Metal-modified MFI@MFI core-shell molecular sieve catalyst and preparation thereof

A technology of metal modification and molecular sieve, applied in the direction of molecular sieve catalysts, including molecular sieve catalysts, catalysts, etc., can solve the problems of short diffusion channels, high density of strong acids, and fast deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

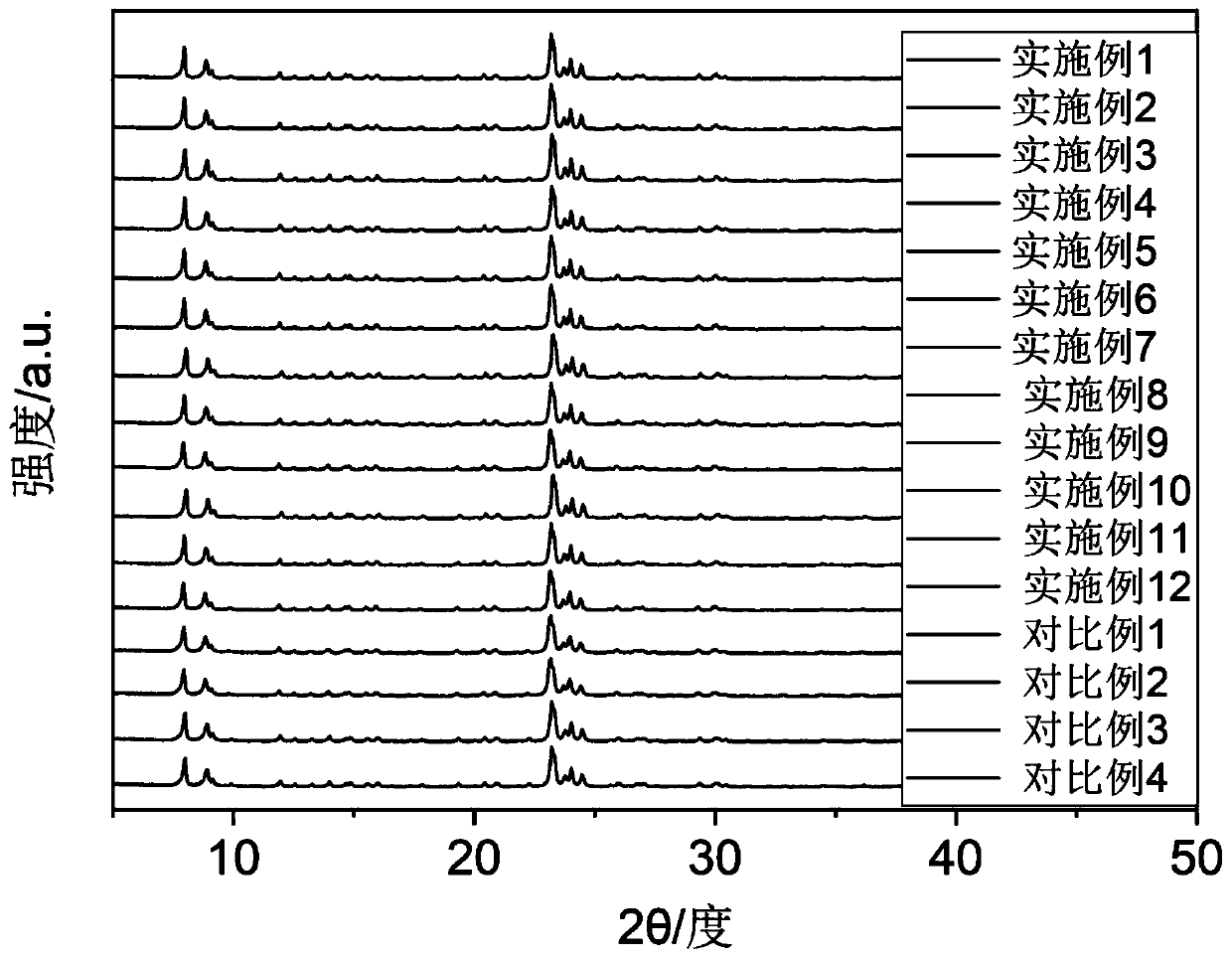

[0065] 0.2g of Mn with a particle size of 20±10nm 2 o 3 Nano-metal oxides, 2g N-(2-aminoethyl)-3-aminopropyltrimethoxysilane, 10g hydrogen silicon aluminum than 200 small grain ZSM-5 molecular sieves are put into 20g methanol, fully stirred for 3h, and then Transfer to a high-temperature-resistant stainless steel kettle, solvent heat treatment at 270°C for 12h, and then dry at 140°C for 10h to obtain Mn 2 o 3 Modified small grain ZSM-5 molecular sieve. Add 0.12 g boric acid, 12.18 g tetrapropylammonium hydroxide (25%), 47.82 g deionized water, 2.2 g Mn 2 o 3 Modified small-grain ZSM-5 molecular sieve, 20g of tetraethyl orthosilicate, stirred for 180min at a stirring rate of 180r / min, then transferred the prepared crystallization solution into a high-pressure stainless steel kettle, and crystallized at 180°C for 72h. The obtained product is suction filtered and dried to obtain catalyst powder. The obtained catalyst XRD pattern is as follows figure 1 As shown, the SEM ima...

Embodiment 2

[0067] 0.3g of MnO with a particle size of 30±10nm 2 Nano metal oxide (SEM image as image 3 Shown), 1g N-aminoethyl-3-aminopropylmethyldimethoxysilane, 10g hydrogen-type silicon aluminum ratio 300 nanometer thin layer ZSM-5 molecular sieve are put into 40g n-hexane, fully stirred for 2h, and then transferred to put into a high-temperature-resistant stainless steel kettle, solvent heat treatment at 220 ° C for 8 h, and then dry at 100 ° C for 20 h to obtain MnO 2 Modified nano thin layer ZSM-5 molecular sieve. Add 16.24g tetrapropylammonium hydroxide (25%), 36.62g deionized water, 3.2g MnO 2 Modified nano thin layer ZSM-5 molecular sieve, 20g of silica sol (SiO 2, 40%), stirred for 300min, and the stirring rate was 120r / min, then transferred the prepared crystallization solution into a high-pressure stainless steel kettle, crystallized at 170°C for 48h, and obtained the product through suction filtration and drying to obtain catalyst powder . The obtained catalyst XRD pat...

Embodiment 3

[0069] 0.4g of CeO with a particle size of 40±20nm 2 Nano-metal oxides, 1g N-(2-aminoethyl)-3-aminopropyltrimethoxysilane, 10g hydrogen-type silicon aluminum ratio 400 nanocrystalline stacked ZSM-5 molecular sieves are put into 30g toluene, fully stirred for 4h, and then Transfer to a high-temperature resistant stainless steel kettle, solvent heat treatment at 210°C for 24h, and then dry at 120°C for 20h to obtain CeO 2 Modified nanocrystalline stacked ZSM-5 molecular sieve. Add 6.48g tetrapropylammonium bromide, 36.62g deionized water, 3g CeO to the beaker 2 Modified nanocrystalline stacked ZSM-5 molecular sieve and 10g of coarse-pore silica gel were stirred for 240min at a stirring rate of 360r / min, then the prepared crystallization solution was transferred to a high-pressure stainless steel kettle, and crystallized at 160°C for 96h to obtain The product is suction filtered and dried to obtain catalyst powder. The obtained catalyst XRD pattern is as follows figure 1 show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com