Curvature radius adjustable prefabricated box-beam mold and construction method thereof

A construction method and a technology for adjusting the curvature are applied in the field of adjustable curvature radius molds to achieve the effects of improving production efficiency, reducing production costs, and having a smooth and beautiful surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

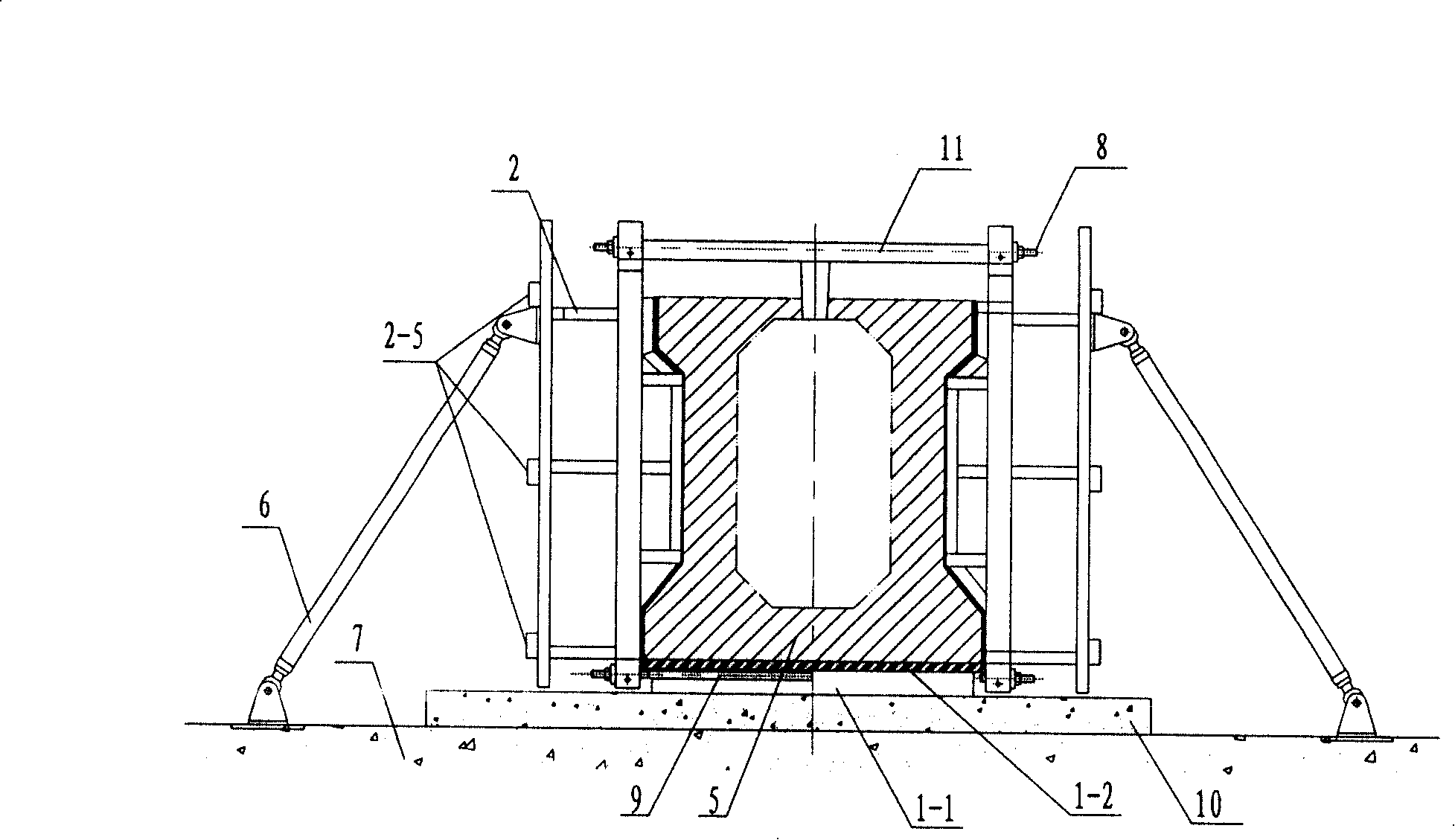

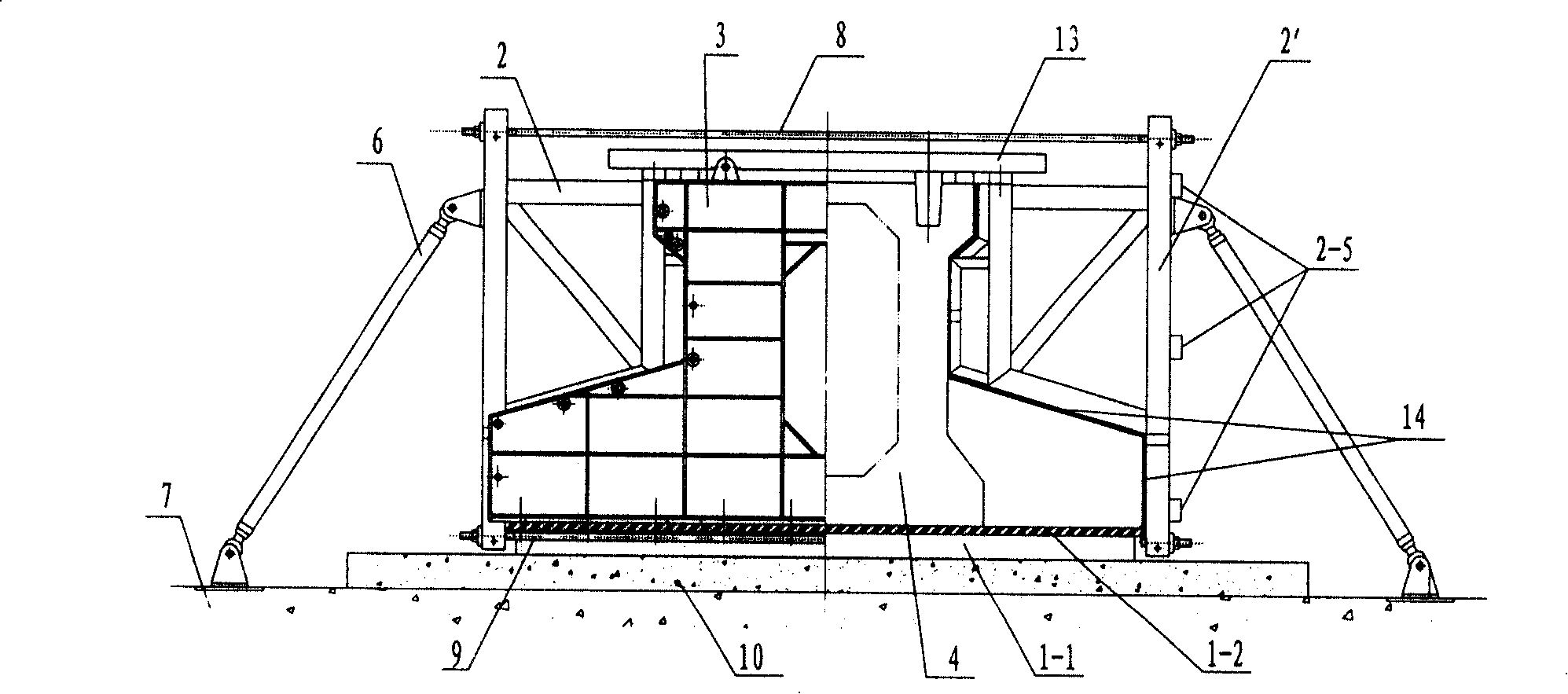

[0034] Such as figure 1 , figure 2 As shown, the adjustable radius of curvature prefabricated box girder mold of the present invention includes a bottom mold 1, a side mold and an end mold. side; the end mold includes a front mold 3 and a rear mold 3', which are respectively fixedly arranged at the front and rear ends of the bottom mold 1; Cavity 4;

[0035] The molds 2 and 2' on the left and right sides are fixedly connected to the floor 7 through the diagonal tie rods 6 respectively, and the molds on the left and right sides 2 and 2' are connected through the upper tie rod 8 connected to the upper part of the beam body and the lower part connected to the lower part of the bottom mold of the beam body. The pull rods 9 are fixedly connected to each other;

