Rubber composition used for production of automobile engine coolant hose inner and outer rubber layers and production method thereof

A rubber composition and automobile engine technology, which is applied in the field of rubber composition for manufacturing the inner and outer rubber layers of automobile engine coolant hoses, can solve the problems of high cost of engine coolant hoses, achieve improved oxidation resistance and degradation performance, and good long-term durability Coolant performance and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

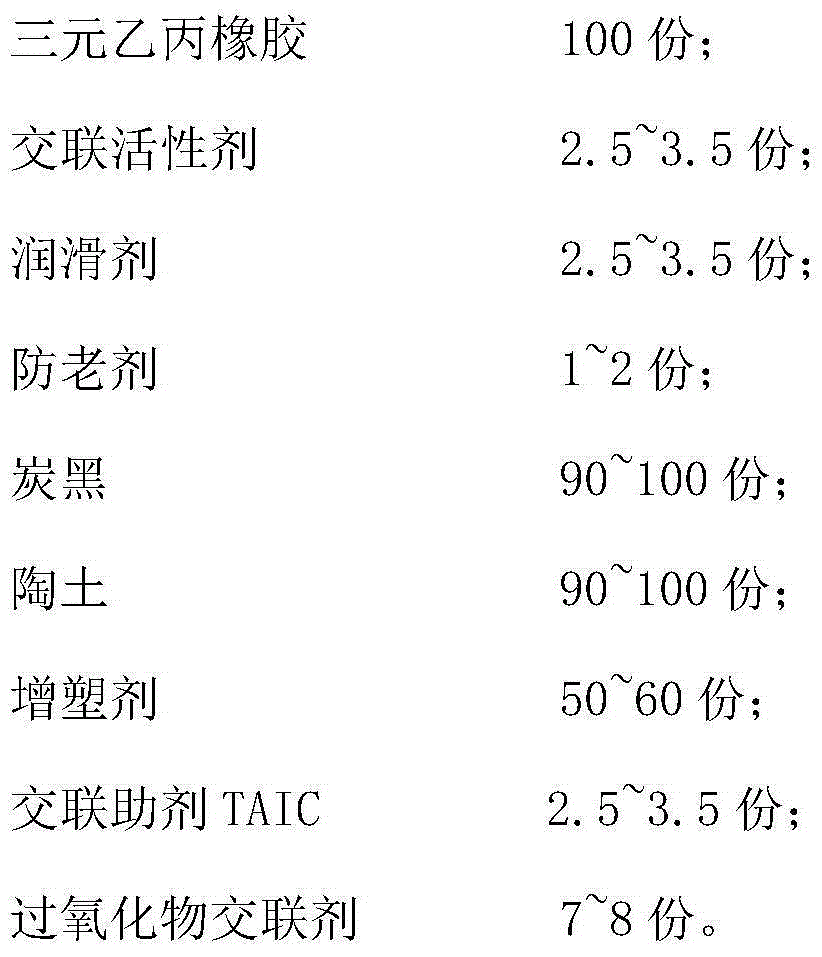

[0022] The rubber composition used to manufacture the inner and outer rubber layers of the automobile engine coolant hose, the raw material components and their parts by mass are as follows:

[0023]

