Solder strip pre-stretching mechanism

A technology of pre-stretching and welding strips, which is applied in the field of automation equipment, can solve the problems of affecting the production rhythm of the equipment, reducing the production capacity of the stringer, and the long running time, so as to improve the production capacity of the stringer, compact operation time, and close the operation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings.

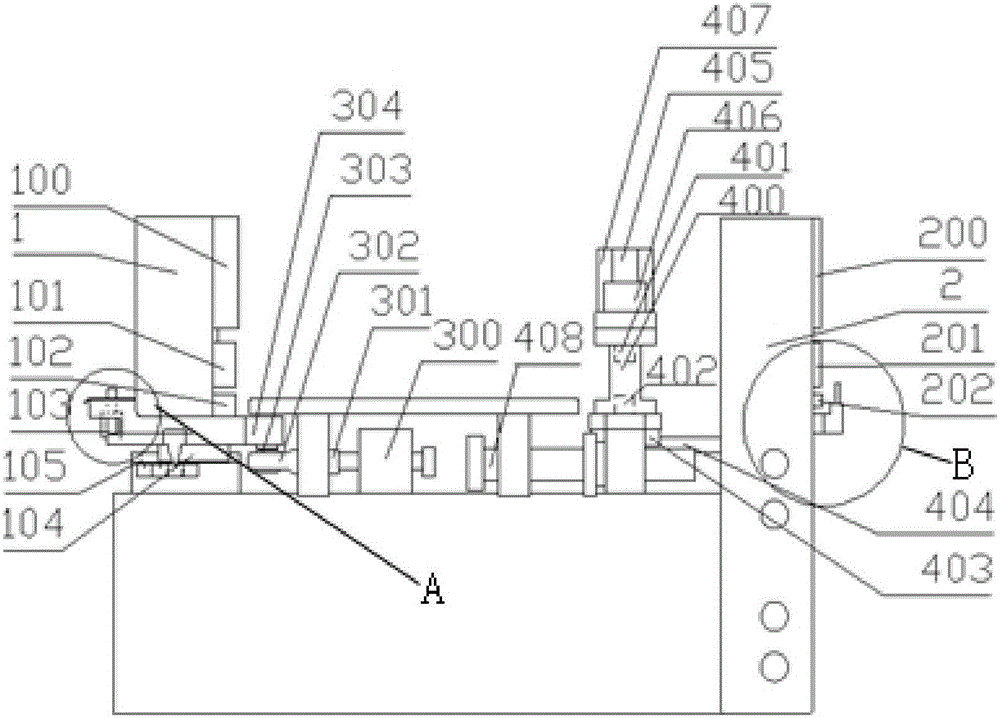

[0025] The ribbon pre-stretching mechanism of the present invention is used to complete the stretching of the ribbon before the ribbon fetching mechanism takes the ribbon and puts the battery sheet, so as to avoid affecting the beat of the whole machine. When describing the following specific embodiments, the coordinate system refers to figure 1 ,by figure 1 The left and right direction in the figure is left and right, the up and down direction is up and down, the direction perpendicular to the outside of the paper is front, and the direction perpendicular to the inside of the paper is back. The ribbon pre-stretching mechanism mainly includes a supporting structure, a pressing mechanism and a stretching mechanism, and the pressing mechanism and the stretching mechanism are arranged on the supporting structure.

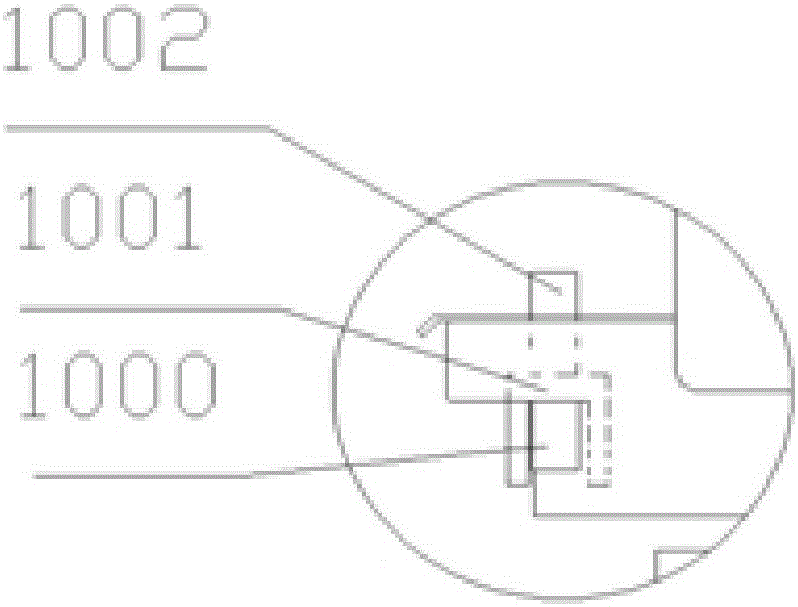

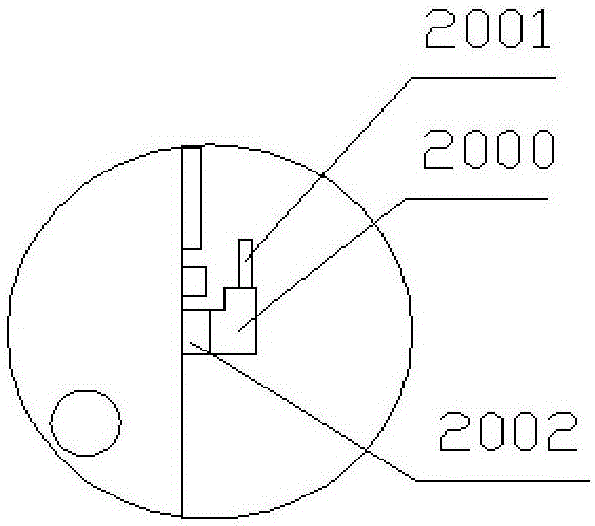

[0026] There are two pressing mechanisms, namely the first pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com