Locating sleeve buried beforehand for electrical installation project

A technology for installation engineering and positioning sleeves, which is applied in the direction of electrical components, pipes, pipes/pipe joints/pipe fittings, etc. It can solve problems such as poor concrete pouring quality, uncontrollable verticality of pre-embedded pipes, and damage to formwork, etc., to achieve concrete Dense and solid, improve the success rate of pre-embedding, and save material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

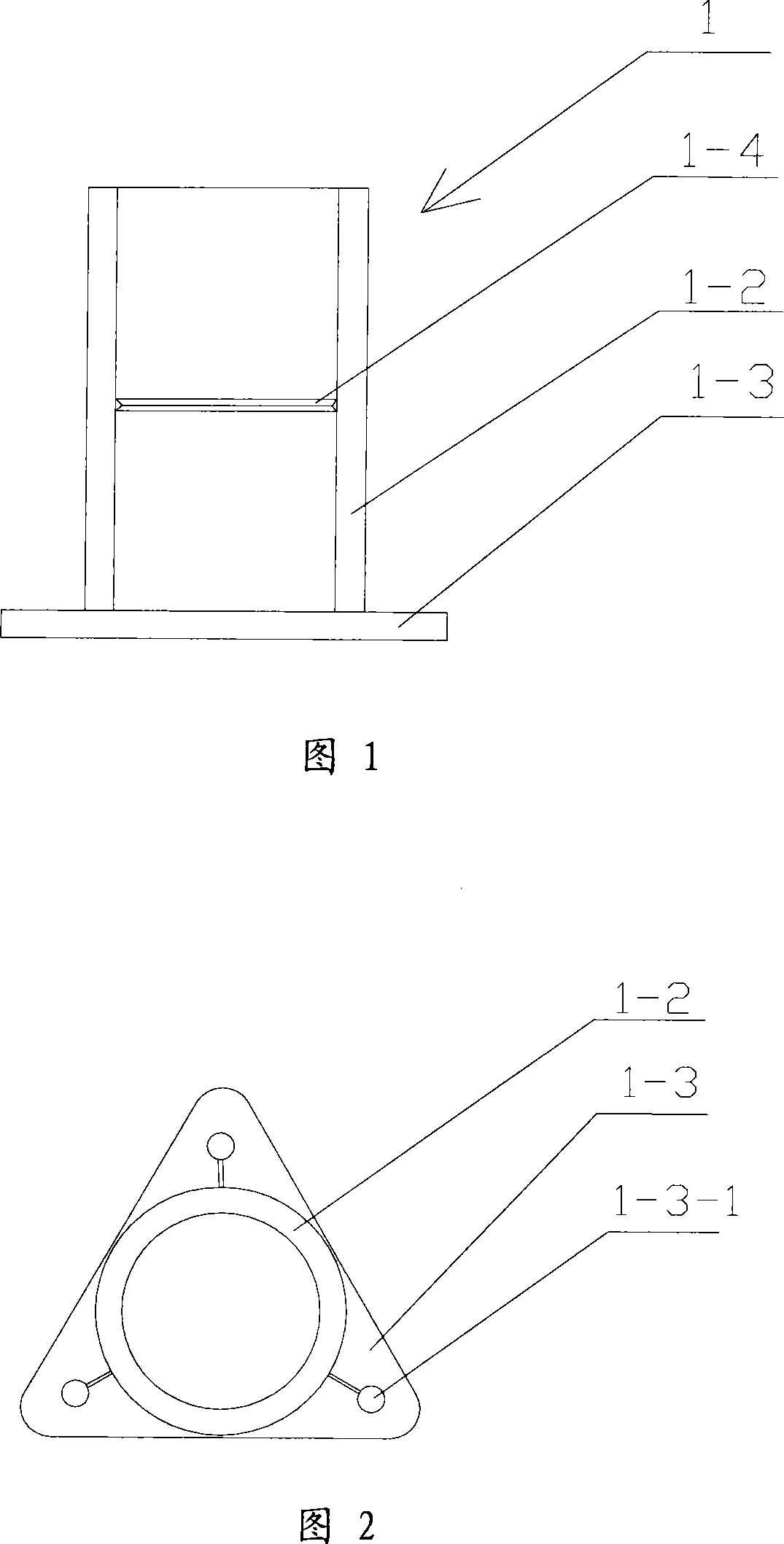

[0023] Embodiment 1, as shown in Figures 1 and 2, a special electrical installation project embedded positioning sleeve 1 in this embodiment includes a base 1-3 and a pipe body 1-2 on it, and the pipe body 1-2 is formed with a In the inner cavity suitable for the set of pre-embedded lines, there is a ring of stopper protrusions 1-4 on the inner cavity wall, the base 1-3 is triangular in shape, and each of its three corners has a screw hole 1-3-1 .

