Temperature-deformation-resistant conveying belt and preparation method thereof

A conveyor belt and temperature-resistant technology, which is applied in the field of temperature-resistant deformed conveyor belt and its preparation, can solve the problems of affecting the wear resistance of the conveyor belt, shortening the service life, and reducing the structural stability of the conveyor belt, so as to improve the resistance to oxidation and degradation Performance, anti-aging shrinkage, good anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A temperature-resistant conveyor belt, including the following raw materials: 60kg of acrylic rubber, 200kg of silicone rubber, 50kg of carbon black, 20kg of skeleton fabric, 15kg of epoxy resin, 20kg of dicumyl peroxide, 10kg of carbon fiber, 20kg of calcium carbonate, Titanium dioxide 5kg, m-phenylenediamine 16kg, iron sulfide 5kg, stearic acid 10kg, antioxidant 5kg, clay 15kg.

[0053] Among them, the skeleton fabric is polyester canvas, and the anti-aging agent is paraffin.

[0054] A method for preparing a temperature-resistant deformed conveyor belt, comprising the following steps: after stirring epoxy resin and m-phenylenediamine at 250°C, uniformly apply it at 180°C, and dry it for 2 hours Skeleton woven polyester canvas on both sides to form a bonding layer; acrylic rubber, silicone rubber, dicumyl peroxide, carbon fiber, calcium carbonate, titanium dioxide iron sulfide, stearic acid, anti-aging agent and clay are stirred and mixed After uniformity, it was mel...

Embodiment 2

[0056] The difference with Example 1: 80kg of acrylate rubber, 180kg of silicone rubber, 40kg of carbon black, 30kg of skeleton fabric, 10kg of epoxy resin, 18kg of dicumyl peroxide, 12kg of carbon fiber, 15kg of calcium carbonate, 8kg of titanium dioxide, 10kg of phenylenediamine, 8kg of iron sulfide, 12kg of stearic acid, 6kg of antioxidant, and 12kg of clay.

Embodiment 3

[0058] The difference with Example 1: 100kg of acrylate rubber, 120kg of silicone rubber, 50kg of carbon black, 20kg of skeleton fabric, 15kg of epoxy resin, 15kg of dicumyl peroxide, 15kg of carbon fiber, 5kg of calcium carbonate, 10kg of titanium dioxide, 5kg of phenylenediamine, 10kg of iron sulfide, 5kg of stearic acid, 8kg of antioxidant, and 6kg of clay.

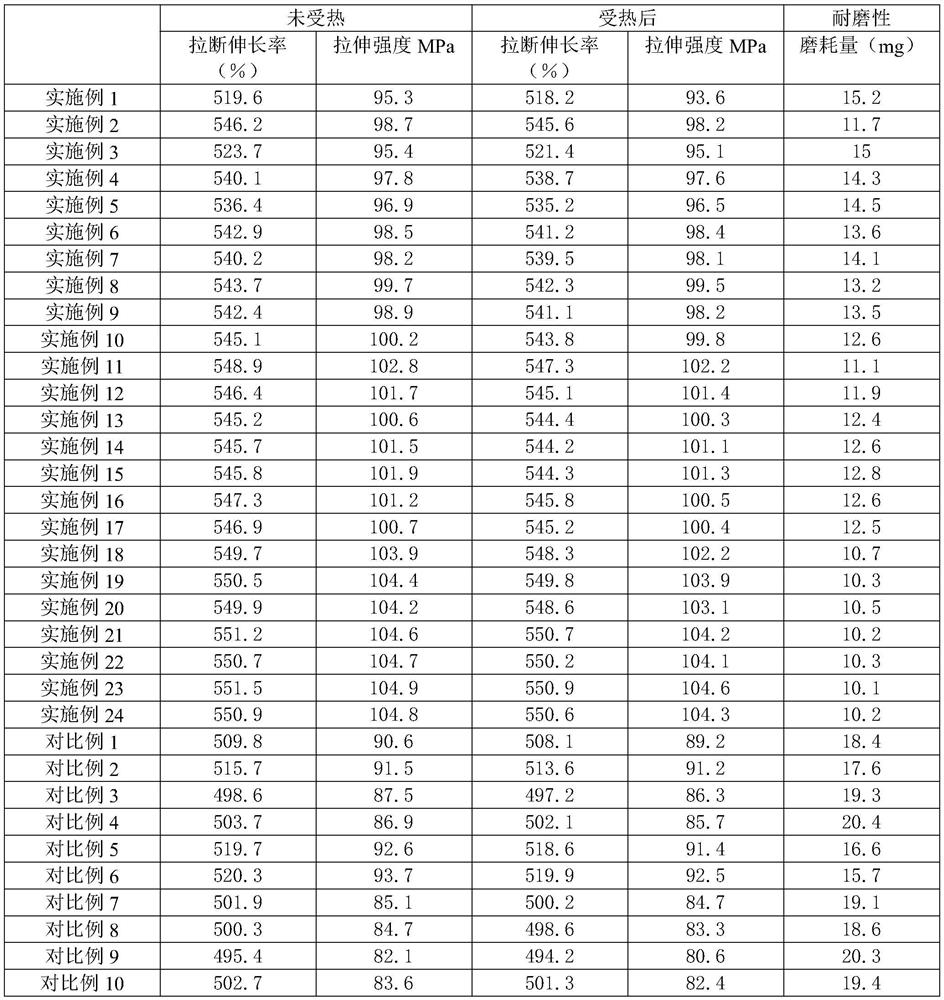

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com