minutes, and discharging. The method has the advantages that: the content of rubber in butyl rubber is reduced, specific gravity is low, Mooney viscosity is reduced, and extrusion rate is improved, so that the production speed and the production efficiency of a product are increased; and return rate is reduced, namely product yield is improved.

Owner:山东迪科化学科技股份有限公司

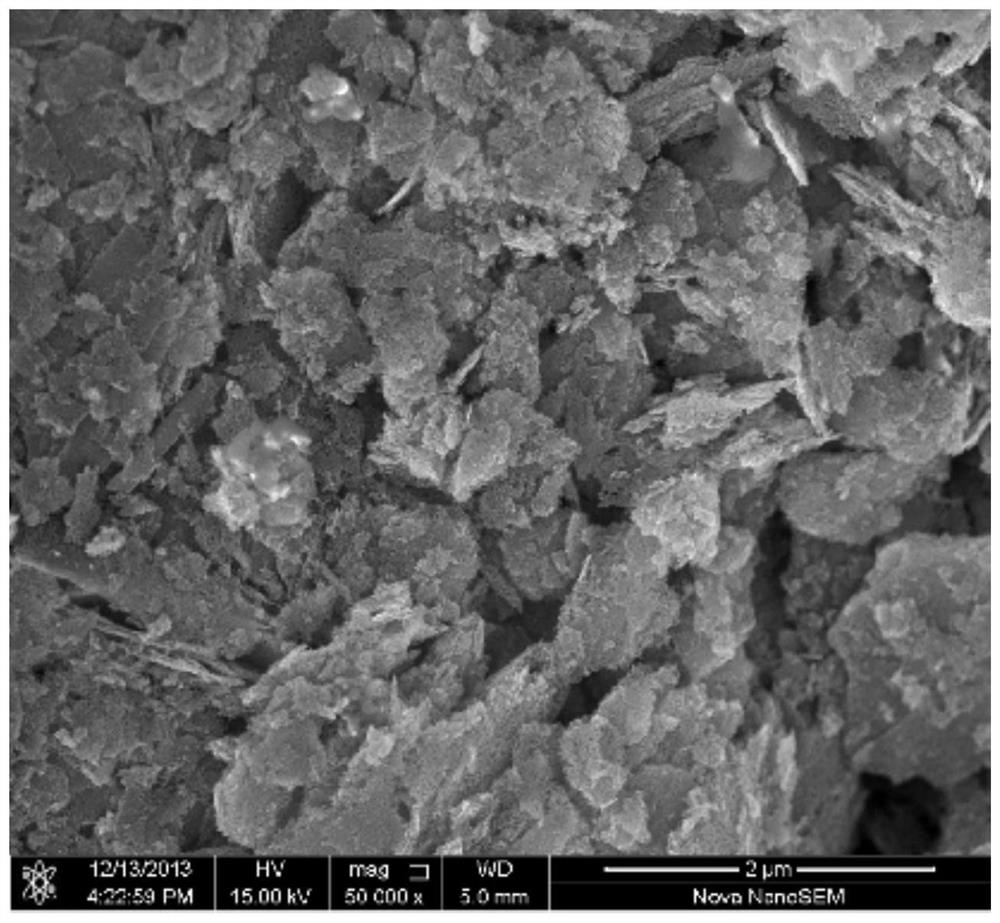

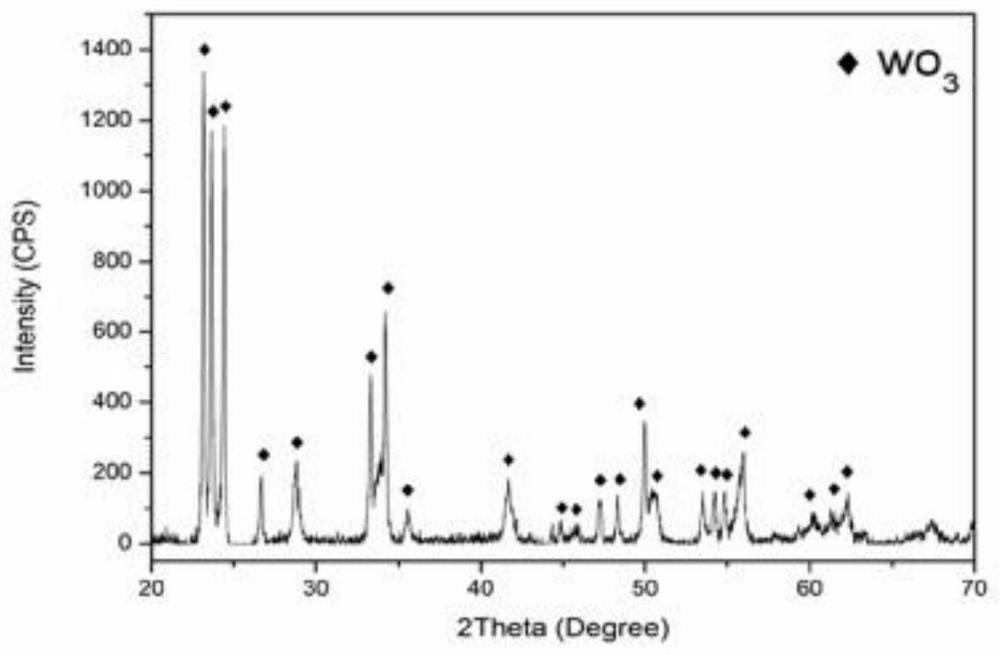

Cold isostatic pressing forming preparation method of tungsten oxide-based ceramic target material

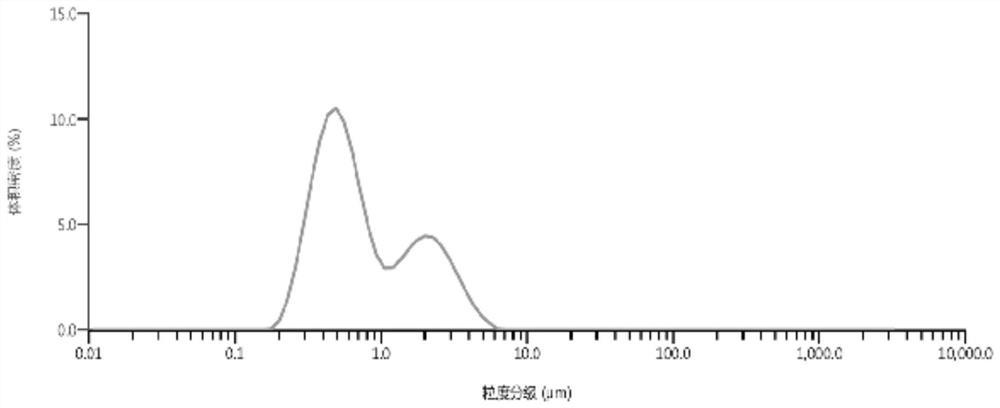

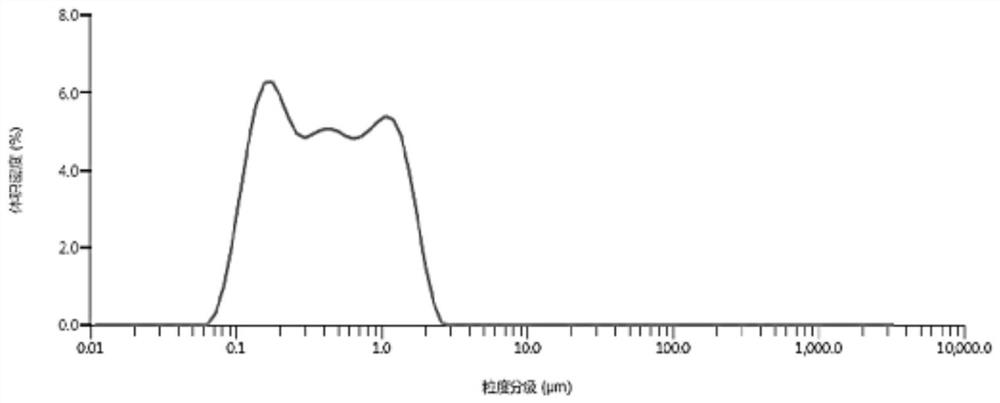

InactiveCN112479707AWide particle size distributionHigh bulk densityVacuum evaporation coatingSputtering coatingHigh densityMetallurgy

The invention relates to a cold isostatic pressing forming preparation method of a tungsten oxide-based ceramic target material, which comprises the following steps of raw material preparation: takingprimary mixed powder containing high-purity tungsten oxide and doping source powder, enabling the doping source to be selected from at least three of Ti, Mo, V, Al, Li and Zr, enabling the purity ofthe mixed powder to be greater than 99.95%, enabling the average particle size to be 500nm to 1800nm, and enabling the D50 particle size to be 200-750nm, wherein the quantitative relation of M1, M2, M3, M4 and M5 conforms to the formula as described in the specification, conducting spray drying, powder filling and compaction, pressing, biscuit degumming and sintering, taking out the sintered blankafter heat preservation, and conducting or not conducting machining according to needs. The cold isostatic pressing forming preparation method can be used for preparing the tungsten oxide-based ceramic target material with good conductivity, higher purity, fine grain size and high density.