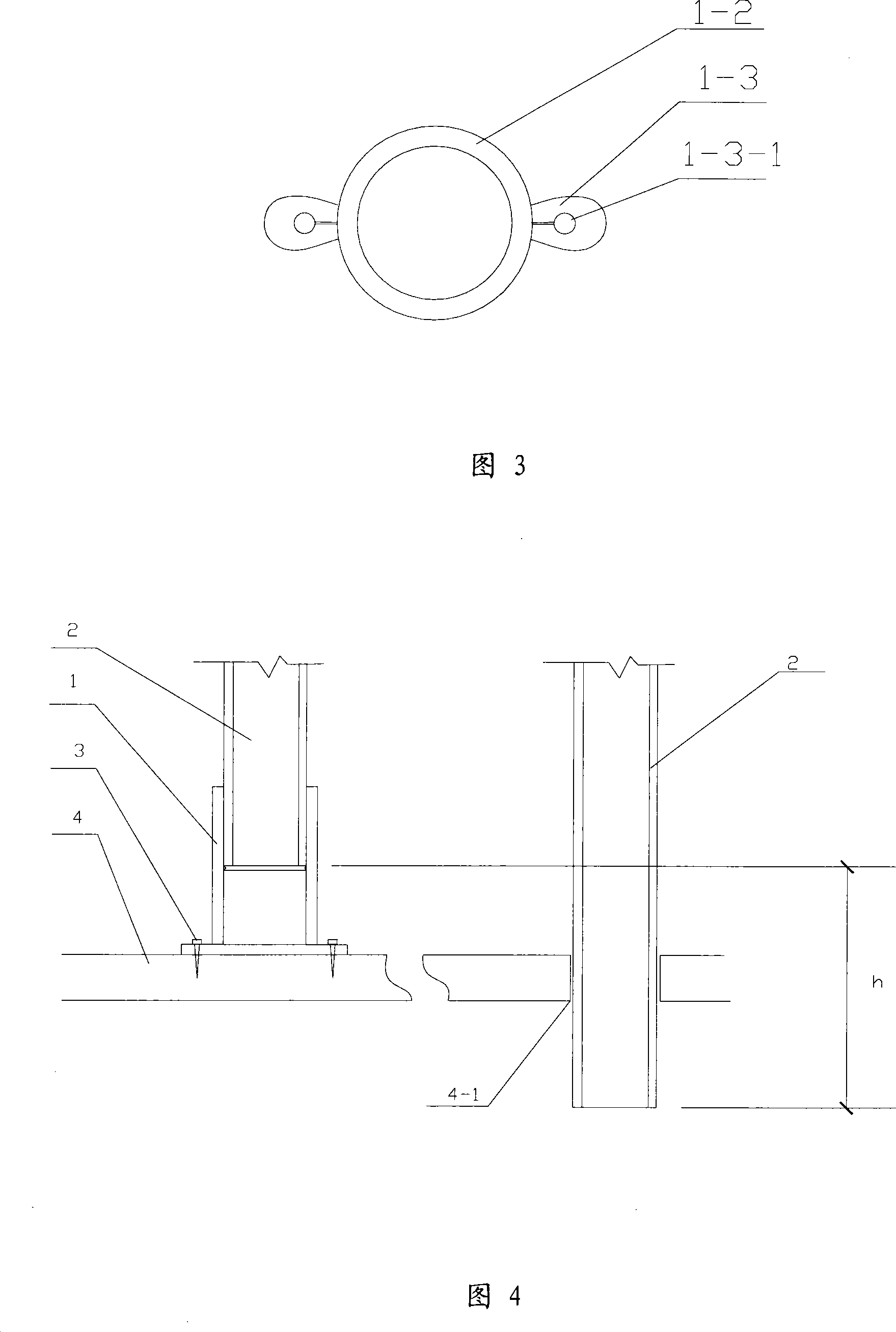

[0024] As shown in Fig. 4, the left picture in Fig. 4 is a reference picture of the use state of the present invention, and the right picture is a reference picture of the traditional tool use state. When in use, fix the pre-embedded positioning sleeve 1 of the electrical installation project to the position of the embedded line on the template 4 with screws, and then insert the pre-embedded line tube 2 into the upper inner cavity of the embedded positioning sleeve 1 of the electrical installation project , through the stopper pro...

Embodiment 2

[0026] Embodiment 2, as shown in Figure 3, differs from Embodiment 1 in that: the base 1-3 of this embodiment is two lugs, and the lugs are relatively arranged on the periphery of the pipe body, and there are screws on the lugs Hole 1-3-1. Of course, three lugs can also be provided, and the three lugs are distributed on the periphery of the pipe body at intervals of 120°, or four lugs can also be provided, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com