C9 aromatic hydrocarbon lightening catalyst and lightening method thereof

A catalyst and aromatic technology, which is applied in the field of C9+ aromatics lightening catalyst and lightening, can solve the problems of low space velocity, high reaction temperature and pressure, industrial application limitations, etc., and achieves reduction of colloidal content and small loss of aromatic rings. , The effect of less side reactions of hydrogenation ring opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

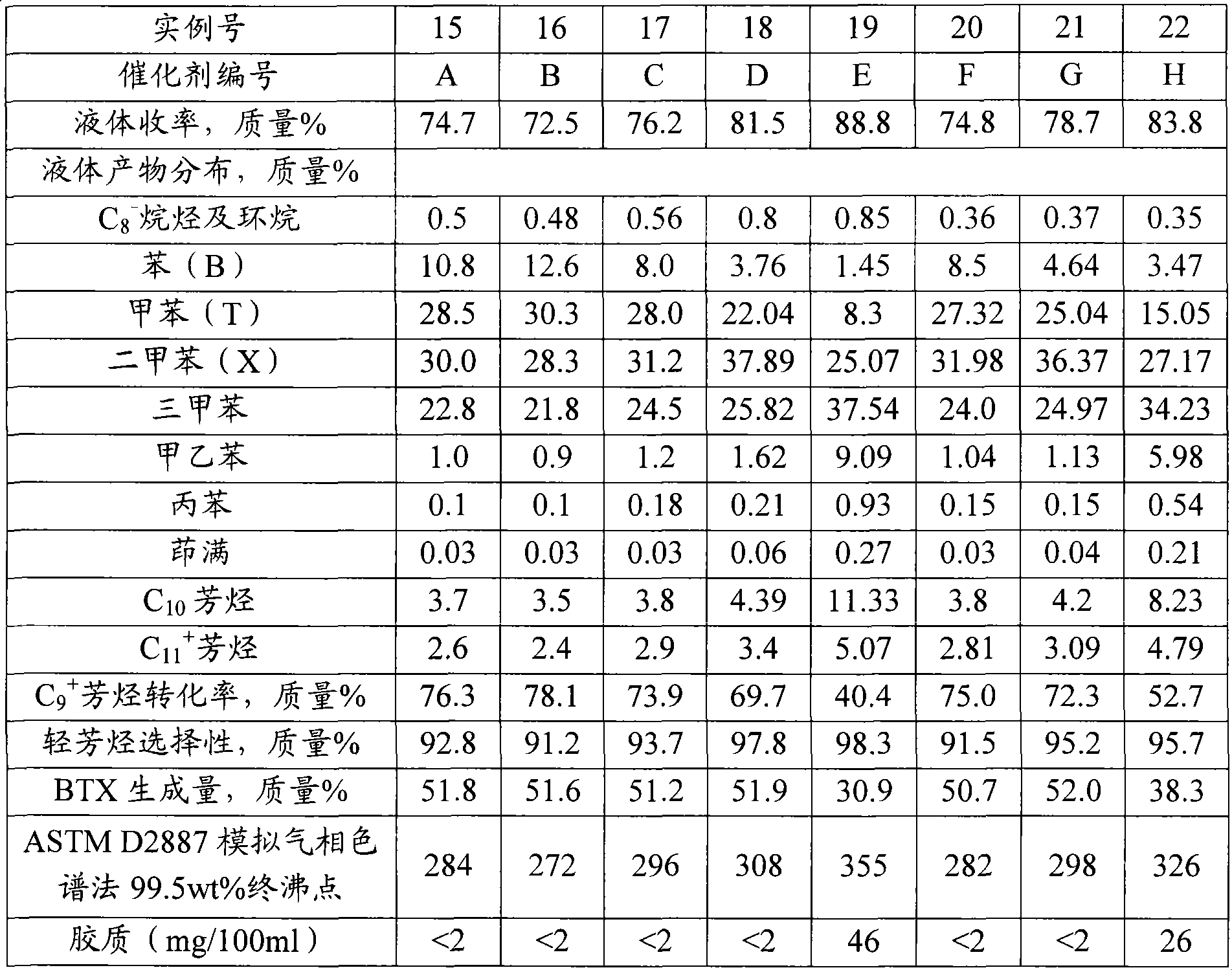

Examples

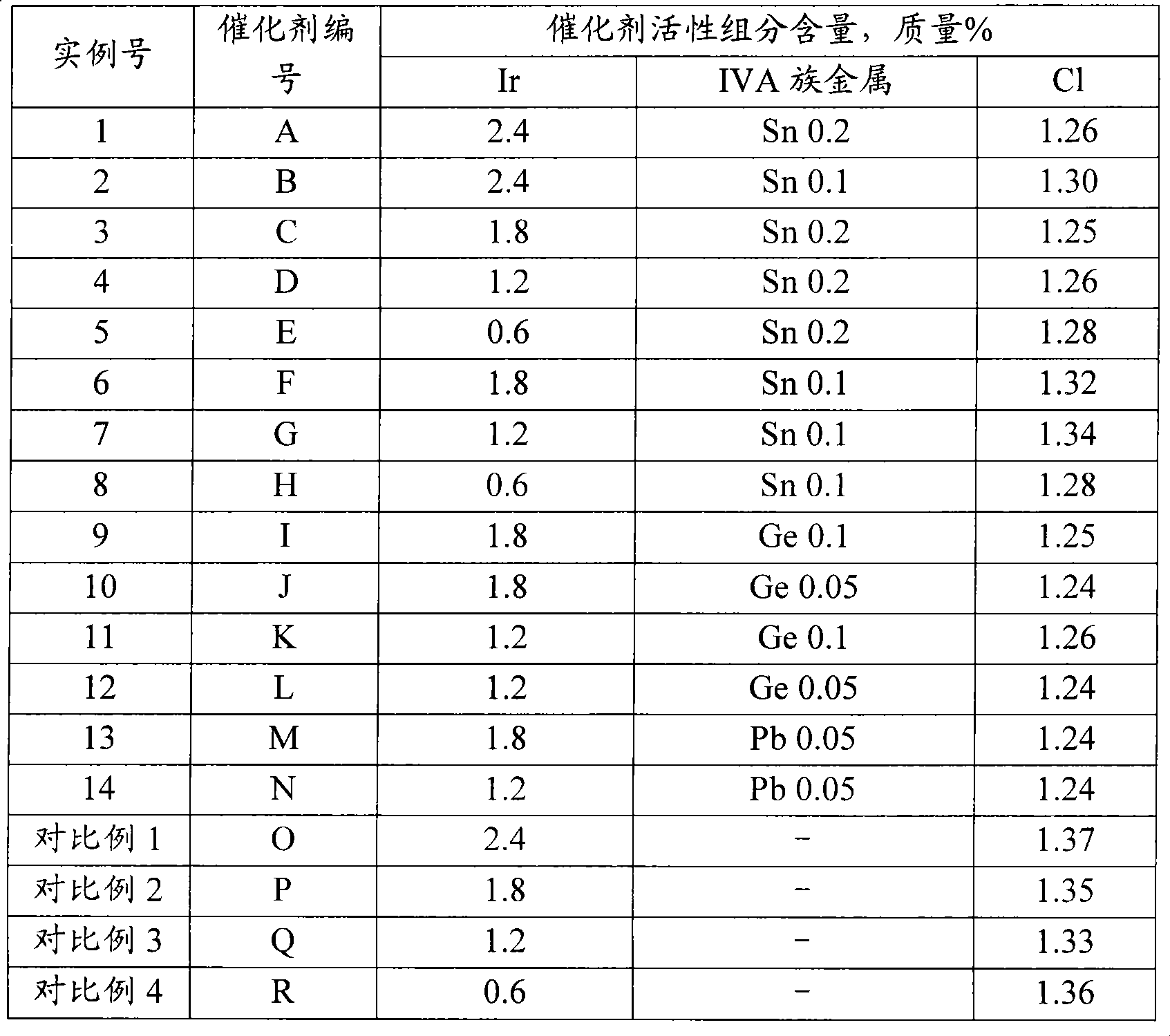

example 1

[0046] The Ir-Sn bimetallic catalyst described in the present invention is prepared.

[0047] (1) Preparation of γ-alumina carrier.

[0048] Take 135 grams of aluminum hydroxide powder (manufactured by Condea Company, brand SB) and add 200 grams of deionized water, and stir to make it slurry. According to the amount of 7.5 milliliters per 100 grams of SB powder, add nitric acid with a volume ratio of 1:1, add 30 grams of urea and 10.0 grams of hydrochloric acid solution with a concentration of 36.5% by mass, stir for 1 hour, then add 30 grams of kerosene and stir for 1 hour, The drop ball is formed in the oil ammonia column. The wet bulb was solidified in ammonia water with a concentration of 6.0% by mass for 1 hour, then filtered, washed 2 to 3 times with deionized water, dried at 60°C for 6 hours, and at 120°C for 10 hours, and then dried in dry air at 700 / 1 The gas / solid volume ratio was calcined at 600° C. for 4 hours to obtain the gamma-alumina carrier.

[0049] (2) Pr...

example 2

[0053] The catalyst was prepared according to the method of Example 1, except that the impregnating liquid used for impregnating the gamma-alumina carrier contained 0.1 mass % of Sn. The content of the active components of the prepared catalyst B was shown in Table 1.

example 3

[0055] The catalyst was prepared according to the method of Example 1, except that the impregnating solution used for impregnating Sn-containing alumina contained 1.8% by mass of Ir. The active component content of the prepared catalyst C was shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com