A conveying and leveling device for printing textile fabrics

A technology of textile fabrics and leveling device, which is applied in textile and papermaking, fabric surface trimming, cleaning by electrostatic method, etc., can solve the problems of poor cleaning and ironing effect, difficult to eliminate wrinkles on printed fabrics, etc., and achieves good leveling effect, Ironing effect is good, the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

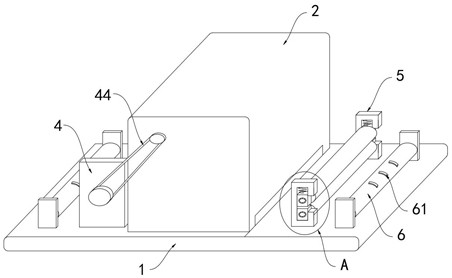

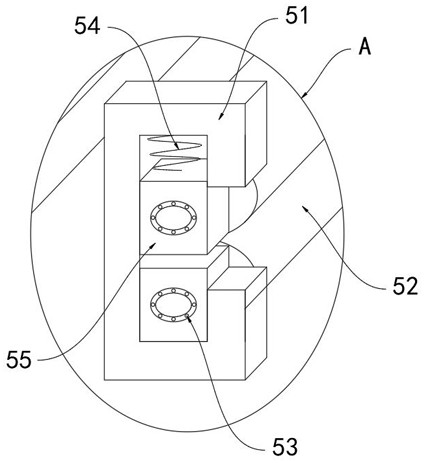

[0030] Refer to attached Figure 1-4 , a conveying and leveling device for printed textile fabrics, comprising a workbench 1, the upper surface of the workbench 1 is fixedly connected with a whole cloth box 2, and a leveling mechanism 3 is arranged in the whole cloth box 2, and a leveling mechanism 3 is installed on the workbench 1 There are cleaning agencies4.

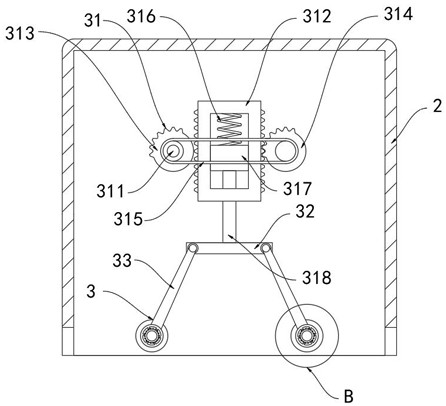

[0031] Specifically, the leveling mechanism 3 includes a driving assembly 31, a pressing plate 32, a deflection rod 33, a ratchet 34, a pawl 35, and a smoothing roller 36. The output end of the driving assembly 31 is connected to the pressing plate 32 for driving the pressing plate 32 in the vertical direction. Moving up and down, the side walls on both sides of the pressing plate 32 are hinged with deflection rods 33, and the roller shafts of the two leveling rollers 36 are coaxially fixedly connected with ratchets 34, and the lower ends of the two deflection rods 33 are connected with the two leveling rollers respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com