Oil-resistant weather-resistant thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic elastomer and polyurethane technology, applied in the field of elastomer and its preparation, can solve the problems of loss of original performance, lower oil quality, cracking of elastomer, etc., achieve excellent oil resistance and weather resistance, and low oil colloid content , the effect of good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the oil-resistant and weather-resistant polyurethane thermoplastic elastomer of the present invention comprises the following steps:

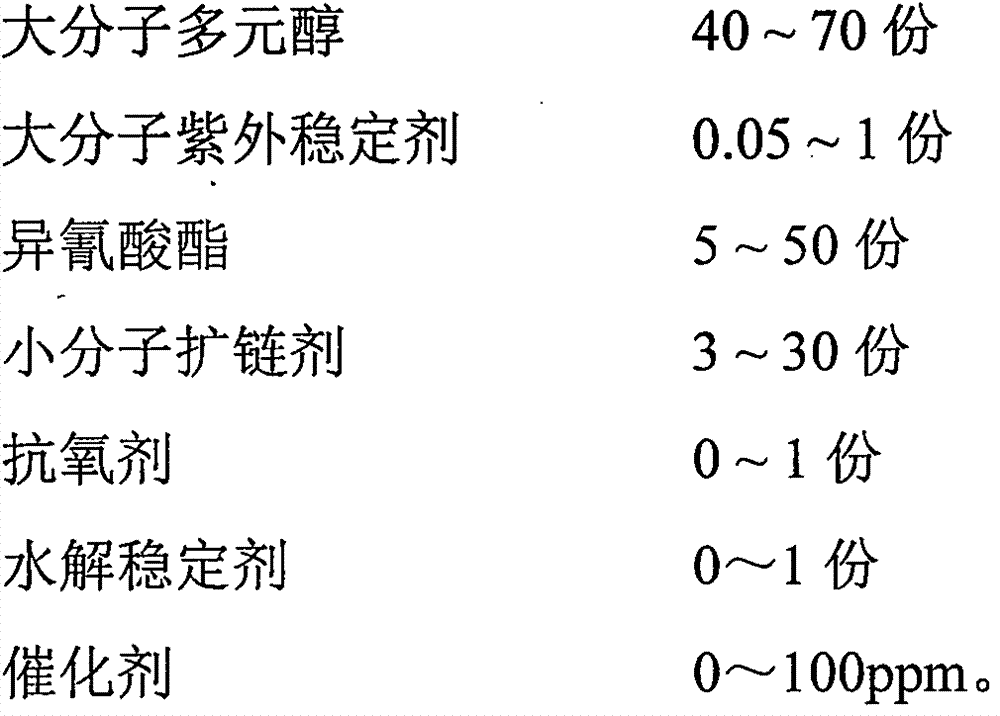

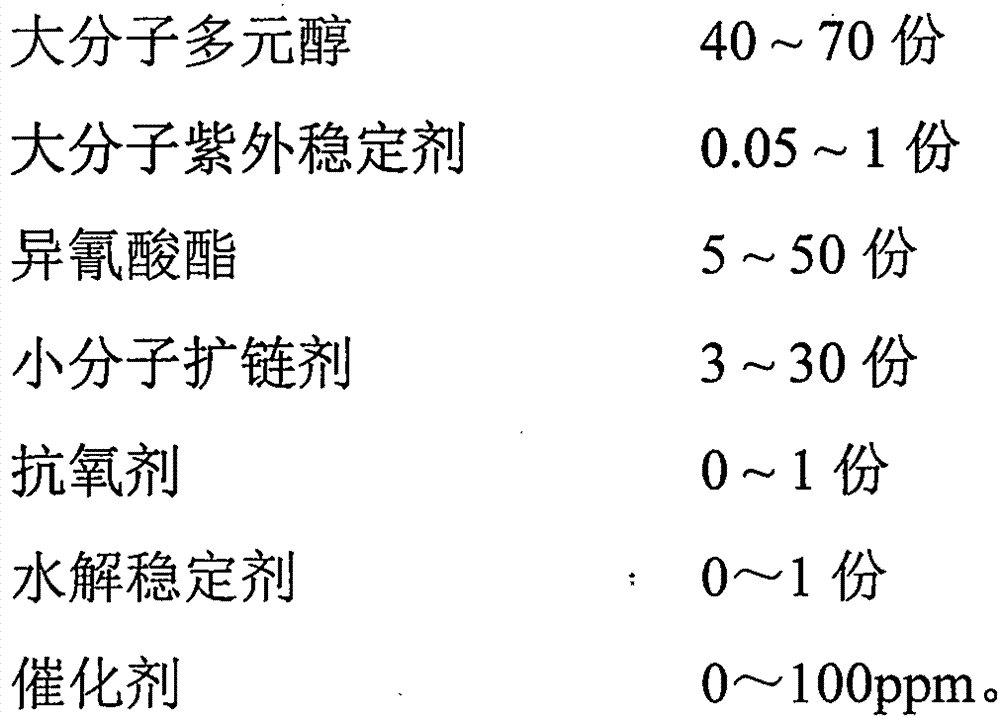

[0033] Step 1, weighing 40-70 parts of macromolecular polyol, 3-30 parts of small molecule chain extender, 0.05-1 part of macromolecular UV stabilizer, 0-1 part of antioxidant, 0-1 part of hydrolysis stabilizer, 0-100 parts per million concentration of catalyst, respectively placed at 30-150 ° C for 2-4 hours of dehydration;

[0034] Step 2, add the melted and dehydrated macromolecular polyol, small molecule chain extender and 5-50 parts of isocyanate melted at 50-120°C into the twin-screw reaction extruder for reaction, and simultaneously add macromolecular ultraviolet stabilizer, Antioxidant, hydrolysis stabilizer, catalyst, extrusion temperature is 130~250℃;

[0035] Step 3, in the twin-screw reaction extruder, the melt of the mixture is melted and fully mixed, and pelletized under water to obtain thermoplas...

