Elastoplastic device for expansion joints in buildings and road engineering

A technology of road engineering and expansion joints, which is applied in the direction of buildings, roads, roads, etc., can solve the problems of poor sealing of installation holes, corrosion of plate steel bars, and short service life, and achieve favorable vibration reduction, smooth and seamless surfaces, and convenient construction quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

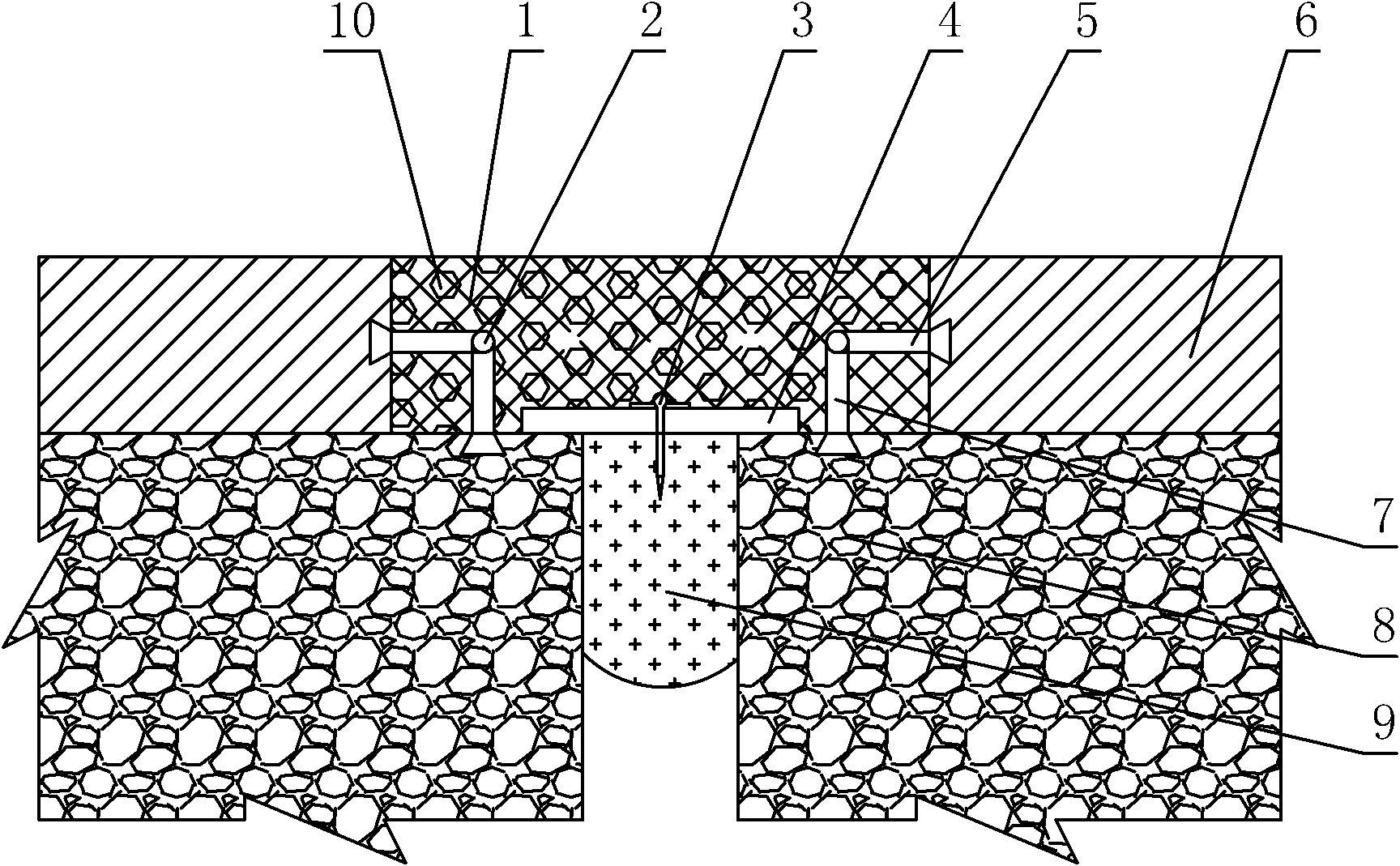

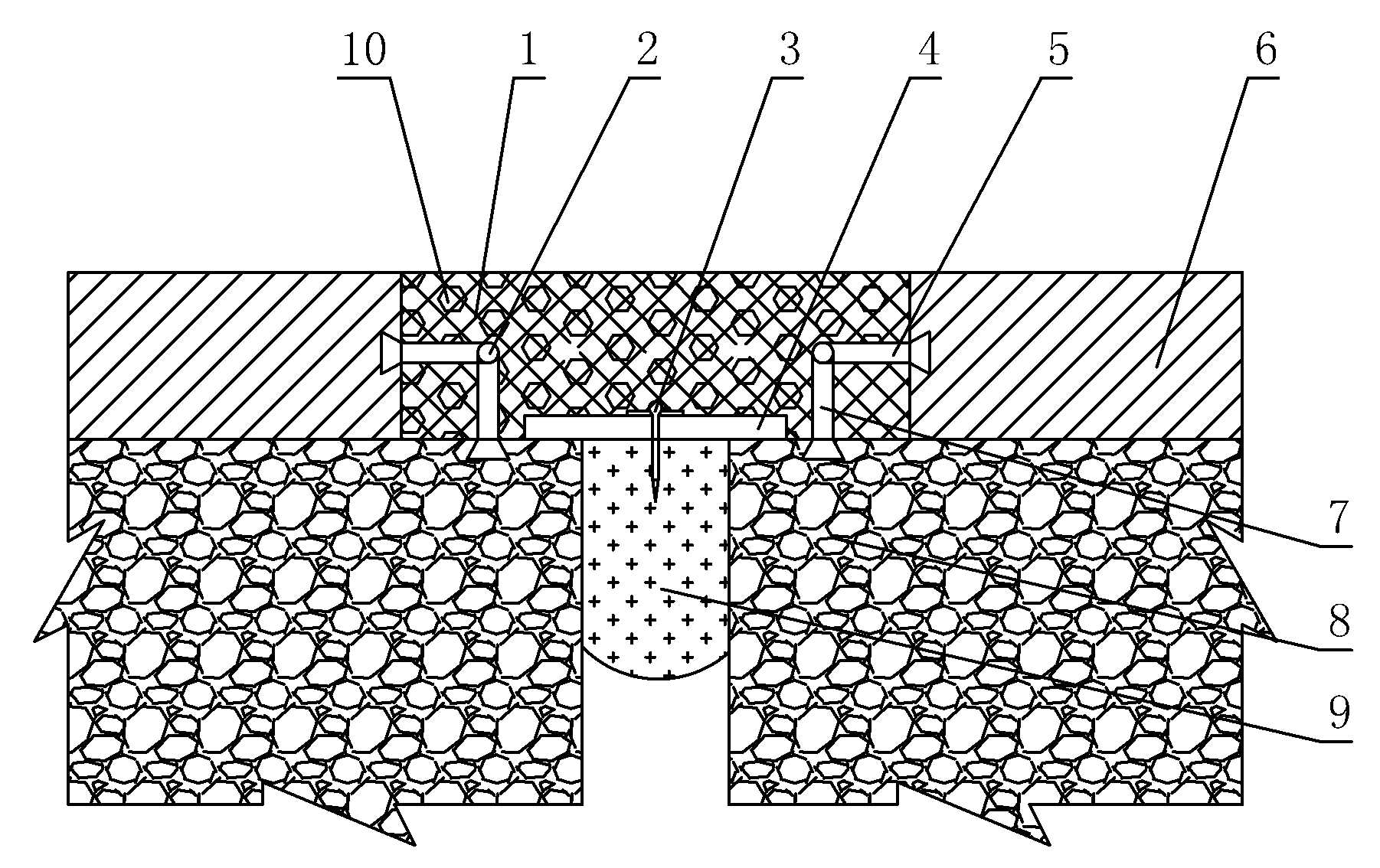

[0029] like figure 1 A kind of construction, road engineering expansion joint shown elastic-plastic body device comprises cast-in-place concrete layer 8 and the bituminous concrete pavement layer 6 that is arranged on the upper end of cast-in-place concrete layer 8, and the center of described cast-in-place concrete layer 8 is provided with Expansion joint, the inside of the expansion joint is filled with sponge body or foam body 9, the center of the asphalt concrete pavement layer 6 is provided with a notch, and the notch is filled with stretchable elastic body 1 and gravel 10, and the gravel 10 is evenly distributed in the stretchable elastic body 1, and a cover plate 4 is also arranged in the notch, and the cover plate 4 is located at the upper end of the expansion joint, and the cover plate 4 is fixedly connected with the sponge body or the foam body 9; Lower expansion bolts 7 are symmetrically arranged on the upper part of the cast-in-place concrete layer 8, and side expa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com