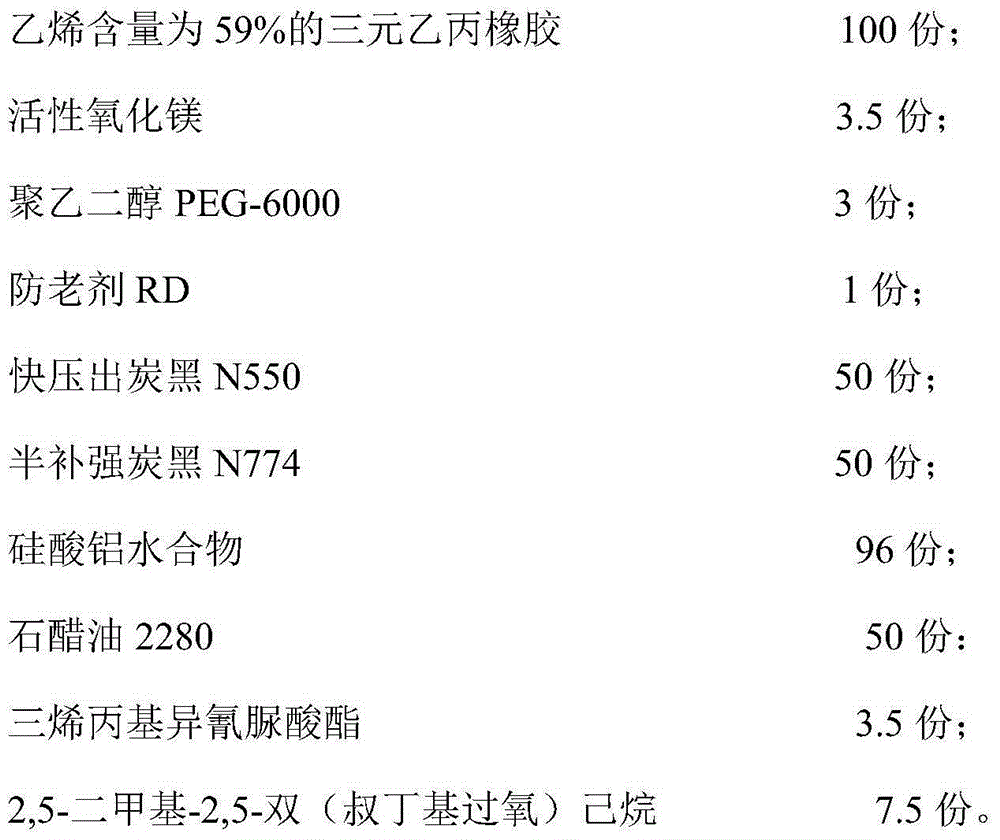

[0024] Producing familiar rubber composition, carry out according to the following steps:

[0025] EPDM rubber with an ethylene content of 59%, activated magnesia, polyethylene glycol PEG-6000, and anti-aging agent RD were mixed under pressure, and then petroleum vinegar 2280, aluminum silicate hydrate, and quick-pressed Add carbon black N550 and semi-reinforcing carbon black N774 for mixing, and finally add triallyl isocyanurate and 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane for Mixing, when the temperature reaches 120°C-135°C, discharge the mixed rubber material to the open mill and mix for 2-5 minutes, and then press it on the tablet machine to form a strip-shaped rubber combination suitable for processing thing.