Owner:北京航大微纳科技有限公司

High temperature resistant and low compression permanent deformation ethylene propylene diene monomer and preparation method thereof

InactiveCN110498977AImprove high temperature compression set performance and high temperature aging resistanceFast vulcanizationDibenzoyl PeroxideOxide

The invention discloses a high temperature resistant and low compression permanent deformation ethylene propylene diene monomer, which comprises the following components by mass: 100 parts of raw ethylene propylene diene monomer, 20-30 parts of chloroprene rubber, 30-50 parts of graphene, 5-10 parts of zinc oxide, 0.6-3 parts of zinc stearate, 0.2-0.8 part of BaSO4, 50-80 parts of a reinforcing filler, 10-15 parts of benzoyl peroxide, 1-3 parts of a vulcanizing assistant, and 0.5-1 part of a composite additive. By means of mixing, remilling and vulcanization, the ethylene propylene diene monomer can be prepared, and has the advantages of good mechanical properties, high temperature resistance, low compression permanent deformation and easy edge tearing.

Owner:ANHUI LIXIN RUBBER TECH CO LTD

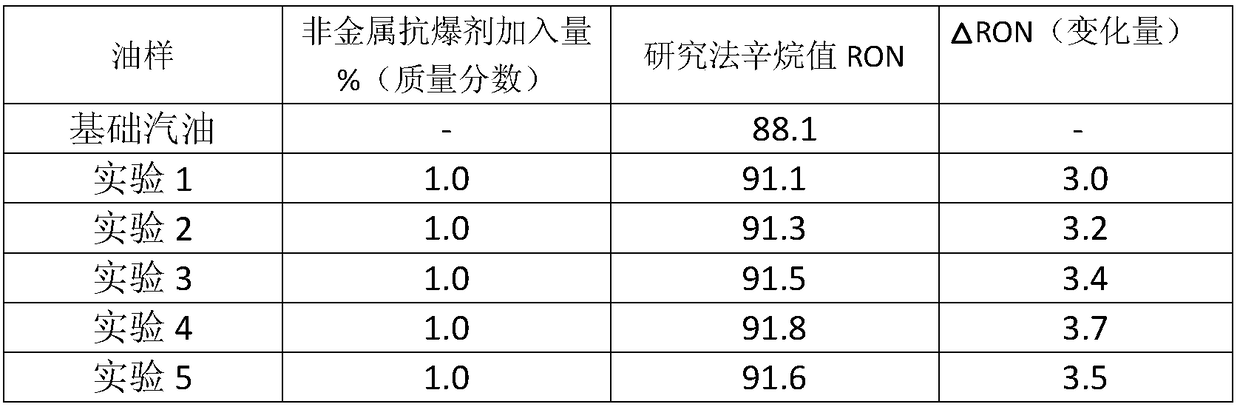

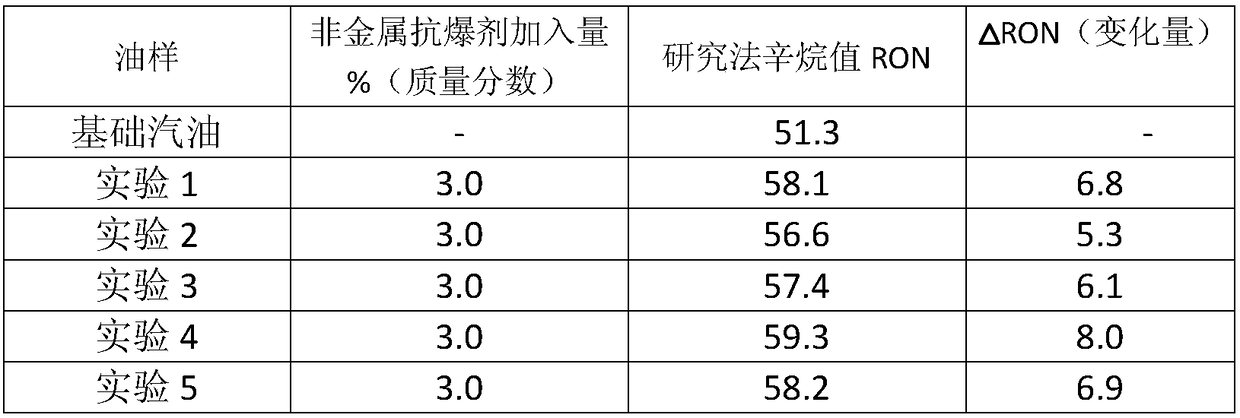

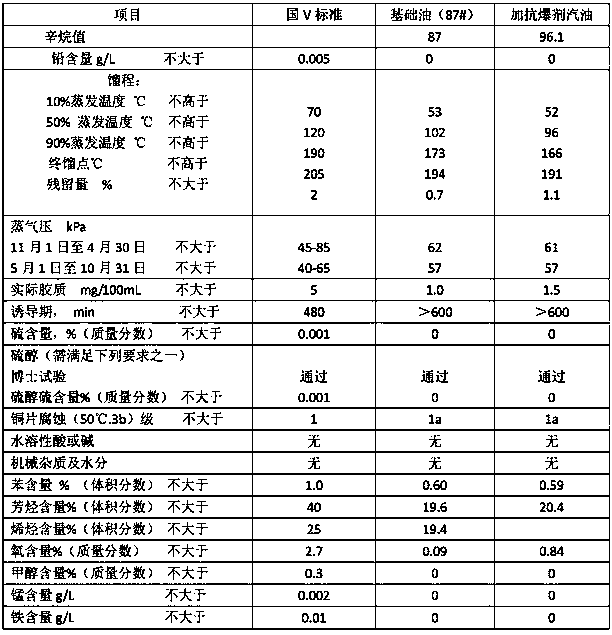

Non-metal antiknock agent for gasoline and preparation method of non-metal antiknock agent

InactiveCN108587705AImprove oxidation resistanceReduce gum contentLiquid carbonaceous fuelsFuel additivesExhaust gas emissionsSolvent

The invention discloses a non-metal antiknock agent for gasoline. The non-metal antiknock agent comprises the following active ingredients in parts by weight: 15-40 parts of an ester octane number modifier, 10-20 parts of an amine octane number modifier, 15-30 parts of an ether octane number modifier, 10-20 parts of an amide octane number modifier, 15-30 parts of an organic phenol octane number modifier, 3-8 parts of an alcohol octane number modifier, 3-8 parts of a cleaning dispersant, and 3-8 parts of a cosolvent. A preparation method of the non-metal antiknock agent for the gasoline comprises the following steps: (1) weighing the active ingredients in the corresponding parts by weight according to the foregoing