Catalyst for preparing p-xylene as well as preparation method and application thereof

A technology of paraxylene and catalyst, applied in the field of catalysis, to achieve the effects of slowing down deactivation, not easy to migrate, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

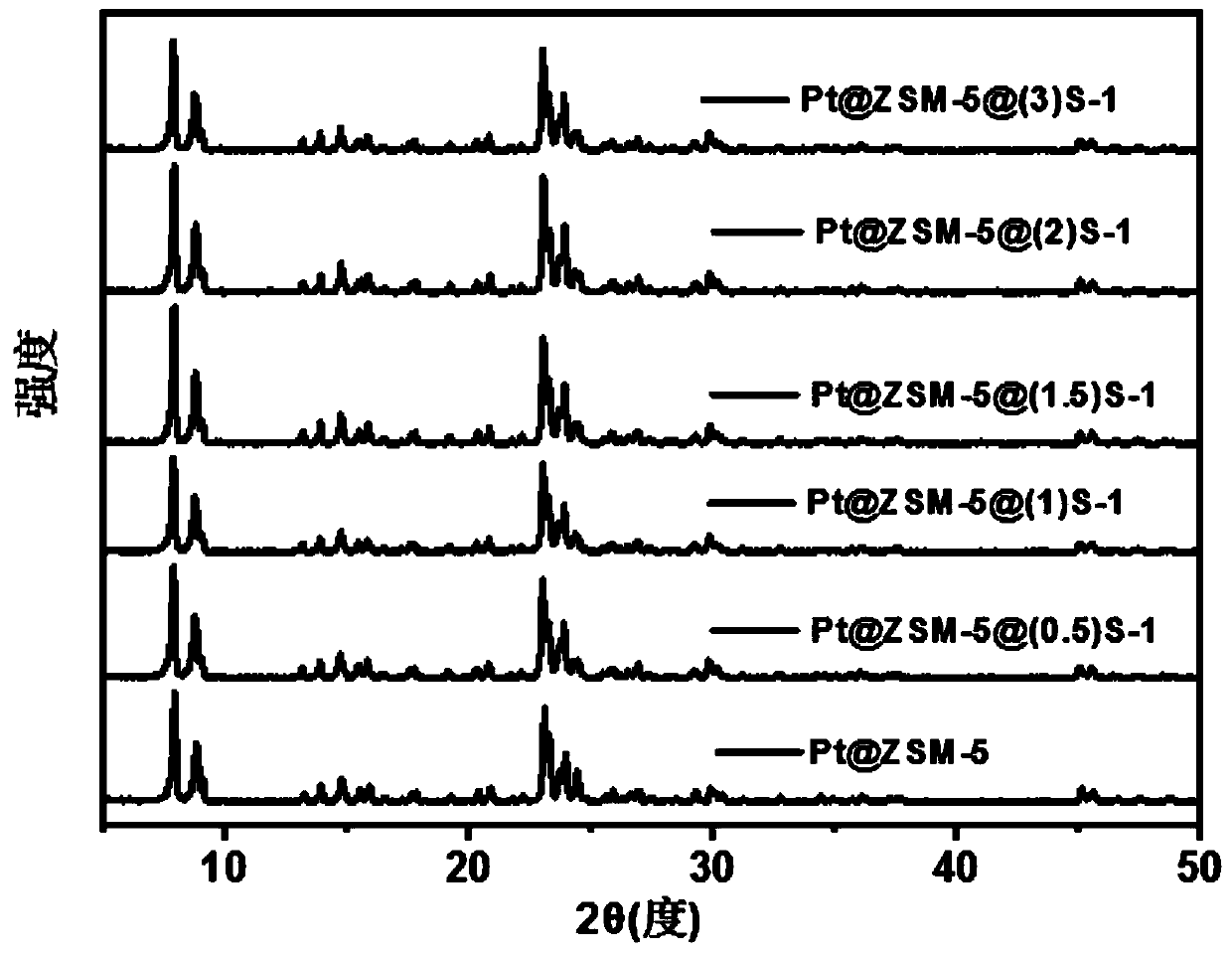

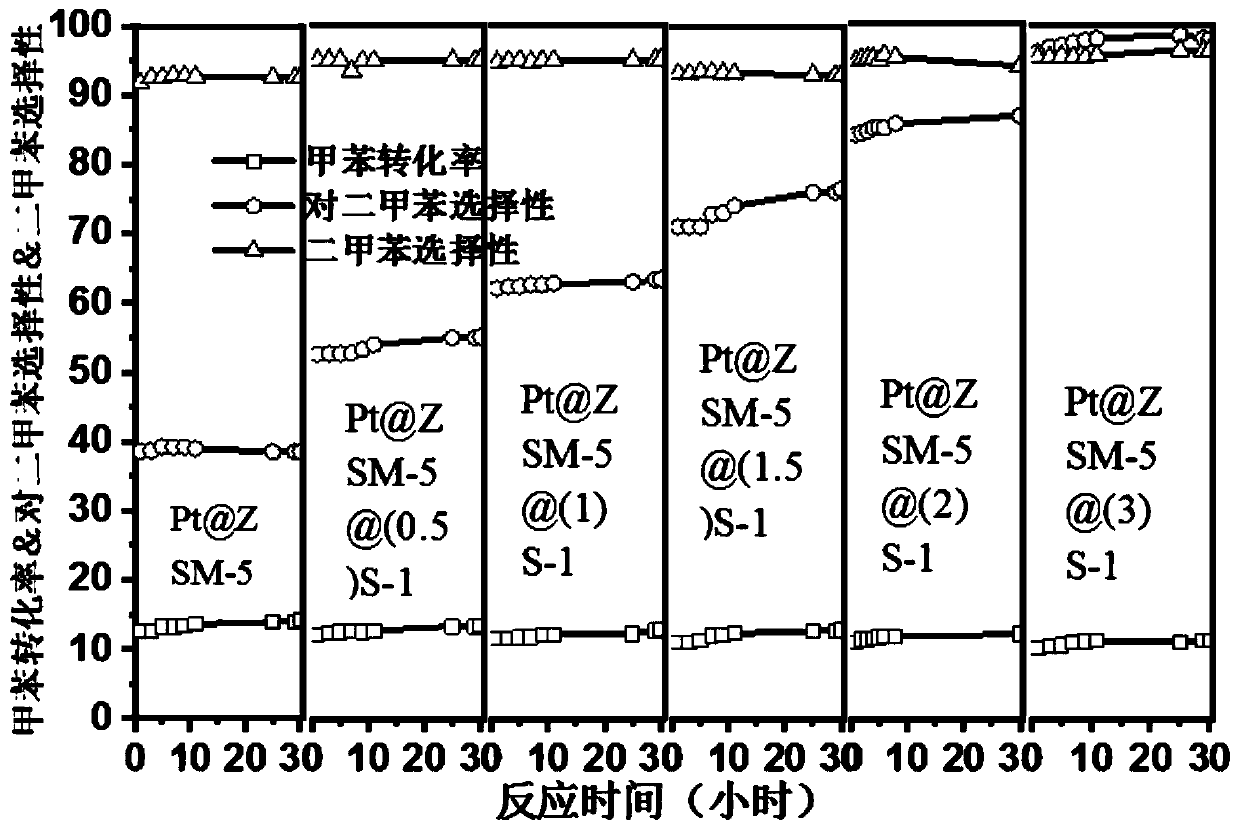

Embodiment 1

[0093] The core-shell mass ratio of the catalyst described in this embodiment is 1:0.51, the hydrogenation metal is Pt, and the mass percentage of the hydrogenation metal Pt in the catalyst is 0.016%; the preparation method of the catalyst comprises the following steps:

[0094] (1) Prepare the nuclear phase Pt@ZSM-5 molecular sieve, the preparation process includes the following steps:

[0095] (a) Add 10 g of ethyl orthosilicate and 26 g of tetrapropylammonium hydroxide into 10 g of deionized water at 35°C and stir for 10 min, marked as solution A;

[0096] (b) Dissolve 0.1332g of aluminum sulfate (the molar ratio of silica to alumina is 400) into 10g of deionized water, marked as solution B;

[0097] (c) Slowly add solution B dropwise to solution A, and continue stirring for 6 hours to obtain a mixed solution;

[0098] (d) Dissolving 0.0095g tetraammine platinum nitrate in 10.8g deionized water to obtain an aqueous hydrogenation metal source solution;

[0099] (e) Slowly ...

Embodiment 2

[0105] The core-shell mass ratio of the catalyst described in this embodiment is 1:1.08, the hydrogenation metal is Pt, and the mass percentage of hydrogenation metal Pt in the catalyst is 0.014%;

