Stamping waste collection device

A waste collection and waste technology, applied in storage devices, feeding devices, positioning devices, etc., can solve the problems of strong professionalism, inability to collect waste, and low flexibility, and achieve waste collection without changing the layout and volume of the production line. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

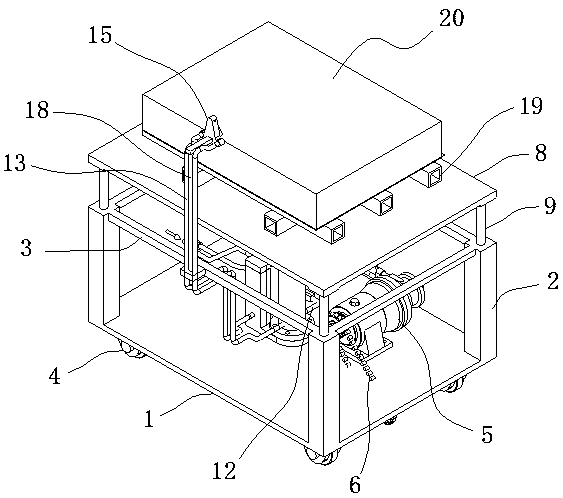

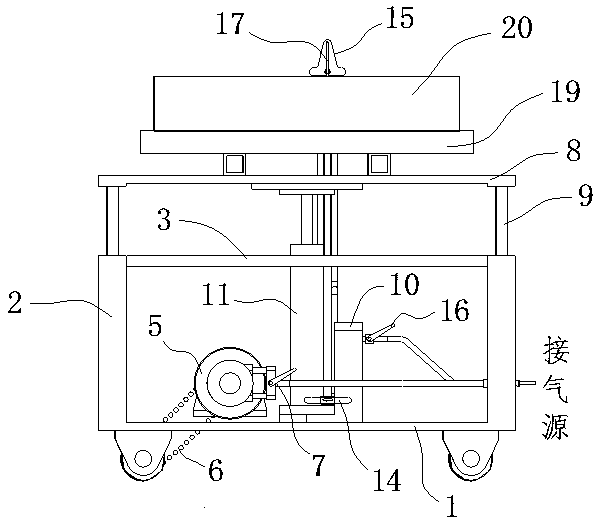

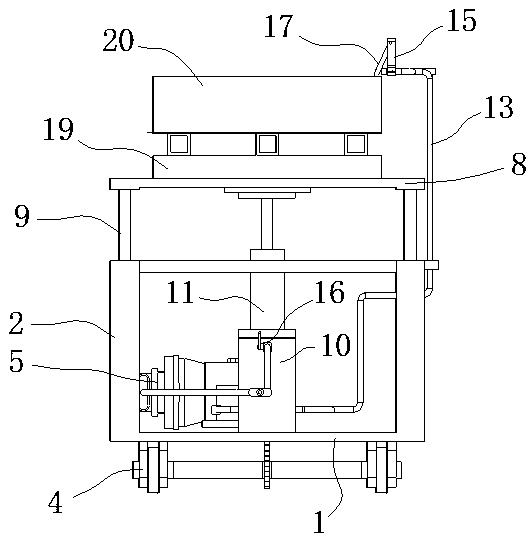

[0023] The stamping waste collection device of this embodiment is a non-standard automation equipment, which can realize the functions of waste collection, storage, transfer and other functions of the stamping professional automatic production line.

[0024] like Figure 1~4 As shown, the stamping waste collection device of this embodiment includes a frame; a traveling mechanism that drives the frame to move; a waste receiving platform installed on the frame through a lifting mechanism; a height adjustment mechanism, which is used for receiving waste materials on the waste receiving platform. When the height exceeds the predetermined height, reduce the height of the waste receiving platform.

[0025] The specific structure of each component will be described in detail below.

[0026] In this embodiment, the frame is composed of a rectangular base plate 1 and guide columns 2 vertically fixed to the four corners of the base plate 1. The top ends of adjacent guide columns 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com