Detection device for liquid crystal display panel of touch screen production technology

A liquid crystal panel and detection device technology, applied in the detection field, can solve the problem that the touch screen is not feasible for mass production, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

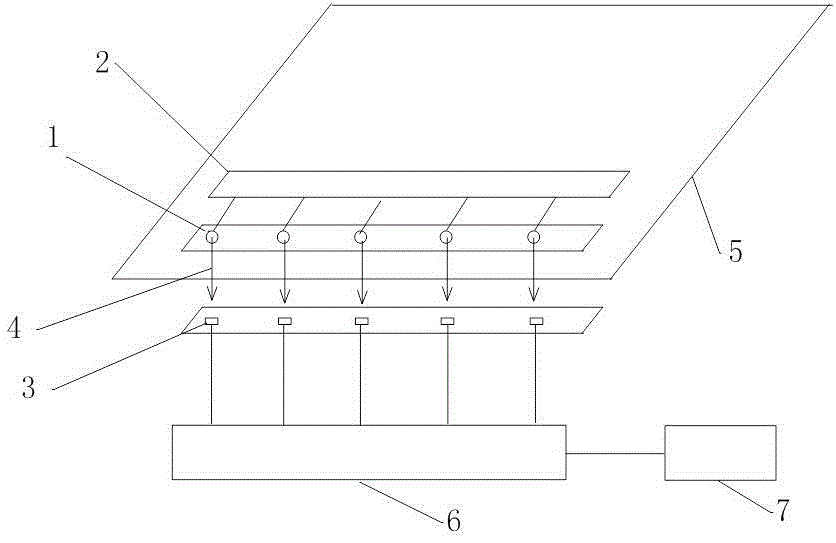

[0029] Such as figure 1 As shown, a detection device for a liquid crystal panel used in the production process of a touch screen, the detection device includes a light emitting system composed of several laser emitters and a laser controller, and a light emitting system composed of laser sensors matching the number of laser emitters The receiving system, the light processing device, the laser emitter and the laser sensor are respectively located above and below the liquid crystal panel, and the light processing device is connected with the light receiving system in a communication manner.

[0030] Further, the laser emitter is kept perpendicular to the liquid crystal panel and the laser thickness sensor.

[0031] Further, the laser emitters and laser sensors are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com