[0106] In the preparation process of the catalyst described in this example, the nuclear phase Pt@ZSM-5 molecular sieve prepared in Example 1 was used as a raw material, and an epitaxial growth was performed to form an S-1 molecular sieve to obtain the catalyst; the preparation method included the following steps:

[0107] (a') Mix 3.47g ethyl orthosilicate, 0.68g tetrapropylammonium hydroxide, and 52g water, stir and hydrolyze at 35°C for 7 hours to obtain a mixed solution;

[0108] (b') Add 1 g of the Pt@ZSM-5 powder prepared in Example 1 into the mixed solution obtained in step (a'), continue stirring for 1 h, and then transfer it to a 100 mL crystallization kettle with a polytetrafluoroethylene lining , crystallized in a rotary crystallization oven at 170°C at a speed of 20r / mi...

Embodiment 3

[0110] The core-shell mass ratio of the catalyst described in this embodiment is 1:1.51, the hydrogenation metal is Pt, and the mass percentage of hydrogenation metal Pt in the catalyst is 0.011%;

[0111] In the preparation process of the catalyst described in this example, the nuclear phase Pt@ZSM-5 molecular sieve prepared in Example 1 was used as a raw material, and an epitaxial growth was performed to form an S-1 molecular sieve to obtain the catalyst; the preparation method included the following steps:

[0112] (a') Mix 5.21g ethyl orthosilicate, 1.02g tetrapropylammonium hydroxide, and 52g water, and stir and hydrolyze at 35°C for 7 hours to obtain a mixed solution;

[0113] (b') Add 1 g of the Pt@ZSM-5 powder prepared in Example 1 into the mixed solution in step (a'), continue stirring for 1 h, then transfer to a 100 mL crystallization kettle with a polytetrafluoroethylene liner, at 170 ℃ Rotary crystallization oven at 20r / min for 72 hours of crystallization. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com