Fiber bundle dividing and washing method and device

A water washing device and fiber bundle technology, applied in fiber treatment, bast fibers produced by chemical method, textiles and papermaking, etc., can solve the problems of high noise and labor intensity, difficult control of product quality, and fiber damage, etc., to improve production Efficiency, weakening binding force, enhancing vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

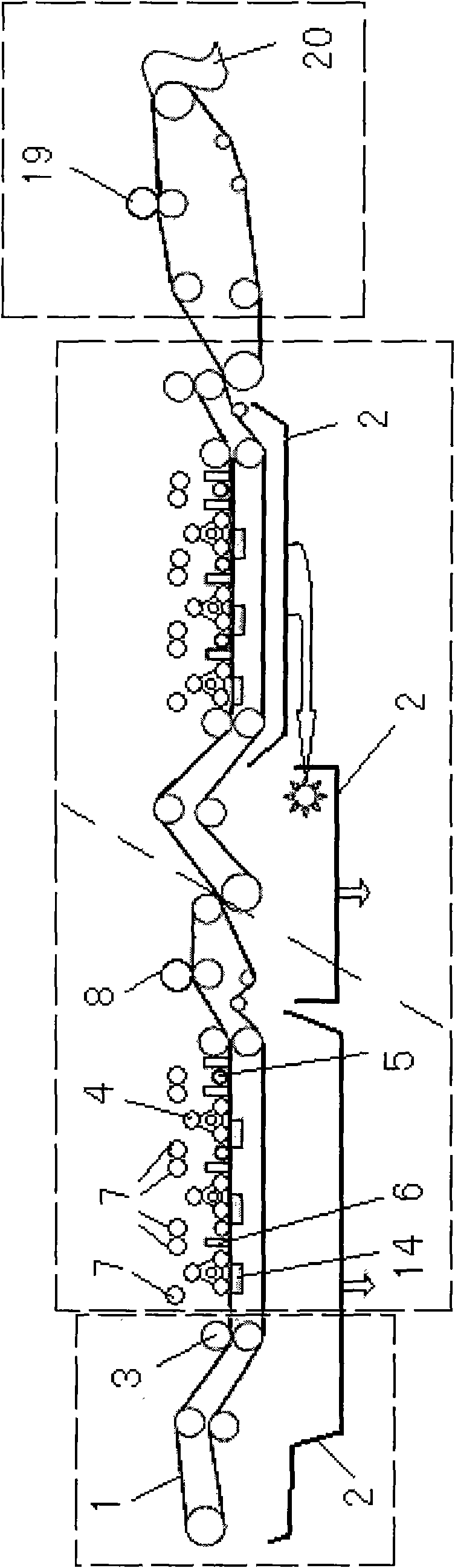

[0020] Such as figure 1 As shown, the present invention includes several component fiber washing units and a fiber output unit, and it is generally more appropriate to set up 2 to 4 groups of fiber dividing washing units. Each unit is driven by a rotary running track 1 arranged on the frame and driven by a motor, and each group of track 1 is stacked end to end to form an integral assembly line. Caterpillar 1 can adopt the mesh crawler of whole seamless interface, and the bottom of crawler belt 1 is provided with sump 2, and a water circulation treatment device can be set inside or outside sump 2, processing waste water can be recycled after treatment after flowing into sump 2.

