Anti-carbon-formation chromium-based catalyst for preparing propylene from propane through oxydehydrogenation, and preparation method and application thereof

A carbon-deposited chromium-based propane and catalyst technology, applied in the field of chemical catalysis, can solve problems such as poor stability and deactivation, and achieve the effects of increased catalyst life, high propylene selectivity, enhanced stability and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

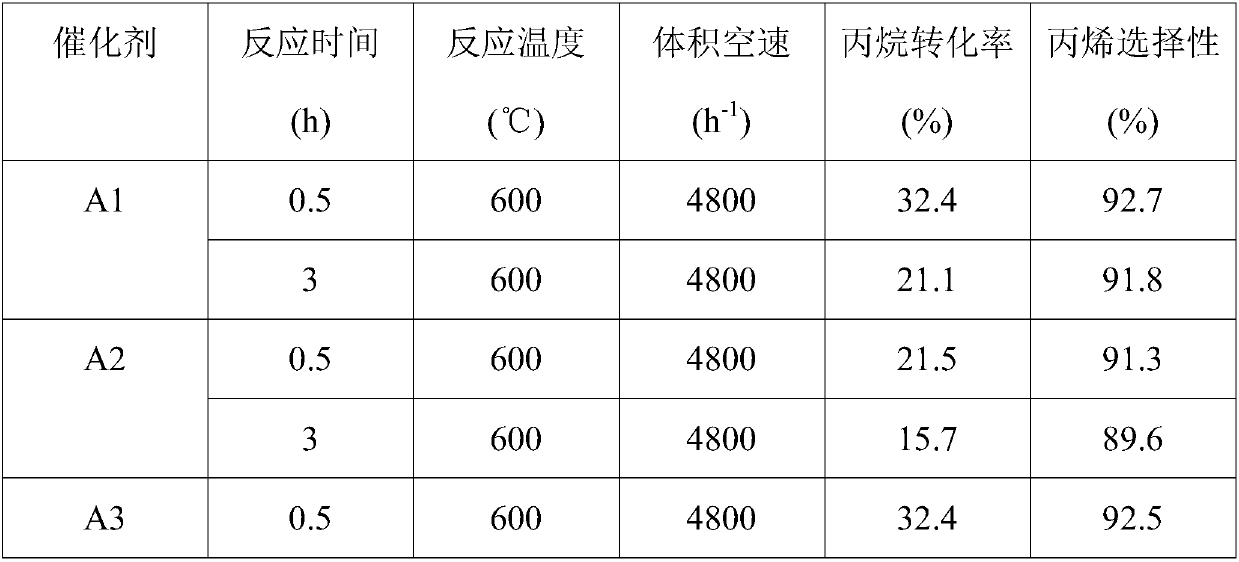

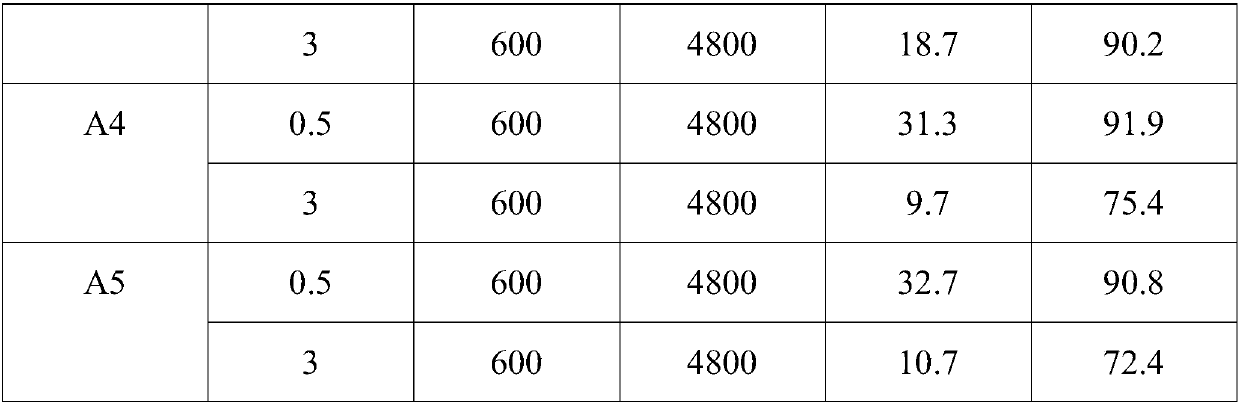

Embodiment 1

[0021] Al with rich unsaturated coordination Al 3+ (Pentacoordination) [ZL201110196192.4] Rod-shaped alumina is used as a carrier, and 129.5gCr(NO 3 ) 3 9H 2 O; 4.38g KNO 3 ; 0.74gCa(NO 3 ) 2 Prepare 200ml solution, immerse shaped alumina in the solution for 50min; remove surface moisture; 600 DEG C muffle furnace roasting 5h; Catalyst (A1) is mixed with 20vol% H at 600 DEG C 2 / N 2 Restoration for 2 hours, only pass through C during the test 3 h 8 . 18%Cr 2 o 3 -1.5%K 2 O-0.14%CaO / Al 2 o 3 , and the evaluation results are shown in Table 1.

Embodiment 2

[0023] Al with rich unsaturated coordination Al 3+ (Pentacoordination) [ZL201110196192.4] Rod-shaped alumina is used as the carrier, and 81.4gCr(NO 3 ) 3 9H 2 O; 2.75g KNO 3 ; 0.46gCa(NO 3 ) 2 Prepare 200ml solution, immerse shaped alumina in the solution for 50min; remove surface moisture; 600 DEG C muffle furnace roasting 5h; Catalyst (A2) is mixed with 20vol% H at 600 DEG C 2 / N 2 Restoration for 2 hours, only pass through C during the test 3 h 8 . 10%Cr 2 o 3 -1.5%K 2 O-0.14%CaO / Al 2 o 3 , and the evaluation results are shown in Table 1.

Embodiment 3

[0025] Al with rich unsaturated coordination Al 3+ (Pentacoordination)【ZL201110196192.4】Rod-shaped alumina is used as the carrier, and 146.6gCr(NO 3 ) 3 9H 2 O; 4.96g KNO 3 Prepare 200ml solution, dip shaped alumina in the solution for 50min; remove surface moisture; 600 DEG C muffle furnace roasting 5h; Catalyst (A3) is mixed with 20vol% H at 600 DEG C 2 / N 2 Restoration for 2 hours, only pass through C during the test 3 h 8 . 18%Cr 2 o 3 -1.5%K 2 O-0.14%CaO / Al 2 o 3 , and the evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com