Non-metal antiknock agent for gasoline and preparation method of non-metal antiknock agent

A gasoline antiknock agent and non-metallic technology, which is applied in the field of nonmetallic gasoline antiknock agent and its preparation, can solve the problems of affecting the normal operation of the engine, the octane number increase rate is not high, and the colloid content increases, reaching octane High value improvement rate, reduced gum content, and the effect of increasing gasoline octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Get ester octane number improver 15g, organic phenol octane number improver 20g amine octane number improver 15g, amides octane number improver 15g, alcohols octane number improver 5g, ethers octane number improver Value improver 20g, antioxidant 2.5g, detergent dispersant 2.5g, co-solvent 5g.

[0040] (3) Production process and preparation process: put the above-mentioned various octane number improvers into the reactor with stirring one by one according to the proportion, add each octane number improver and stir for 10 minutes, and then add the next one ; After all the addition is completed and stirred for 1 hour, the non-metallic gasoline antiknock agent is obtained after standing for reaction for more than 1 hour. Mix well and let stand for at least 1 hour.

Embodiment 2

[0042] Get esters octane number improver 10g, organic phenols octane number improver 20g, amines octane number improver 15g, amides octane number improver 15g, alcohols octane number improver 5g, ethers octane number improver 20g of alkane number improver, 2.5g of antioxidant, 2.5g of cleaning and dispersing agent, 5g of co-solvent.

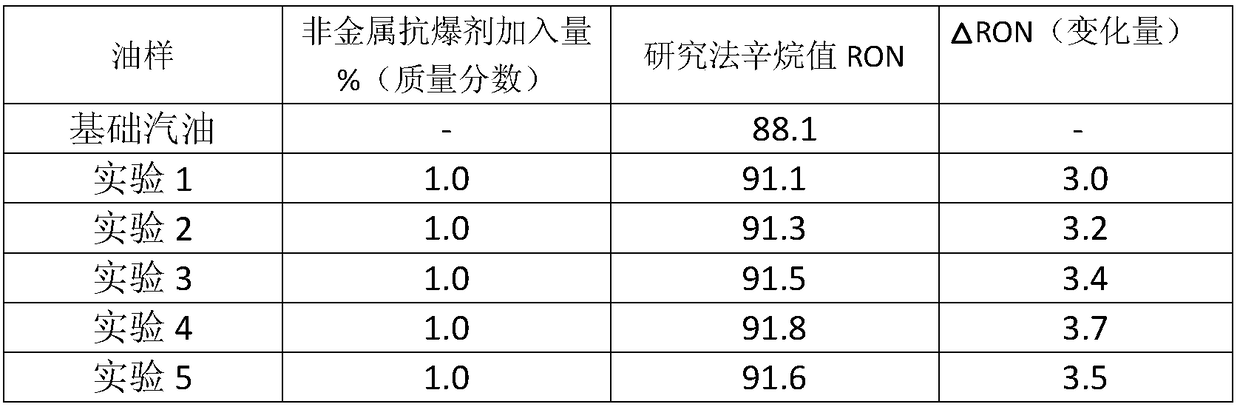

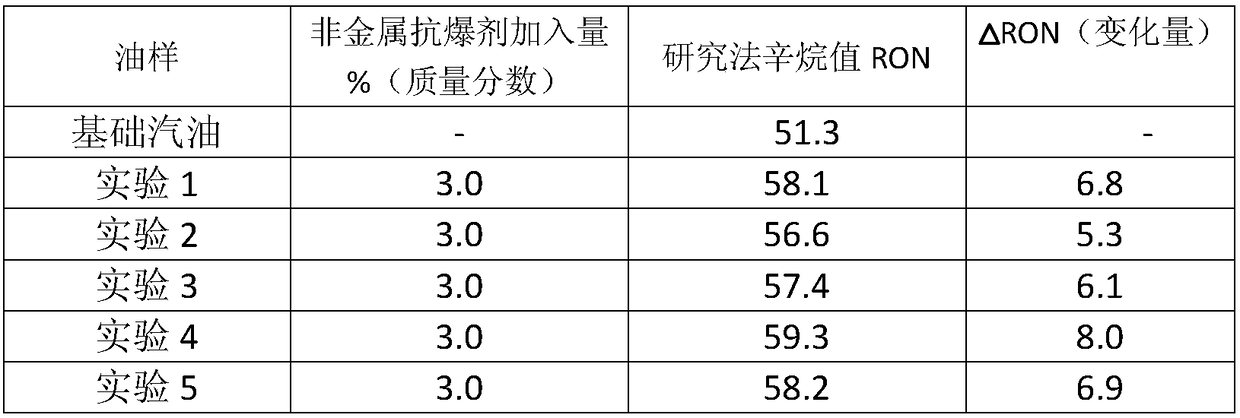

[0043] Production process and preparation process: Put the above-mentioned various octane number improvers into the reactor with stirring according to the proportion, and stir for 10 minutes after each octane number improver is added, and then add the next one; after all the additions are completed After stirring for 1 hour, the non-metallic gasoline antiknock agent is obtained by standing for reaction for more than 1 hour. (the present embodiment 2 is added in catalytically reformed gasoline, and the octane number improvement rate is shown in Table 1)

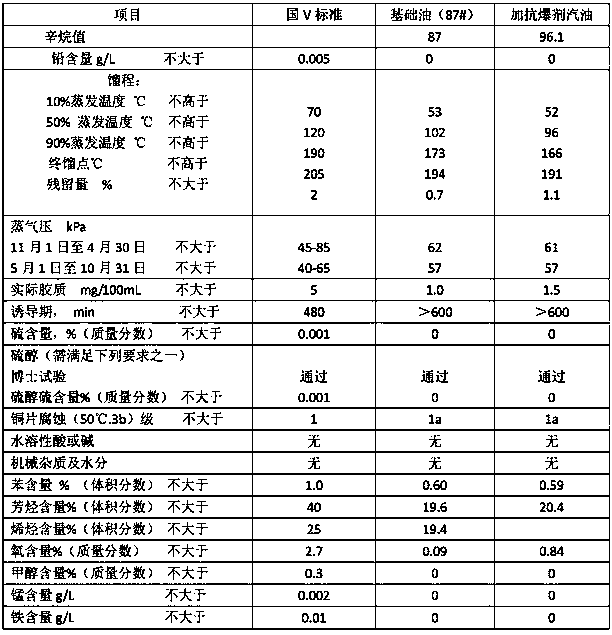

[0044] The non-metallic antiknock agent prepared in Example 2 was added to catalytically refor...

Embodiment 3

[0048] Get ester octane number improver 20g, organic phenols octane number improver 20g, amines octane number improver 15g, amide octane number improver 20g, alcohols octane number improver 5g, ethers octane number improver 10g of alkane number improver, 2.5g of antioxidant, 2.5g of cleaning and dispersing agent, 5g of co-solvent.

[0049] Production process and preparation process: Put the above-mentioned various octane number improvers into the reactor with stirring according to the proportion, and stir for 10 minutes after each octane number improver is added, and then add the next one; after all the additions are completed After stirring for 1 hour, the non-metallic gasoline antiknock agent is obtained by standing for reaction for more than 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com