System for preparing steel slag sintered bricks

A technology of sintered bricks and steel slag, applied in the field of sintered steel slag bricks, can solve the problems of insufficient strength, water source, atmospheric environment pollution, poor water permeability, etc., and achieve the effects of increasing porosity, facilitating hydration hardening, and improving compact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

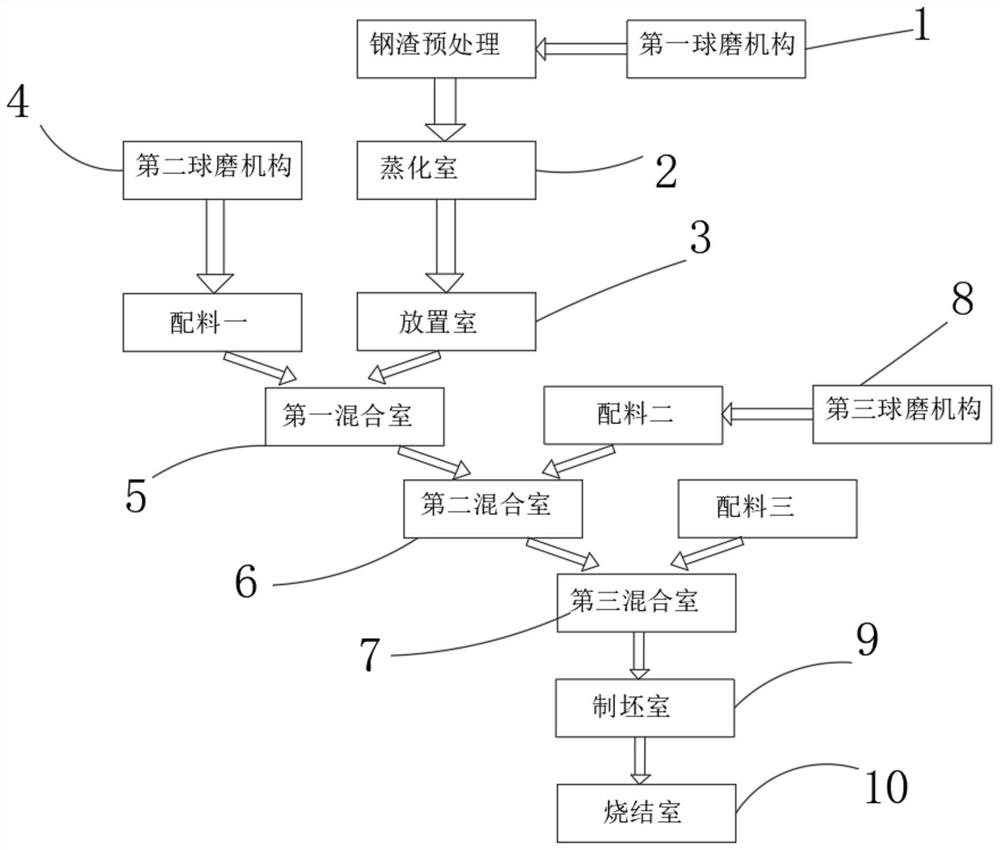

[0047] Such as figure 1 Shown, a kind of system of preparing steel slag sintered brick comprises:

[0048] The first ball milling mechanism 1, the first ball milling mechanism 1 pretreats the steel slag, and grinds the steel slag to a steel slag powder of ≤0.045 mm;

[0049] The lower end of the first ball milling mechanism 1 is provided with a steaming chamber 2, and the steaming chamber 2 steams the ground steel slag powder to dry the water; put it into the storage chamber 3;

[0050] The second ball mill 4 mechanism grinds the ingredient 1, and the grinding fineness of the ingredient 1 is ≤650 mesh particle size;

[0051] A first mixing chamber 5 is provided at the lower end of the second ball mill 4 and the placement chamber 3, and the first mixing chamber 5 is used to mix the ingredient 1 with the steel slag powder;

[0052] The lower end of the first mixing chamber 5 is provided with a second mixing chamber 6, and the second mixing chamber 6 is used for mixing the firs...

Embodiment 2

[0065] A system for preparing steel slag sintered bricks, comprising the following steps:

[0066] Step Ⅰ: Pretreating the steel slag through the first ball mill mechanism, grinding the steel slag to a steel slag powder of ≤0.045mm;

[0067] Step Ⅱ: put the steel slag powder ground in step Ⅰ into the steaming chamber 2 for steaming treatment, and dry the water; put it into the storage chamber 3;

[0068] Step III: Grinding ingredient 1 by the second ball mill mechanism 4, said ingredient 1 is ground to a particle size of ≤650 mesh;

[0069] Step IV: mixing the steel slag powder in step II with ingredient 1 in step III in the first mixing chamber 5;

[0070] Step Ⅴ: Grinding the second ingredient by the third ball milling mechanism 8; mixing the mixture in the first mixing chamber 5 and the second mixing chamber 6 in the step IV;

[0071] Step VI: mix the mixture in the second mixing chamber 6 in step V with the ingredient three in the third mixing chamber 7;

[0072] Step V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com