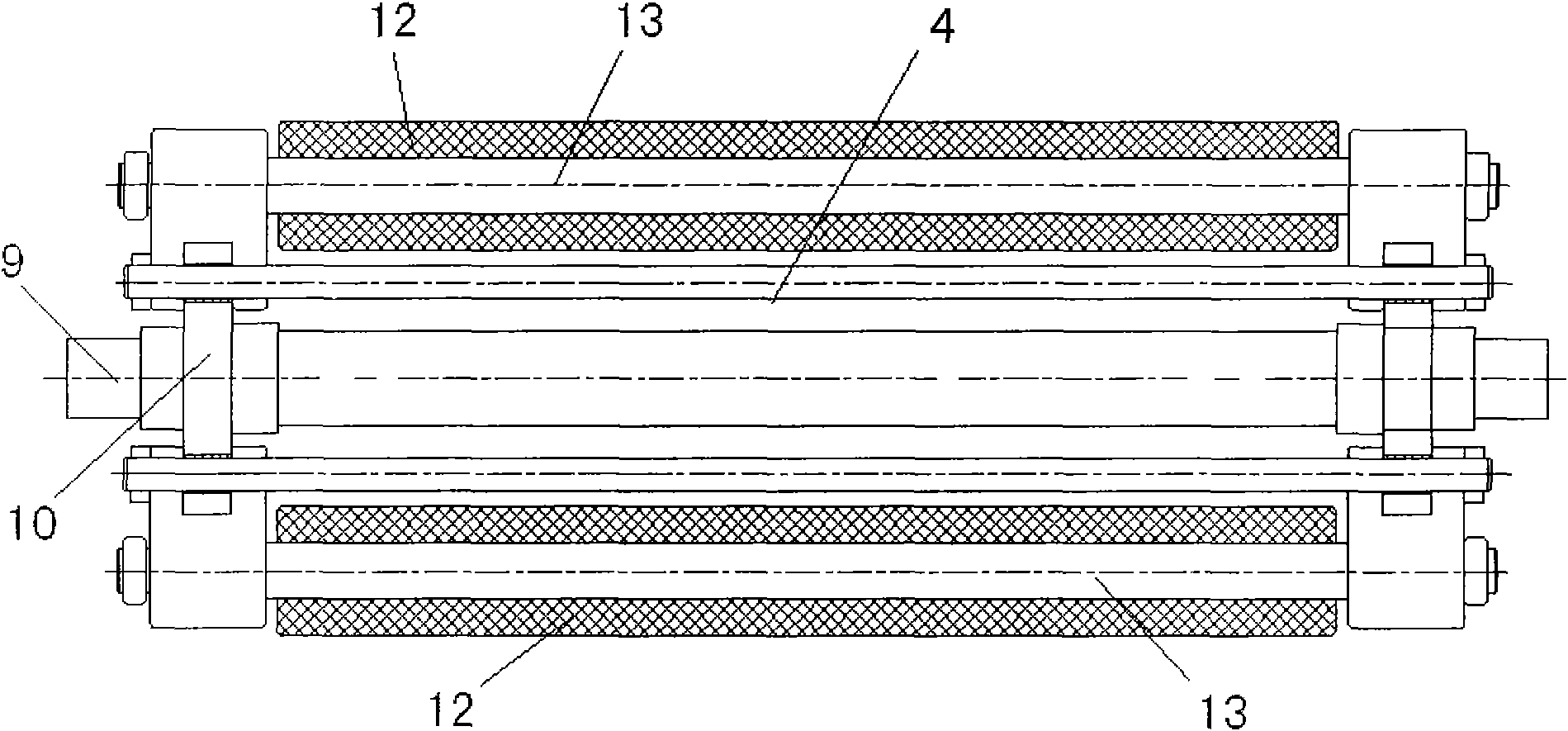

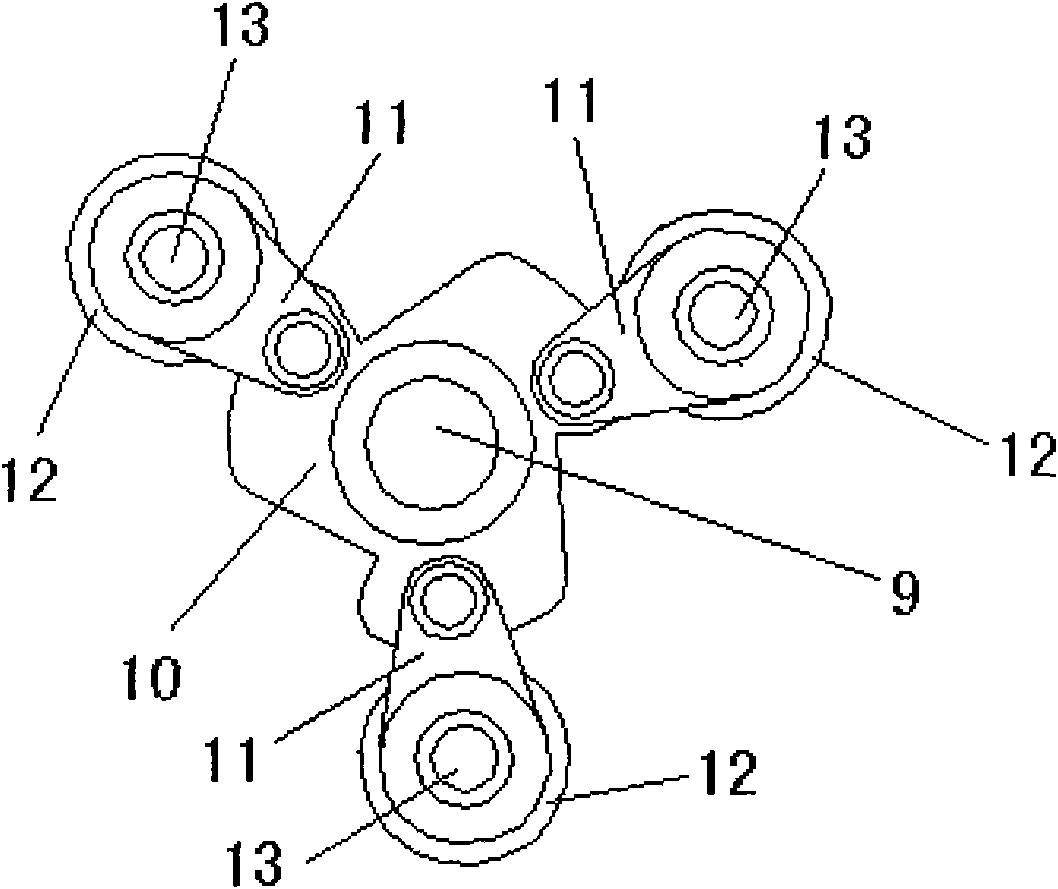

[0021] Each component fiber water washing unit includes a feed roller 3 arranged at the input end of the crawler belt 1, and several pressing rollers (not shown in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com