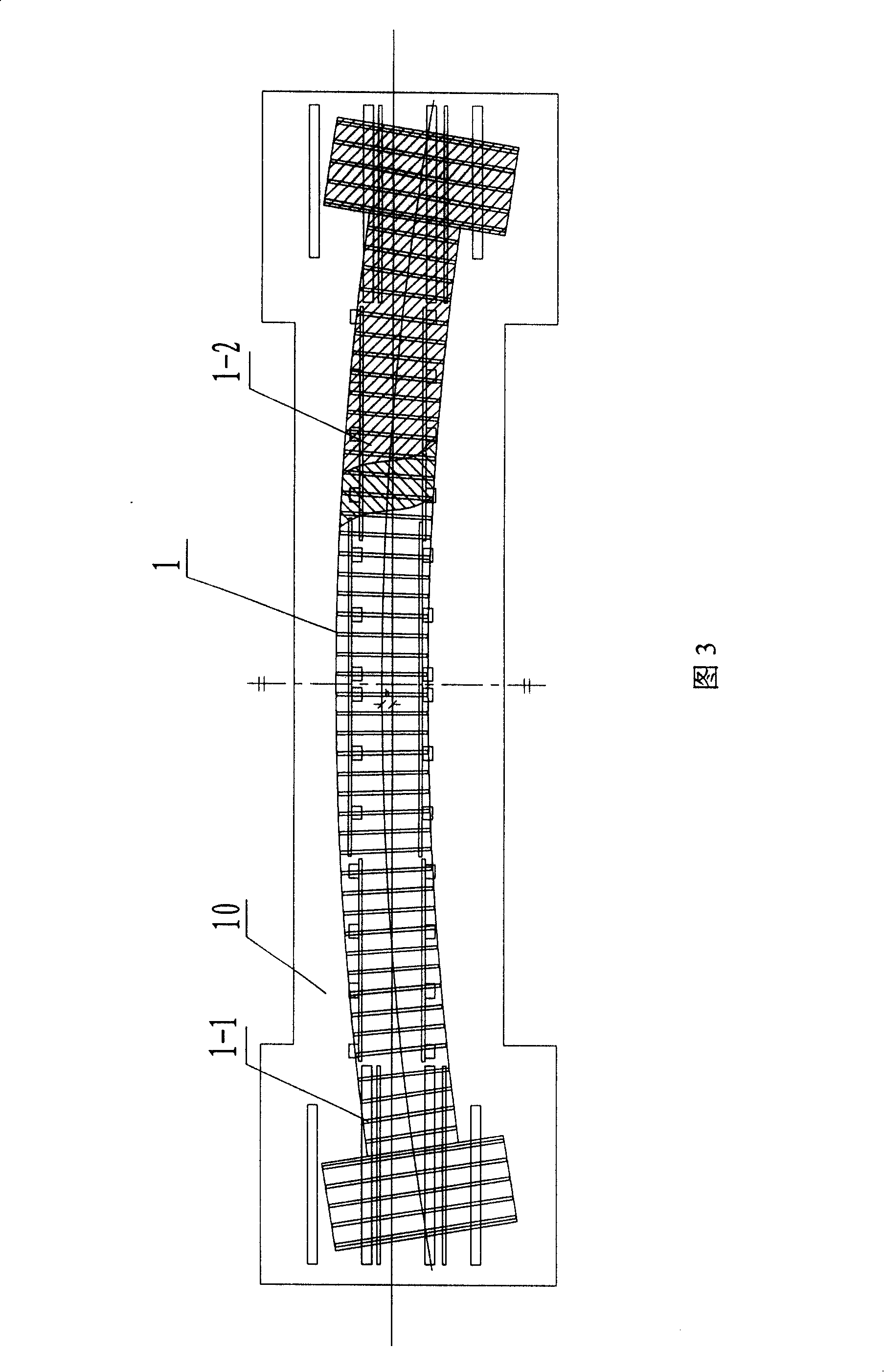

[0036] As shown in Figure 3, Figure 4 As shown, the bottom form 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com