Friction stir welding device with adjustable stirring pin length and welding method

A technology of friction stir welding and needle stirring, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of limited welding depth, non-adjustable welding depth, unsatisfactory welding effect, etc. Good effect and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

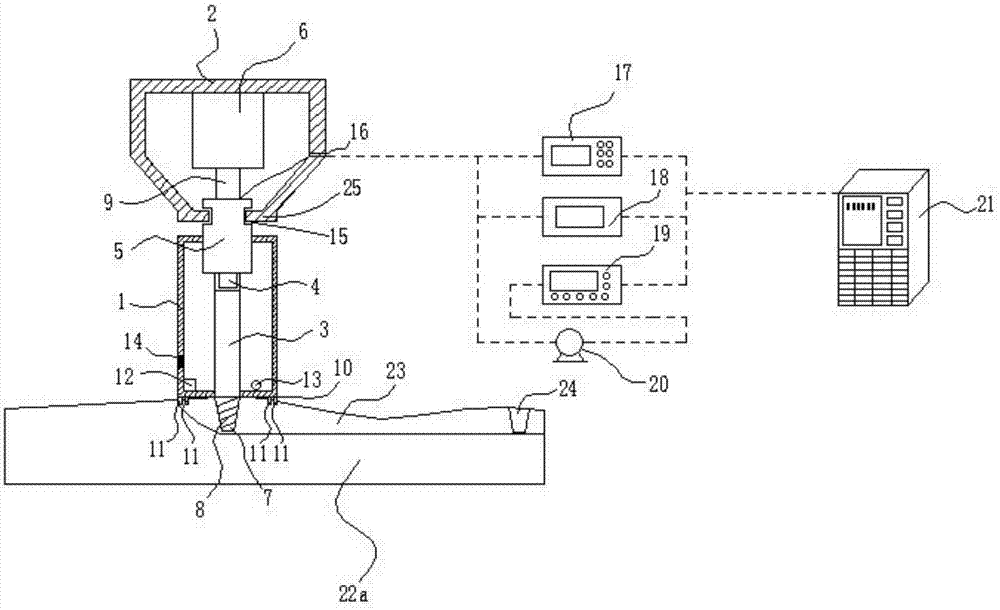

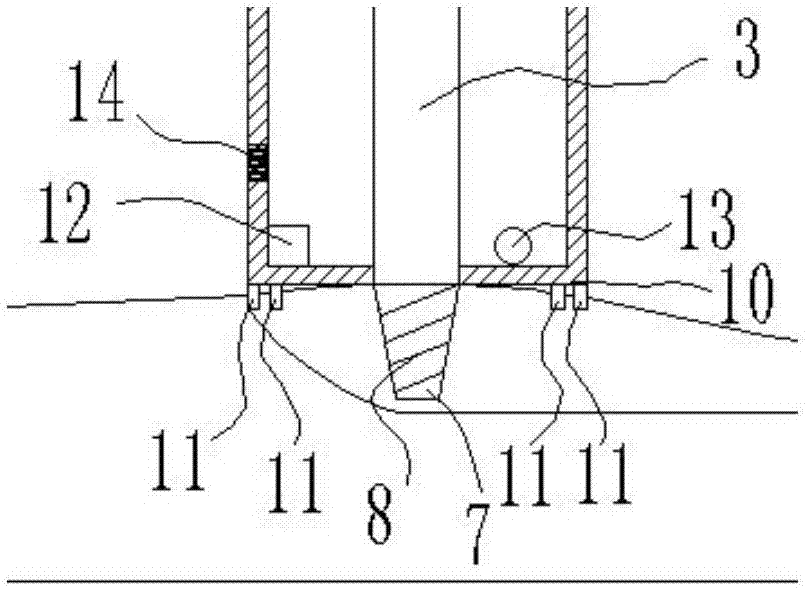

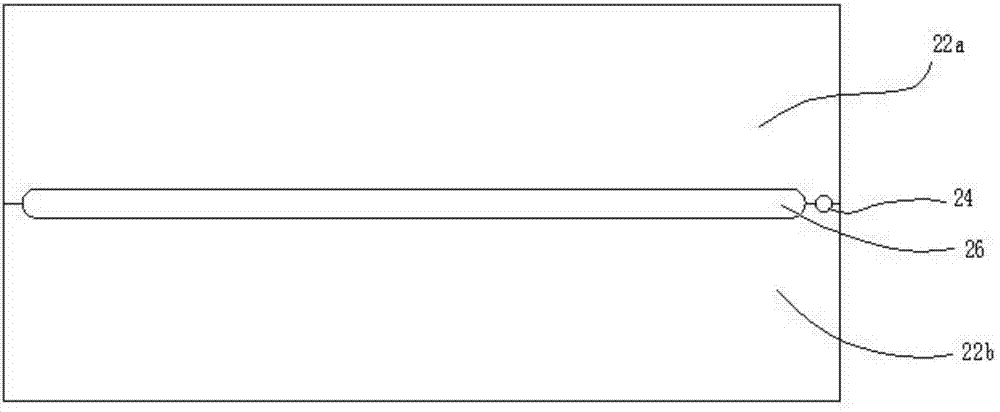

[0027] A friction stir welding device with adjustable length of stirring needle, said friction stir welding device with adjustable length of stirring needle comprises friction stir welding device main body 1, clamping part 2, miniature hydraulic cylinder 4, drive motor 6, temperature sensor 12 , an ultrasonic probe 13, an ultrasonic probe 17, a temperature display 18, a hydraulic control system 19, a hydraulic pump 20, and an operation controller 21, the friction stir welding device main body 1 is installed below the clamping part 2, and the stirring The main body 1 of the friction welding device is hollow inside, and a stirring needle 3 is provided inside. The hydraulic cylinder 4 can adjust and control the length of the stirring needle 3 through the miniature hydraulic cylinder 4. The inside of the clamping part 2 is hollow, and the driving motor 6 is arranged inside the clamping part 2. The driving motor 6 is connected by a drive shaft 9 To the stirring needle 3, the bottom...

Embodiment 2

[0033] A friction stir welding device with adjustable length of stirring needle, said friction stir welding device with adjustable length of stirring needle comprises friction stir welding device main body 1, clamping part 2, miniature hydraulic cylinder 4, drive motor 6, temperature sensor 12 , an ultrasonic probe 13, an ultrasonic probe 17, a temperature display 18, a hydraulic control system 19, a hydraulic pump 20, and an operation controller 21, the friction stir welding device main body 1 is installed below the clamping part 2, and the stirring The main body 1 of the friction welding device is hollow inside, and a stirring needle 3 is provided inside. The hydraulic cylinder 4 can adjust and control the length of the stirring needle 3 through the miniature hydraulic cylinder 4. The inside of the clamping part 2 is hollow, and the driving motor 6 is arranged inside the clamping part 2. The driving motor 6 is connected by a drive shaft 9 To the stirring needle 3, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com