Embodiment 1

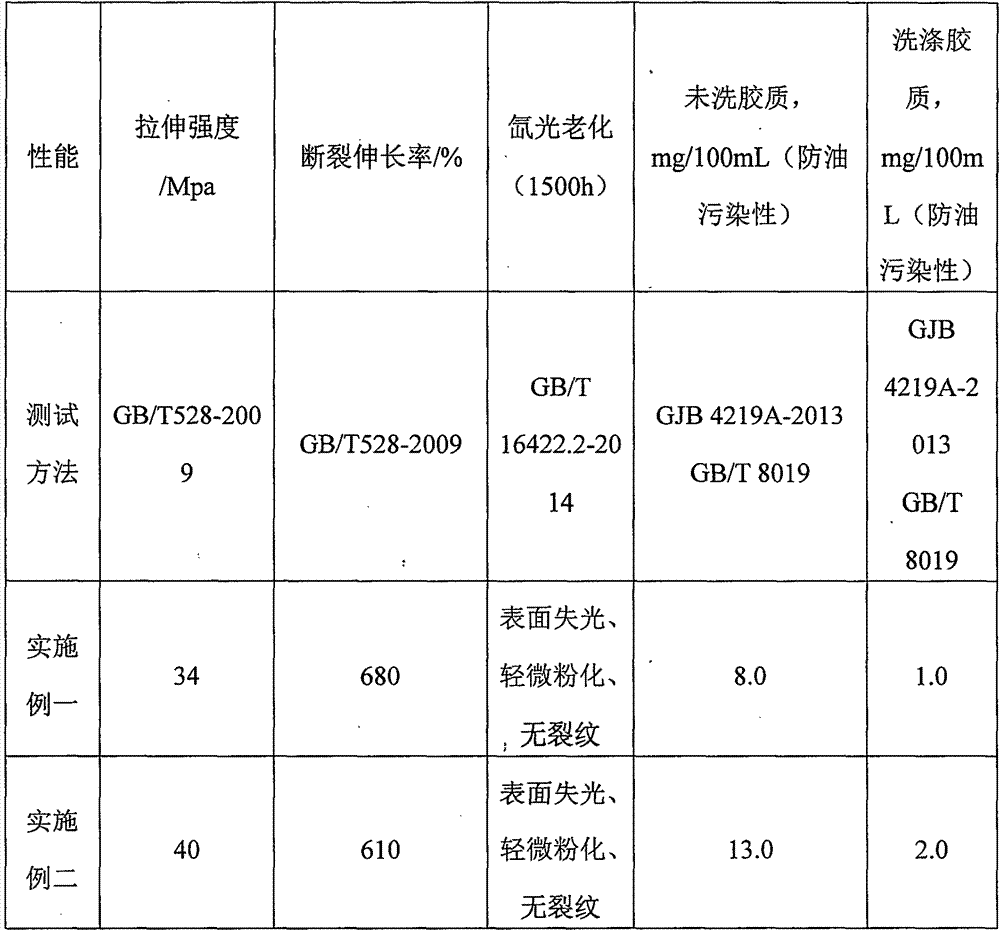

[0038]The present invention proposes an oil-resistant and weather-resistant polyurethane thermoplastic elastomer. The raw materials are obtained by weight ratio: 40 parts of polybutylene adipate diol, 5 parts of diphenylmethane diisocyanate, 3 parts of 1,4-butanediol, 0.05 parts of 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl)-5-octyloxyphenol, 0.2 parts of antioxidant 1010, 0.2 parts of carbodiimide, 20 ppm of dibutyltin dilaurate.

[0039] The weighed polybutylene adipate diol, 1,4-butanediol, 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5- Triazin-2-yl)-5-octyloxyphenol, antioxidant 1010, carbodiimide, and dibutyltin dilaurate were dehydrated at 30°C for 4 hours, and polybutylene adipate di Alcohol, 1,4-butanediol and diphenylmethane diisocyanate melted at 50°C are added to the twin-screw reaction extruder for reaction, and macromolecular UV stabilizers, antioxidants, hydrolysis stabilizers, and catalysts are added at the same time , the extrusion temperature is 200°C; the mix...

Embodiment 2

[0041] The present invention proposes an oil-resistant and weather-resistant polyurethane thermoplastic elastomer. Raw materials are obtained by weight ratio: 45 parts of polytetrahydrofuran ether glycol, 15 parts of p-phenylene diisocyanate, 10 parts of 1,3-propylene glycol, 1 part of bis(1,2,2 , 6,6-pentamethyl-4-piperidinyl) sebacate, 0.3 parts of antioxidant 1520, 50 ppm stannous octoate.

[0042] The weighed polytetrahydrofuran ether glycol, 1,3-propylene glycol, bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate, antioxidant 1520, octanoic acid The stannous was dehydrated at 50°C for 3.5 hours, polytetrahydrofuran ether glycol, 1,3-propanediol and p-phenylene diisocyanate melted at 60°C were added to the twin-screw reaction extruder for reaction. (1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate, antioxidant 1520, stannous octoate, the extrusion temperature is 180°C; in a twin-screw reaction extruder The mixture was melted and mixed thoroughly, and pelletized under water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com