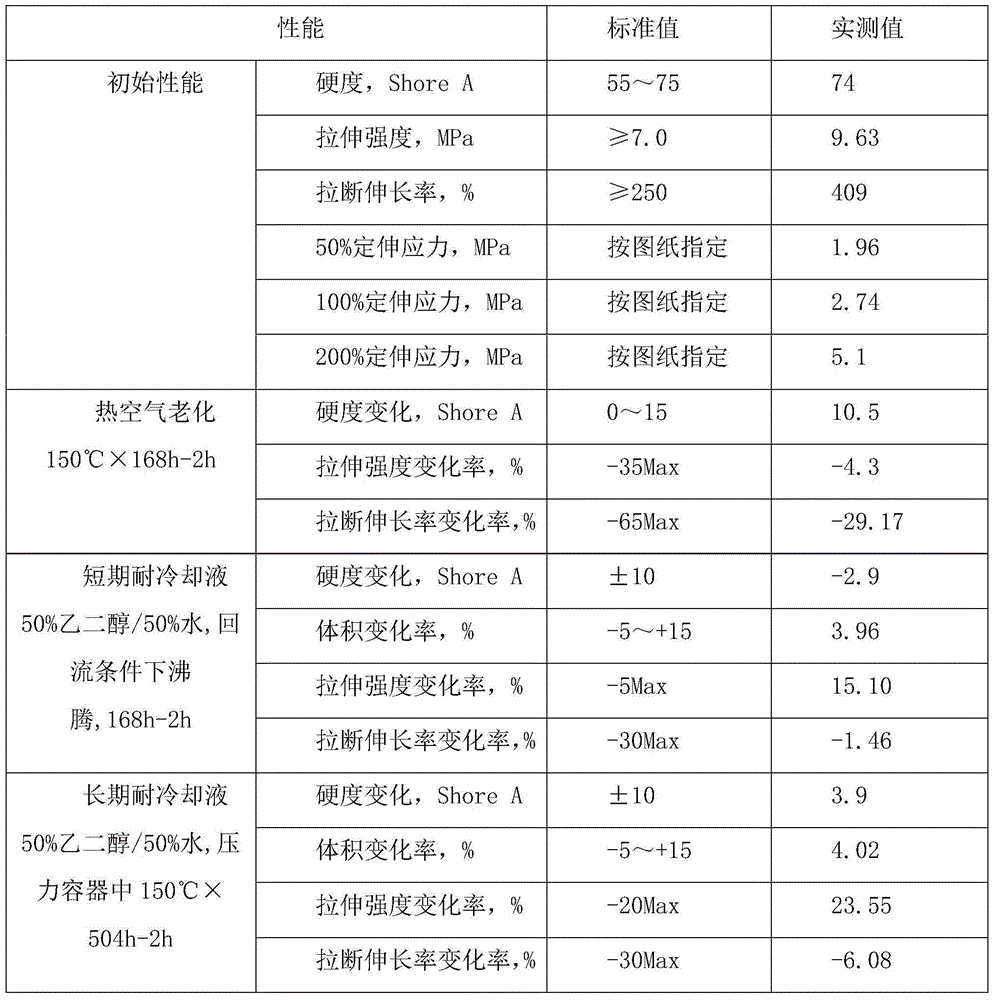

[0026] The rubber composition vulcanizate obtained abo...

Embodiment 2

[0029] The rubber composition used to manufacture the inner and outer rubber layers of the automobile engine coolant hose, the raw material components and their parts by mass are as follows:

[0030]

[0031]

[0032] Producing familiar rubber composition, carry out according to the following steps:

[0033] EPDM rubber with an ethylene content of 65%, activated magnesium oxide, polyethylene glycol PEG-6000, and anti-aging agent NBC were mixed under pressure, and then petroleum vinegar 2280, aluminum silicate hydrate, and quick-pressed Add carbon black N550 for mixing, and finally add triallyl isocyanurate and 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane for mixing, when the temperature reaches 120 When the temperature is ℃~135℃, the mixed rubber material is discharged to the open mill and mixed for 2~5 minutes, and then pressed on the tablet machine to form the rubber composition suitable for processing.

[0034] The rubber composition vulcanizate obtained above is tak...

Embodiment 3

[0038] The rubber composition used to manufacture the inner and outer rubber layers of the automobile engine coolant hose, the raw material components and their parts by mass are as follows:

[0039]

[0040] Producing familiar rubber composition, carry out according to the following steps:

[0041] EPDM rubber with an ethylene content of 71%, activated magnesia, polyethylene glycol PEG-6000, anti-aging agent RD, and anti-aging agent NBC were mixed under pressure, and then petroleum vinegar 2280, aluminum silicate hydrate , semi-reinforcing carbon black N774 was added for mixing, and finally triallyl isocyanurate and 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane were added for mixing, When the temperature reaches 120° C. to 135° C., discharge the mixed rubber material to the open mill for back-gluing and kneading for 2 to 5 minutes, and then press it on a tablet machine to form the rubber composition suitable for processing in the shape of a rubber strip.

[0042] The rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com