Mica tape manufacturing method suitable for energy conservation, emission reduction and reduction of environmental pollution

A manufacturing method and technology of mica tape, applied in the direction of chemical instruments and methods, mica, lamination devices, etc., can solve the problems of increasing the production cost of mica tape, high production cost of mica tape, and large consumption of organic solvents, etc., to reduce baking temperature, reduce production cost, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

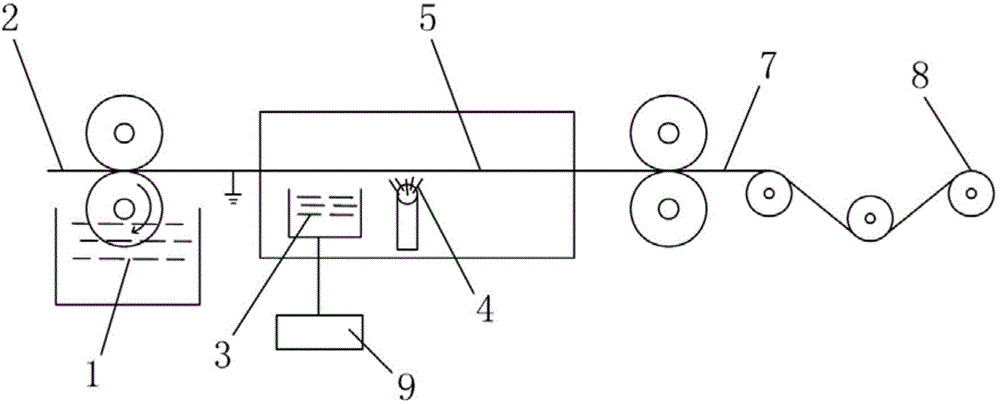

[0022] Example 1: Single-sided reinforced mica tape

[0023] Nanomaterials whose surface has been activated are added to mica powder, the amount of nanomaterials is 15% of the mass of mica powder; the nanomaterials and mica powder are uniformly dispersed by high-speed stirring to obtain mica raw material 3.

[0024] The nanomaterial is a mixture of 32wt% aluminum oxide and 68wt% aluminum nitride.

[0025] In order to reduce the amount of organic solvent used in the production of mica tape, when preparing the first adhesive 1, the solid content of the adhesive was controlled at 77wt%, added to the glue tank, glued with a roller and applied to the lower end surface of the reinforcing material 2 , according to the requirements of the mica tape glue content, adjust the amount of glue applied to the reinforcing material by the roller, turn on the power supply of the electrostatic generator 9, and make the mica raw material 3 and the reinforcing material be charged with opposite cha...

Embodiment 2

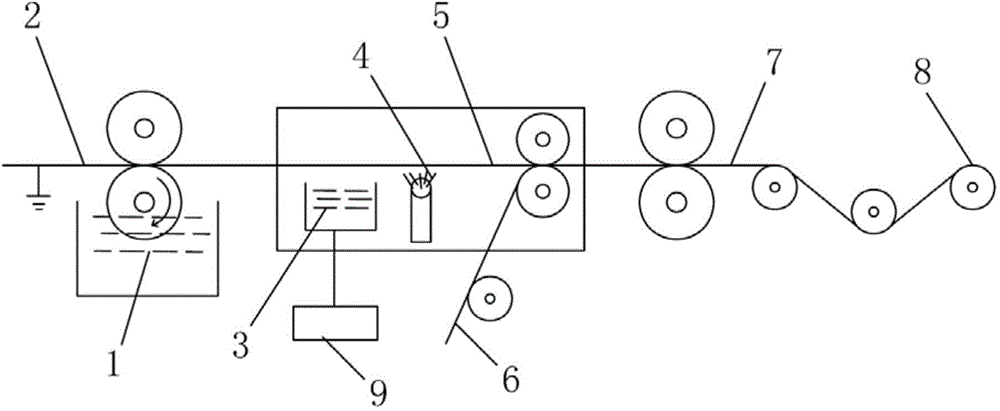

[0029] Example 2: Double-sided reinforced mica tape

[0030] Nanomaterials whose surface has been activated are added to mica powder, the amount of nanomaterials is 15% of the mass of mica powder; the nanomaterials and mica powder are uniformly dispersed by high-speed stirring, and mica raw material 3 is obtained.

[0031] The nanomaterial is a mixture of 40wt% aluminum oxide and 60wt% aluminum nitride.

[0032] In order to reduce the amount of organic solvent used in mica tape production, the solid content of the adhesive is controlled at 78% when preparing the adhesive, added to the glue tank, glued with a roller and applied to the lower end of the reinforcing material 2, according to the mica The content of the adhesive tape requires adjusting the amount of glue coated on the reinforcing material by the roller, and turning on the power of the electrostatic generator 9, so that the mica raw material 3 is absorbed and pasted on the reinforcing material 2; the mica raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com