Tackle circulating transporting device and conveying method thereof

A technology of cyclic conveying and pulleys, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of occupying a large space in the Z direction, achieve the effects of reducing the size of space, reducing the number of pulleys, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

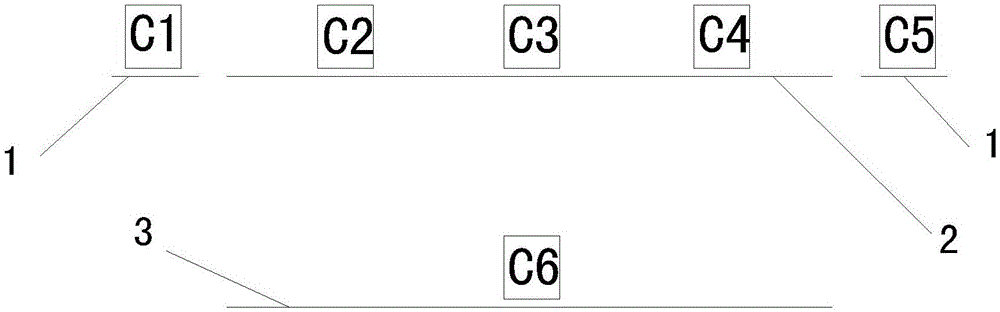

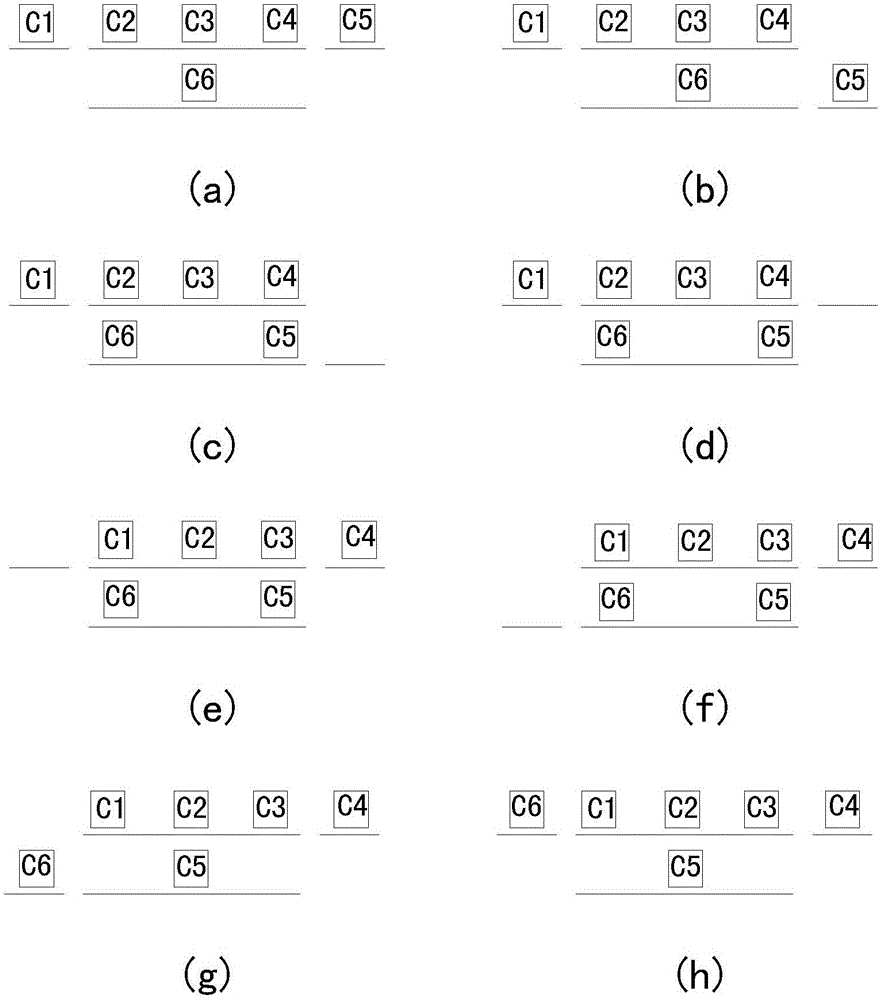

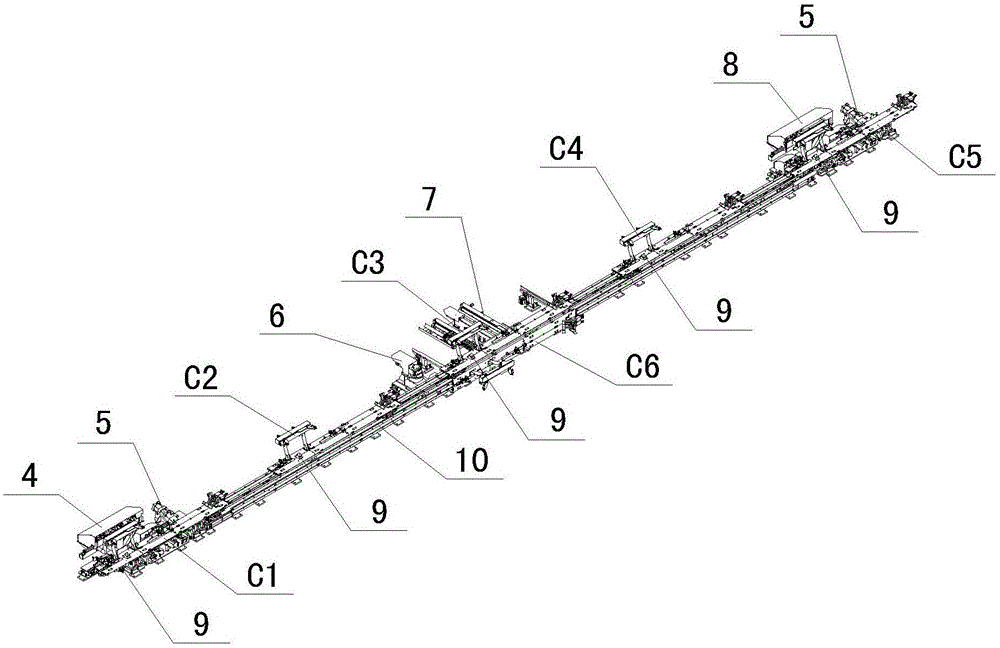

[0036] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a pulley locking workpiece external force device 4, a pulley loosening a workpiece external force device 8, a pulley transferred to a clamp switching device 7, a pulley control mechanism 9, a pulley movement mechanism 6, a track 10 and multiple devices arranged on the track 10 track 10 includes a movable track 1 and a fixed track 10, and the fixed track 10 includes a conveying track 2 and a return track 3 parallel to each other, and a movable track switching device 5 is arranged between the movable track 1 and the fixed track 10, and the conveying track 2 is used To transport the trolley from the upper station to the lower station, the return track 3 is used to return the trolley, and the movable track 1 is used to switch the trolley between the delivery track 2 and the return track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com