Graphene composite heat-conducting gasket and preparation method thereof

A technology of graphene composite and thermal pads, which is applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve problems such as delamination, affecting mechanical stability, and high hardness of thermal pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In one embodiment, a kind of preparation method of graphene composite thermal pad is provided, comprising:

[0042] a) The graphene thermally conductive foam film is punched into sheets of consistent size, stacked layer by layer and put into a corresponding mold, and pressurized so that the film and the film are tightly bonded;

[0043] b) Apply the adhesive evenly around the pressured foam film so that it is completely covered into a block;

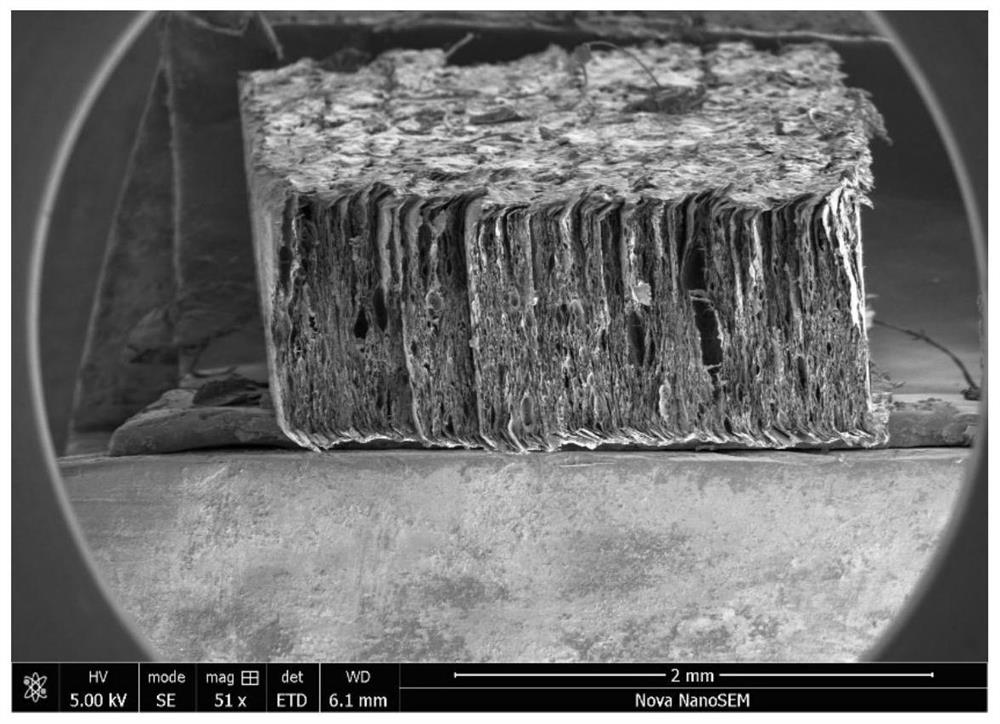

[0044] c) After the block is solidified and formed, it is cut into sheets along the stacking direction, such as image 3 shown;

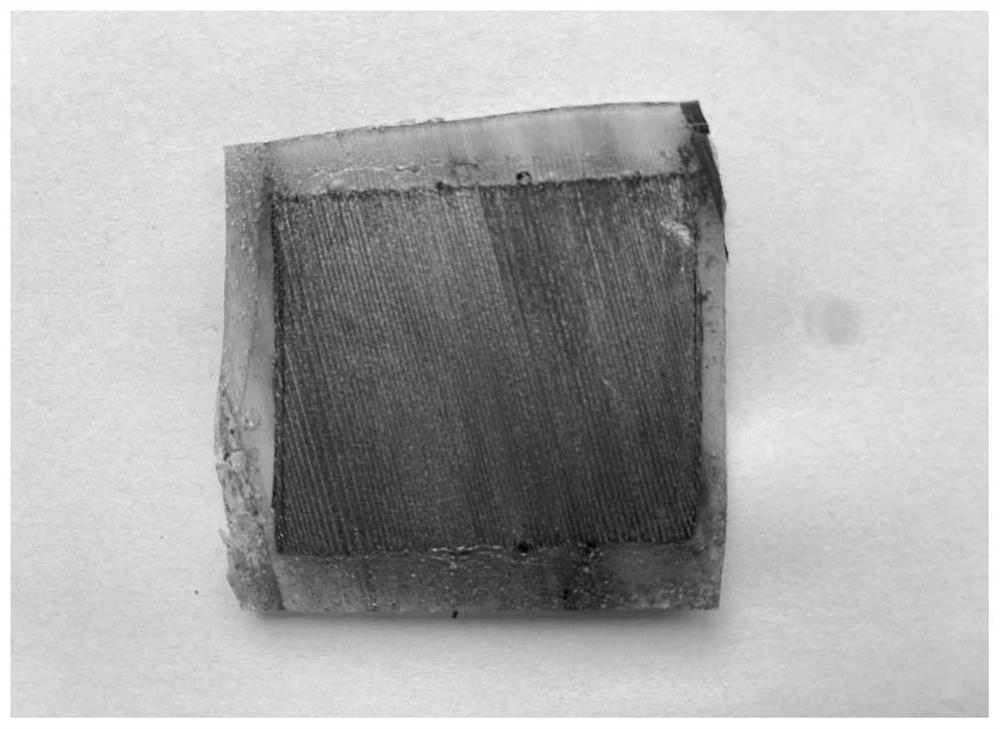

[0045] d) impregnating the cut sheet in the impregnating glue, taking it out, and hot pressing it;

