Ionic liquid-chemical combined degumming method

An ionic liquid and chemical degumming technology, applied in the field of textile processing, can solve the problems of unsatisfactory degumming effect, long time-consuming degumming process, poor pretreatment effect, etc., and achieve low production cost, easy recycling and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

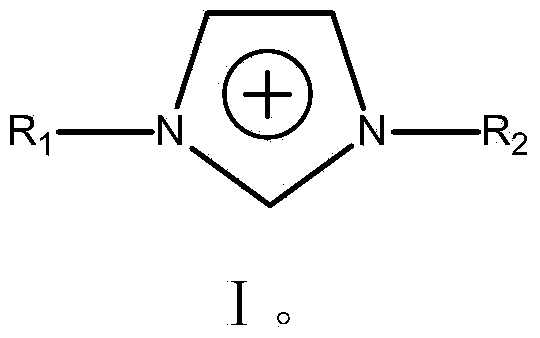

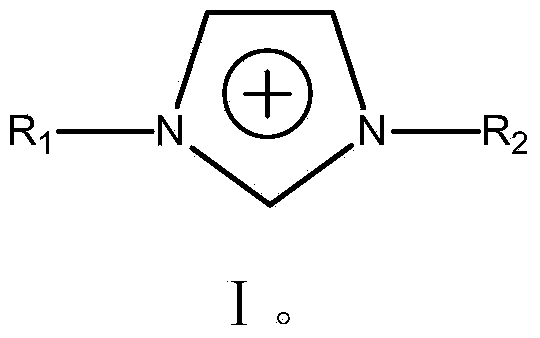

[0027] Pretreatment: First, add the raw apocynum hemp into deionized water according to the bath ratio of 1:20, boil it in water at 70°C for 3 hours, wash it, and then add [Bmim][ OAc] in an aqueous solution of ionic liquid, mechanically stirred, reacted at 90° C. for 4 hours, cooled to room temperature, separated by filtration, and the obtained hemp fiber was washed and dried. The original gum content of Apocynum hemp is 53.93%, and the residual gum rate after pretreatment is 27.06%.

[0028] Chemical degumming: add hemp fiber obtained after pretreatment to lye (NaOH 8g / L, NaOH 5 P 3 o 10 2.5%, bath ratio 1:20, temperature 90°C) for the first boiling and stirring for 1.5h, washed with water, and then for the second boiling (NaOH 12g / L, NaOH 12g / L, NaOH 5 P 3 o 10 2%, bath ratio 1:20, temperature 90°C) and stirred for 2.5h, then washed, dried, knocked and kneaded to obtain degummed Apocynum, and the residual glue rate was 3.95%.

[0029] The filtrate obtained during the ...

Embodiment 2

[0032] Pretreatment: First, add the raw apocynum hemp into deionized water according to the bath ratio of 1:20, boil it in water at 70°C for 3 hours, wash it, and then add [Bmim][ OAc] in the ionic liquid aqueous solution, mechanically stirred, reacted at 50° C. for 3 hours, cooled to room temperature, separated by filtration, and the obtained hemp fiber was washed and dried. The original gum content of Apocynum hemp is 53.93%, and the residual gum rate after pretreatment is 35.55%.

[0033] Chemical degumming: the gained hemp fiber is added to lye (NaOH 8g / L, NaOH 5 P 3 o 10 2.5%, bath ratio 1:20, temperature 90°C) for the first boiling and stirring for 1.5h, washed with water, and then for the second boiling (NaOH 12g / L, NaOH 12g / L, NaOH 5 P 3 o 10 2%, bath ratio 1:20, temperature 90°C) and stirred for 2.5h, then washed, dried, knocked and kneaded to obtain degummed apocynum, and the residual glue rate was 4.05%.

[0034] Add 5 times the volume of hot water at 80°C to ...

Embodiment 3

[0037] Pretreatment: First, add the raw apocynum hemp into deionized water according to the bath ratio of 1:20, boil it in water at 70°C for 3 hours, wash it, and then add [Bmim][ OAc] in the ionic liquid aqueous solution, carry out mechanical stirring, at 70 ℃ temperature, after reacting for 2h, drop to room temperature, filter and separate, the gained hemp fiber is washed and dried, the original gum content rate of Apocynum hemp is 53.93%, after pre-treatment After treatment, the residual glue rate was measured to be 34.96%.

[0038]Chemical degumming: the gained hemp fiber is added to lye (NaOH 8g / L, NaOH 5 P 3 o 10 2.5%, bath ratio 1:20, temperature 90°C) for the first boiling and stirring for 1.5h, washed with water, and then for the second boiling (NaOH 12g / L, NaOH 12g / L, NaOH 5 P 3 o 10 2%, bath ratio 1:20, temperature 90°C) and stirred for 2.5h, then washed, dried, knocked and kneaded to obtain degummed apocynum, and the residual glue rate was 3.94%.

[0039] Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com