Neutral oil and rust removing detergent used for agreeing with coating pretreatment production takt and preparation method

A technology of rust removal cleaning agent and production cycle, which is applied in the field of neutral degreasing and rust removal cleaning agent and preparation in line with the production cycle of pre-painting treatment, which can solve the problems of affecting the production cycle and slow speed of oil and rust removal Improve the appearance of pre-treatment, improve the mechanical properties and corrosion resistance, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of a neutral degreasing and derusting cleaning agent suitable for the production cycle of pre-painting treatment, comprising the following steps: (1) mixing organic acid and water evenly; (2) adding corrosion inhibitor In the mixed solution of step (1), fully stir until the solution is clear and transparent; (3) join the chelate compound in the mixed solution of step (2), fully stir until the solution is clear and transparent; (4) in step ( 3) In the mixed solution, add inorganic salts to adjust the pH to 6.5-7.5; (5) After the mixed solution in step (4) is fully stirred until the solution is clear and transparent, and the temperature of the solution is cooled to below 50°C, add a surfactant , and then stir well to complete the preparation.

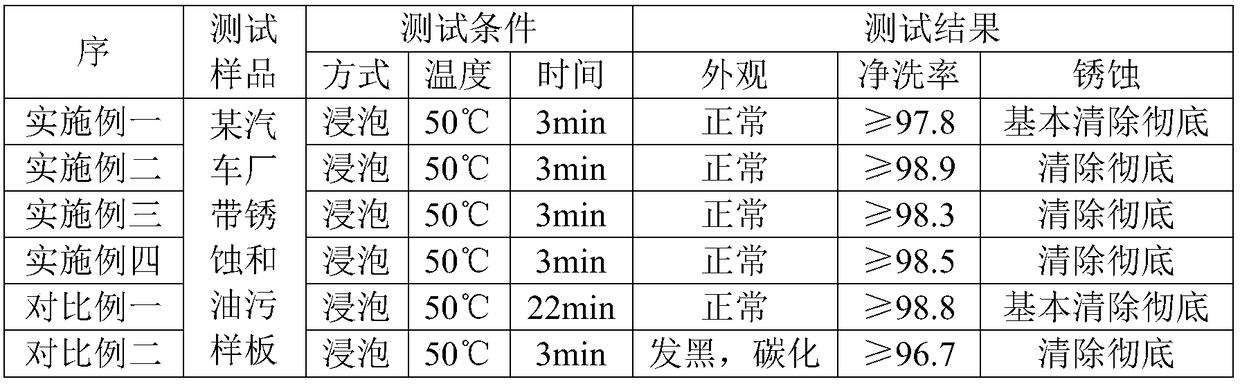

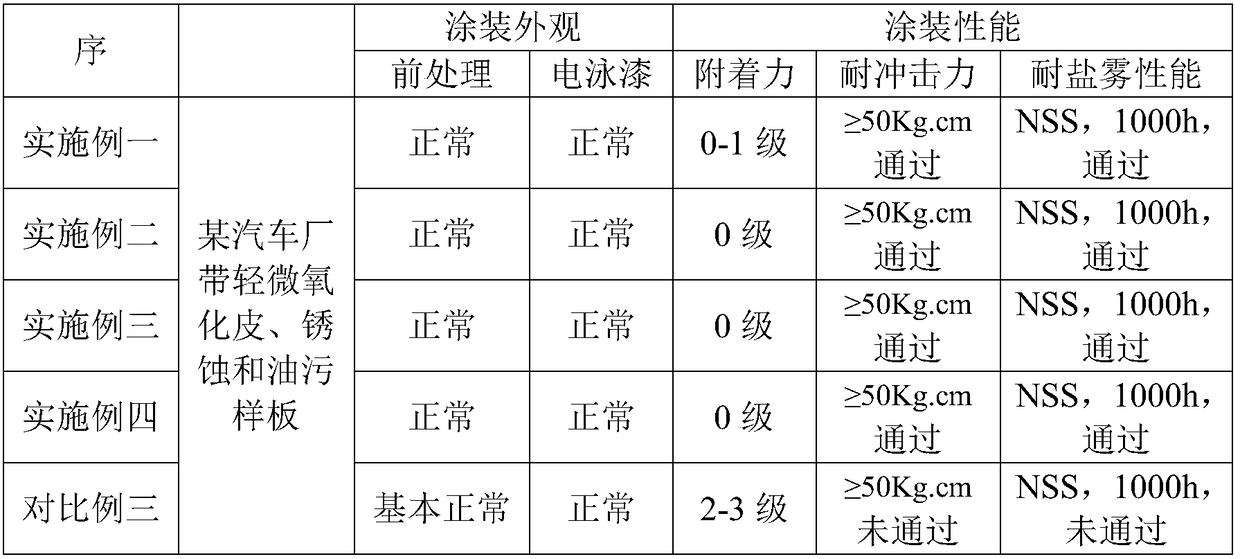

[0033] The reference technical indicators of the neutral degreasing and derusting cleaning agent described in the embodiment of the present invention in line with the product...

Embodiment 1

[0041] Prepare 100kg of a cleaning agent for degreasing and rust removal according to the production rhythm of pre-painting treatment. Its raw materials are as follows: inorganic salt KOH 10kg, organic acid citric acid 25kg, chelate phytic acid 8kg, surfactant fatty alcohol Polyoxyethylene ether (n=7) 1kg, surface active sodium stearate 1kg, corrosion inhibitor organic amine ester TPP 1kg, and the balance is water. Weigh each raw material with the above weight, first mix the organic acid and water, fully stir evenly, then add the corrosion inhibitor, fully stir until the solution is clear and transparent, then add the chelate compound, fully stir until the solution is clear and transparent, then add Inorganic salt, adjust pH=6-7, stir well until the solution is clear and transparent, after the temperature of the solution is cooled to below 50°C, finally add the surfactant, and then the above-mentioned suitable for pre-painting treatment production cycle can be obtained. Rust c...

Embodiment 2

[0043] Prepare 100kg of a cleaning agent for degreasing and derusting that meets the production rhythm of pre-painting treatment of the present invention, and its raw material composition is as follows: inorganic salt K 2 CO 3 20kg, organic acid tartaric acid 35kg, chelate HEDP 12kg, surfactant fatty alcohol polyoxyethylene ether (n=7) 3kg, surface active sodium stearate 2kg, corrosion inhibitor organic amine ester TPP 3kg, and the balance is water. Weigh each raw material with the above weight, first mix the organic acid and water, fully stir evenly, then add the corrosion inhibitor, fully stir until the solution is clear and transparent, then add the chelate compound, fully stir until the solution is clear and transparent, then add Inorganic salt, adjust pH=6-7, stir well until the solution is clear and transparent, after the temperature of the solution is cooled to below 50°C, finally add the surfactant, and then the above-mentioned suitable for pre-painting treatment produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com