Thermoplastic vulcanized rubber material for dish washer sealing strip and preparation method

A technology of thermoplastic vulcanization and rubber materials, which is applied in the field of thermoplastic vulcanized rubber materials and preparations for dishwasher sealing strips. It can solve the problems of unstable vulcanization and foaming processes, high cost of sealing strips, and complicated processing processes, and improve the anti-oxidative degradation performance. , Good dimensional stability and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Adopt the above-mentioned a kind of preparation method that is used for the thermoplastic vulcanized rubber material of dishwasher sealing strip, its specific steps are:

[0019] Step 1: Weighing: Accurately weigh each component according to the range of parts in claim 1;

[0020]Step 2: Mixing and banburying: Accurately weighed EPDM rubber, polypropylene, elastomer, part of filling oil, compatibilizer, anti-aging agent, lubricant, anti-aging agent according to the range of parts in claim 1 Put the fungicide and processing aid into the high-speed mixer. The speed of the high-speed mixer is set at 500-800r / min, and the mixing time is 10 minutes. After the mixing is completed, put the mixture into the internal mixer for internal mixing. The banburying temperature is set to 120-170°C, and the banburying time is set to 15-30min to obtain the premix;

[0021] Step 3: Mastication: After mixing the premix obtained in Step 2 with the vulcanizing agent accelerator, put it into ...

Embodiment 1

[0024] A kind of thermoplastic vulcanized rubber material used for dishwasher sealing strips weighs (weight) according to the following material parts among the present invention:

[0025] (Table 1:)

[0026] EPDM

100 copies

Homopolypropylene

30 copies

20 copies

50 copies

PP-g-MA

5 copies

2 copies

Accelerator NS

1 copy

Antiaging agent RD

0.3 parts

3 copies

DCOIT

0.2 parts

Processing aids

3 copies

[0027] The EPDM rubber, homopolypropylene, ethylene-octene copolymer, part of white oil, compatibilizer PE-g-MA, anti-aging agent RD, stearic acid after accurate weighing according to (Table 1:) , the antifungal agent DCOIT and processing aids are put into the high-speed mixer, the speed of the high-speed mixer is set at 500-800r / min, and the mixing time is 10min. After the mixing is completed, put the ...

Embodiment 2

[0031] (Table 2:)

[0032] EPDM

100 copies

Homopolypropylene

30 copies

20 copies

50 copies

PE-g-MA

5 copies

lead monoxide

6 servings

Accelerator TMTD

1.5 servings

Antiager AW

0.5 parts

PE wax

2 copies

2 copies

OBPA

0.2 parts

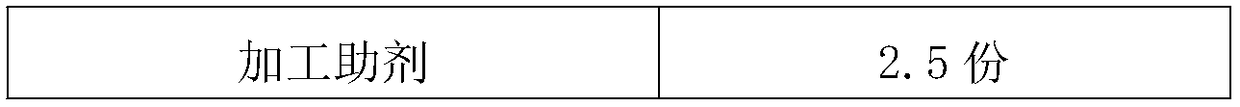

Processing aids

2.7 servings

[0033] The EPDM rubber, homopolypropylene, ethylene-octene copolymer, part of white oil, compatibilizer PE-g-MA, anti-aging agent AW, PE wax, Put oleic acid amide, antifungal agent (OBPA) and processing aid into the high-speed mixer. The speed of the high-speed mixer is set at 500-800r / min, and the mixing time is 10min. After the mixing is completed, put the mixture into the internal mixer The internal mixing is carried out, the internal mixing temperature of the internal mixer is set to 120-170°C, and the internal mixing time is set to 15-30min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com