requirements; (2) sequentially putting the ingredients into a reaction kettle with a stirring device, and performing full and uniform mixing under stirring; and (3) allowing the mixed solution to stand for one hour or more so as to obtain the non-metal antiknock agent. The non-metal antiknock agent disclosed by the invention effectively promotes improvement of an octane number of the gasoline, improves oxidation resistance of the gasoline, ensures indexes and quality of the gasoline, and reduces damage to the environment caused by exhaust gas emission; and the non-metal antiknock agent has predictable high economic value and social value.

Owner:张宝臣

Multi-wheel scutching integrated machine of degumming and rinshing

InactiveCN101270499BHigh degree of automationSimple and fast operationMechanical fibre separationEngineeringHigh pressure water

The invention relates to a multi-gear train integral machine of scotching, degumming and washing which includes a ramie feed unit, a bone-cutting skin-scraping unit and a bone-cracking ramie-extrudingunit; wherein, the bone-cutting skin-scraping unit mainly consists of a big round roll (1) and two rollers (2) and (3); the bone-cracking ramie-extruding unit mainly consists of a first small round roll (4) and a second small round roll(5). The big round roll is fixed on a frame through a bearing seat; the two rollers and the small round rolls are respectively mounted on the dump rails of each own through a sealing seat, arranged around the big round roll (1), respectively provided with a high pressure water scraper (6) which sprays water curtain along the tangent direction and opposite to the speed direction of the ramie, and the two ends of the shafts of the two rollers and the small round rolls are all provided with a pressurizing air cylinder (12). The machine finishes from ramie stalks to semi-fine dry ramie for one time and has the advantages of high automatization degree, safe use, good fiber separating effect, good ramie output, saving water, being beneficial to popularization, etc. The method can be used for processing fresh ramie so as to obtain semi-fine dry ramie.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com