Method for conveying C<+>9 heavy aromatics to light aromatics

A technology for heavy aromatics and lightening, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as high reaction temperature and pressure, low space velocity, and industrial application restrictions, and achieve the reduction of colloids content, reducing the final boiling point, and the effect of high conversion rate of heavy aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

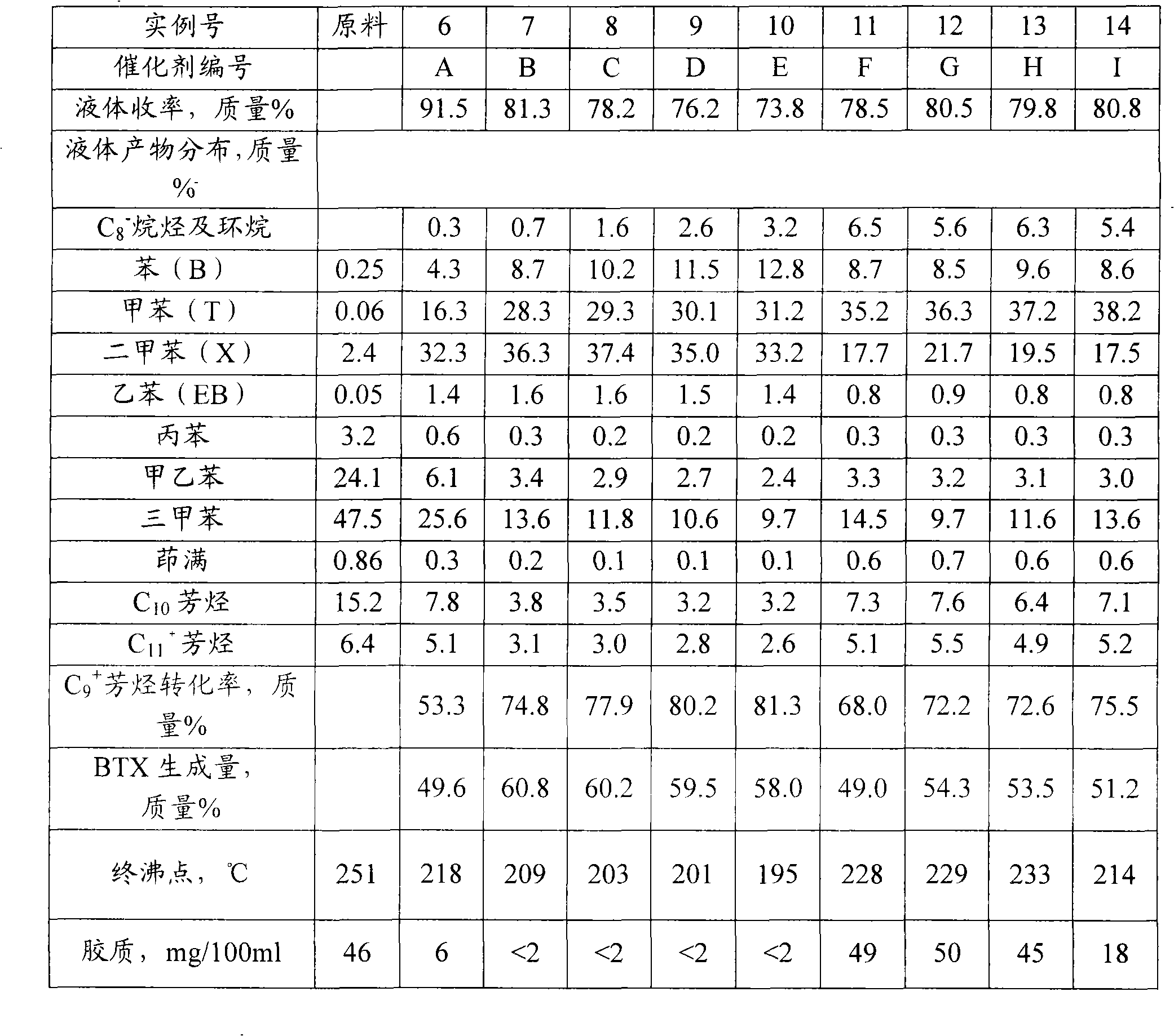

Examples

preparation example Construction

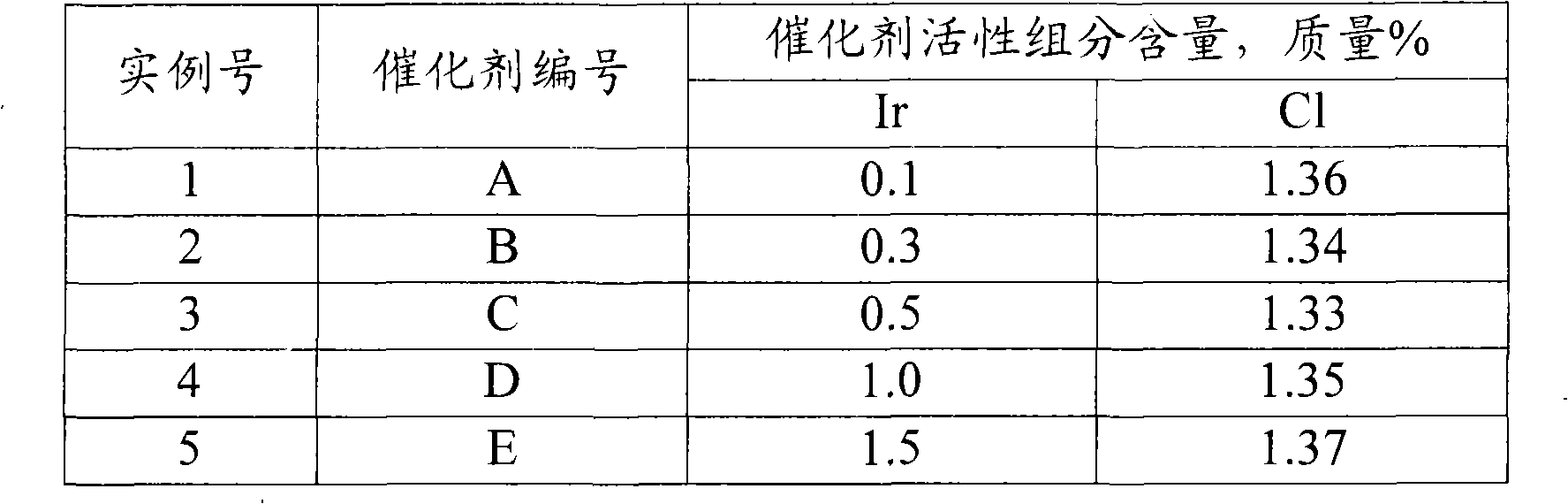

[0019] The preparation method of the catalyst of the invention comprises the steps of impregnating the molded high-temperature-resistant inorganic oxide with a solution containing an iridium compound, and performing water chlorine activation and reduction after drying.

[0020] The molding of the high temperature-resistant inorganic oxide can adopt conventional extrusion molding or drop ball molding.

[0021] The extrusion molding method is to knead the powdery high-temperature-resistant inorganic oxide or its precursor with an appropriate amount of water and a peptizer. The peptizer is generally an acid. Extrude the uniformly kneaded material, dry and roast to obtain the shaped carrier.

