Method for improving hydrogenation production of gasoline and diesel oil by coal tar

A technology for coal tar, gasoline and diesel, which is applied in the field of improving the hydrogenation of coal tar to produce gasoline and diesel, can solve the problems of low added value, low yield of gasoline and diesel, environmental pollution, etc. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

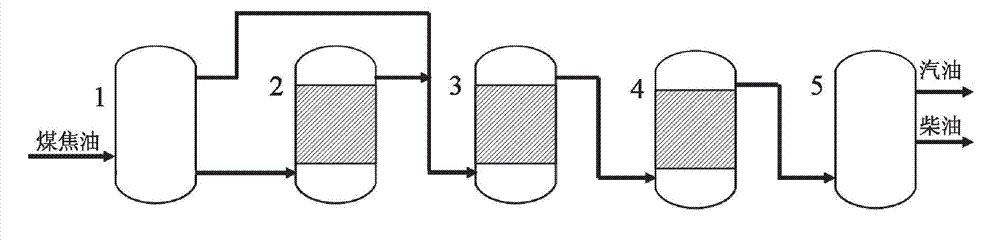

Method used

Image

Examples

Embodiment 1

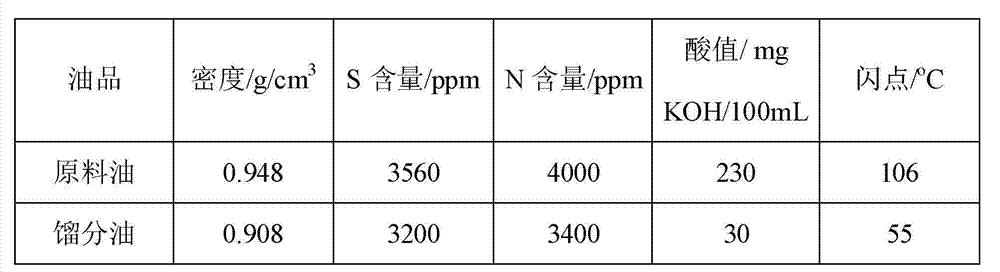

[0019] Embodiment 1: Coal tar is divided into light oil (o C) and heavy oil (o C). The following table 1 sees the atmospheric distillation mass balance test results

[0020]

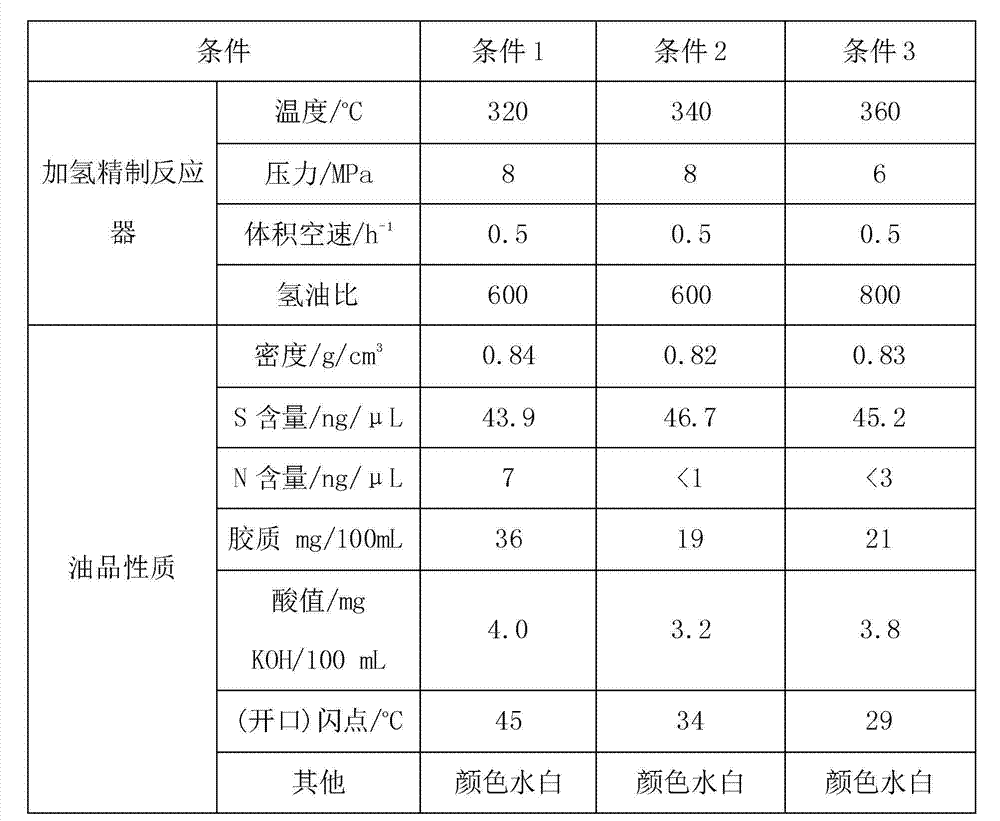

Embodiment 2

[0021] Embodiment 2: heavy oil (o C) Light oil is obtained after delayed coking. See Table 2 below for delayed coking material balance test results

[0022]

Embodiment 3

[0023] Example 3: Gas-phase catalytic cracking of coal tar over a molecular sieve / alumina catalyst. After delayed coking, heavy oil is mixed with light oil and injected into a reactive distillation column equipped with molecular sieve / alumina catalyst for catalytic distillation. The catalyst is composed of alumina containing 35% ZSM-48 and 15% mordenite. A columnar product of 2.0-3.0 mm in length, 3-8 mm in length, 0.65-0.80 g / mL in bulk density, and greater than 40 N / mm in strength can be obtained by bonding molding. The waste residue and gas generated during the coal tar conversion process are used for heating, and the agent-oil ratio is controlled between 1-20. The gas produced is used to heat the distillation column. The following table 2 sees the catalytic distillation mass balance test results

[0024]

Catalyst adsorption

Charcoal residue

gas + loss

Mass / g

1800

27

14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com