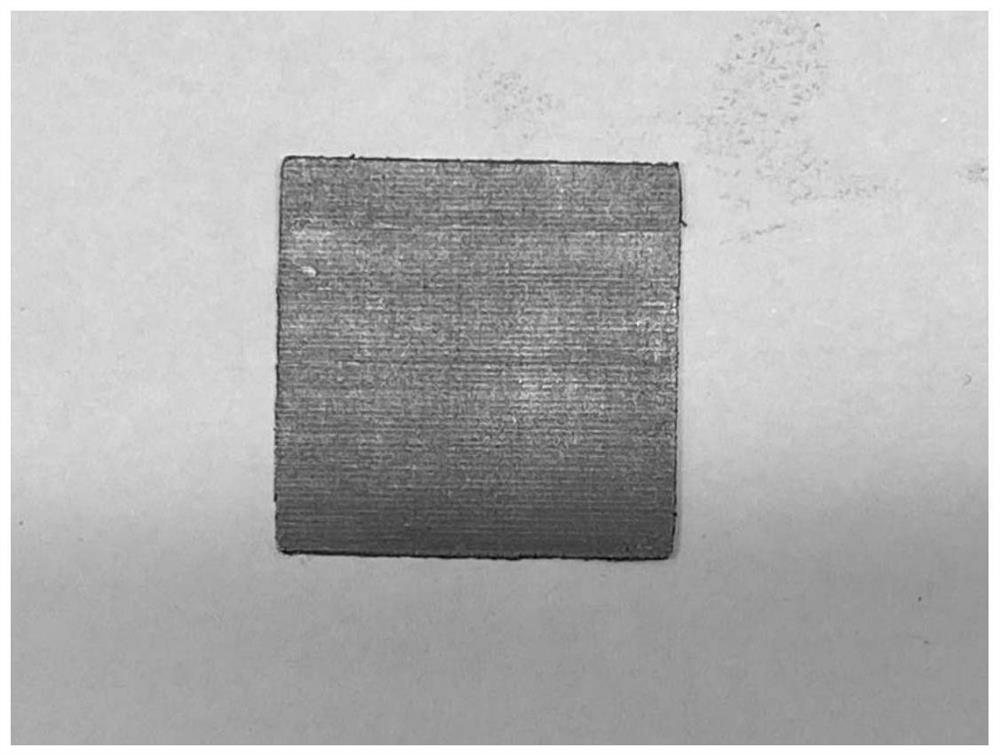

[0046] e) Trim the edge of the formed sheet, remove the bonding adhesive area on the edge, and obtain a thermal pad prepared by compounding the graphene foam film and the adhesive, such as figure 1 and 2 shown.

[0047] In step b), the adhesive is mainly distributed on the surface of the graphene fo...

Embodiment 1

[0057] In this embodiment, the graphene foam film accounts for 50wt.%, and the adhesive accounts for 50wt.%.

[0058] Graphene foam film thermal conductivity 50W / (m K);

[0059] Graphene foam film thickness 50μm, density 0.12g / cm 3 ;

[0060] The average pore size of the internal pores of the graphene foam film is 10 μm;

[0061] The bonding adhesive is heat-curable epoxy resin with a viscosity of 5000mPa·s and a curing temperature of 80°C;

[0062] The impregnation adhesive is liquid silica gel with a viscosity of 1000mPa·s;

[0063] Hot pressing process, pressure 0.1MPa, curing temperature 150°C;

[0064] After testing, the thermal conductivity of the sample is 22W / (m K), and the applied thermal resistance of samples with different thicknesses is shown in Table 1 below:

[0065] Table 1

[0066] Thickness (mm) Applied thermal resistance (K cm 2 / W)

Embodiment 2

[0068] In this embodiment, the graphene foam film accounts for 95wt.%, and the adhesive accounts for 5wt.%.

[0069] The thermal conductivity of graphene foam film is 400W / (m K);

[0070] Graphene foam film thickness 1000μm, density 0.88g / cm 3 ;

[0071] The average pore size of the internal pores of the graphene foam film is 100 μm;

[0072] The bonding adhesive is heat-curable epoxy resin with a viscosity of 300000mPa s and a curing temperature of 80°C;

[0073] The impregnation adhesive is liquid silica gel with a viscosity of 50mPa·s;

[0074] Hot pressing process, pressure 2.0MPa, curing temperature at room temperature;

[0075] After testing, the thermal conductivity of the sample is 305W / (m K), and the applied thermal resistance of samples with different thicknesses is shown in Table 2 below:

[0076] Table 2

[0077] Thickness (mm) Applied thermal resistance (K cm 2 / W)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com