[0022] The method for forming the drop ball is: adding an appropriate amount of water to the powdery high-temperature-resistant inorganic oxide or its precursor, so that the liquid / solid mass ratio is 1.0-3.0. Stir to make it slurry, then add acid to acidify, add urea accounting for 20-40% ...

example 1

[0032] Preparation of the catalyst of the present invention.

[0033] (1) Preparation of γ-alumina carrier.

[0034] Take 100 grams of aluminum hydroxide powder (produced by German condea company, brand SB) and add 200 grams of deionized water, and stir to make it slurry. Add the nitric acid that volume ratio is 1: 1 by the amount of every 100 grams of SB powder 7.5 milliliters, add the concentration of 30 grams of urea and 10.0 grams simultaneously and be the hydrochloric acid solution of 36.5 mass %, stir 1 hour, add 30 grams of kerosene and stir 1 hour, The drop ball is formed in the oil ammonia column. The wet bulb was solidified in ammonia water with a concentration of 6.0% by mass for 1 hour, then filtered, washed 2 to 3 times with deionized water, dried at 60°C for 6 hours, and dried at 120°C for 10 hours, and then dried in dry air at a ratio of 700:1 The gas / solid volume ratio was calcined at 600° C. for 4 hours to obtain the gamma-alumina carrier.

[0035] (2) Prep...

example 2

[0038] Catalyst B was prepared according to the method of Example 1, except that the impregnating liquid used contained 0.3% by mass of Ir, and the active component content of catalyst B was shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com