Novel mould vibrating brick making machine

A brick making machine, a new type of technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of low production output, low vibration efficiency, unsatisfactory vibration force, etc., to achieve smooth and beautiful blank surface, consistent movement, vibration good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

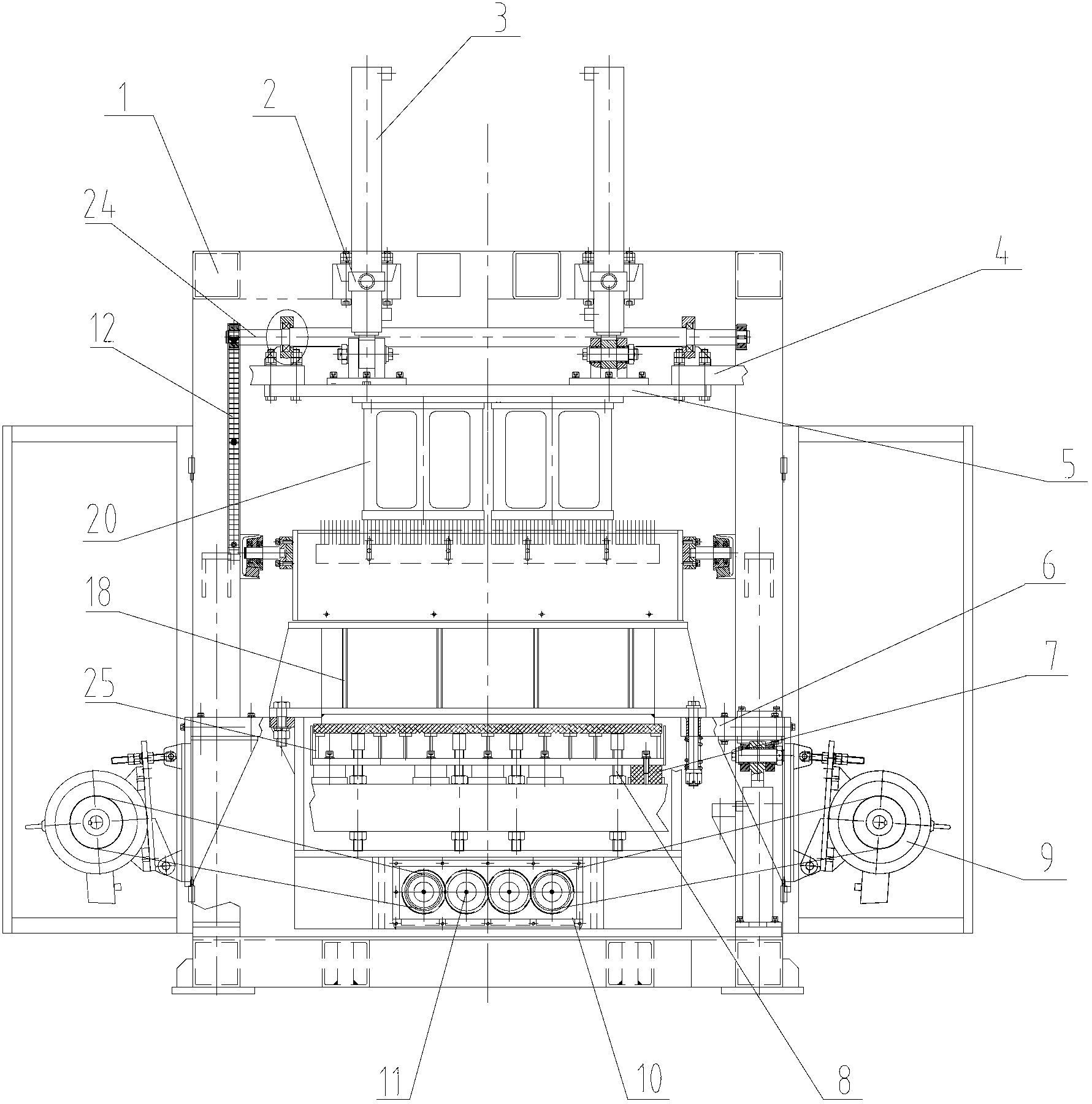

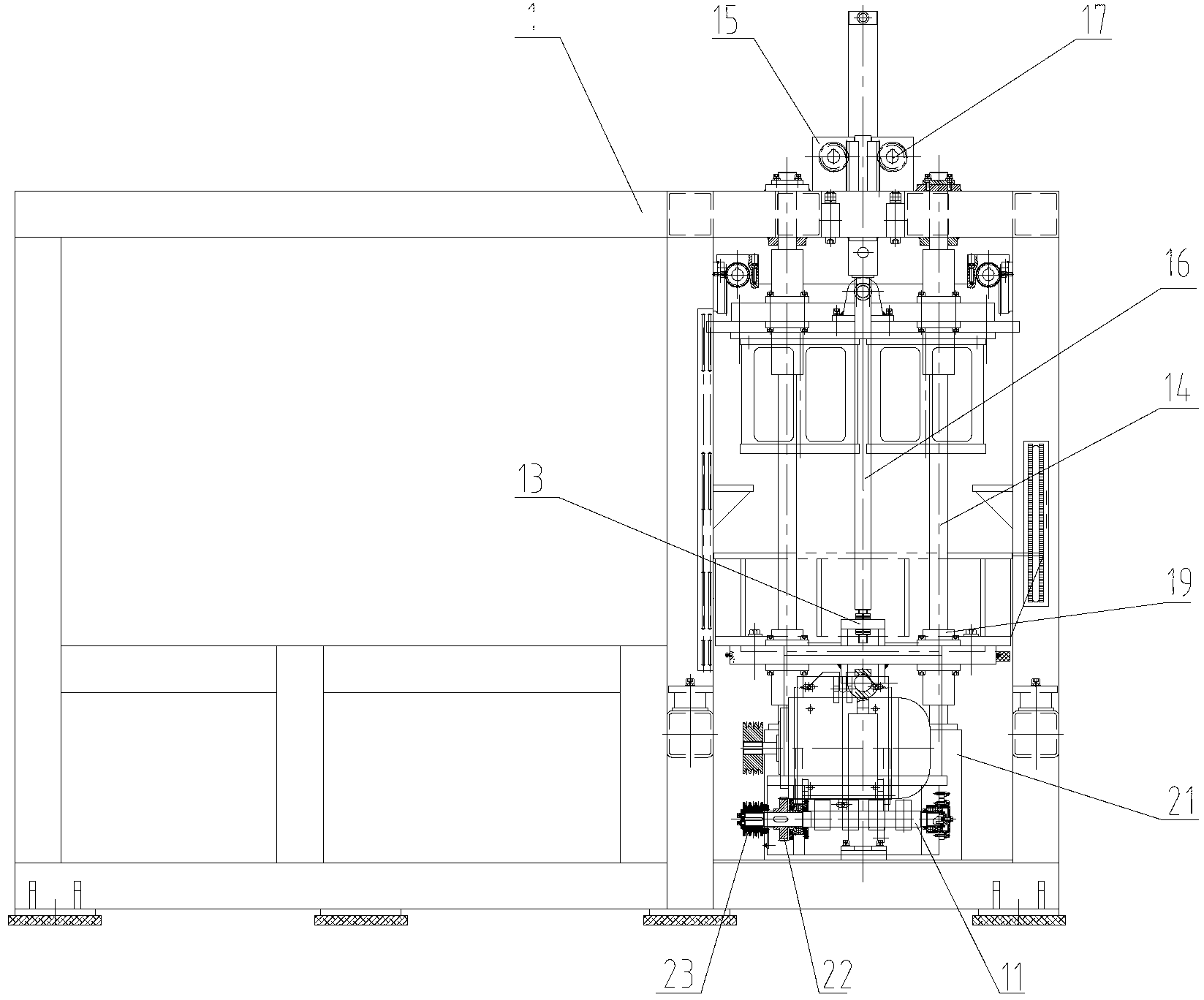

[0016] The new mold vibration brick making machine proposed by the present invention includes a main machine and supporting devices, and the supporting devices described here include a storage hopper, a feeder, a plate feeding mechanism, a material distribution mechanism, a brick discharging machine, a stacker, a hydraulic station and a complete machine. automatic control device. The main engine is mainly composed of eight parts such as the main frame 1, the upper moving mechanism, the column part, the lower moving mechanism, the vibration mechanism 10, the pallet platform 25, the lower balancing mechanism 15 and the power unit 9. figure 1 , figure 2 Shows the main structure of the host, where:

[0017] Main frame 1 is made of upper beam, column and lower beam, and main frame 1 is provided with upper die oil cylinder seat 2, upper die synchronous rack 12 and the bearing seat etc. of lower die synchronous shaft 17.

[0018] Upper moving mechanism mainly is made up of upper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com